Nissan Juke Service and Repair Manual : C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

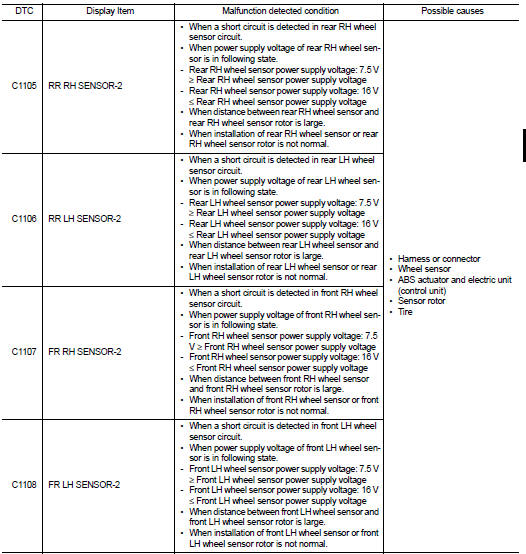

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Stat the engine.

2. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

3. Stop the vehicle.

4. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> Proceed to BRC-40, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

CAUTION:

Never check between wheel sensor harness connector terminals.

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY SYSTEM

Check ABS actuator and electric unit (control unit) power supply system. Refer to BRC-64, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK TIRE

1. Turn the ignition switch OFF.

2. Check tire air pressure, wear and size. Refer to WT-9, "Tire Air Pressure".

Is the inspection result normal? YES >> GO TO 5.

NO >> Adjust air pressure or replace tire and GO TO 3.

3.CHECK DATA MONITOR (1)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Stat the engine.

4. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

5. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM SELF-DIAGNOSIS (1)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 5.

NO >> INSPECTION END

5.CHECK WHEEL SENSOR

1. Turn the ignition switch OFF.

2. Check wheel sensor for damage.

3. Remove dust and foreign matter adhered to the sensor rotor with a vacuum dust collector through the wheel sensor mounting hole.

CAUTION:

Install wheel sensor with no backlash and float, and tighten the mounting bolt

to the specified

torque.

• Front: Refer to BRC-84, "FRONT WHEEL SENSOR : Exploded View".

• Rear: Refer to BRC-85, "REAR WHEEL SENSOR : Exploded View".

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 6.

6.REPLACE WHEEL SENSOR (1)

With CONSULT-III.

With CONSULT-III.

1. Replace wheel sensor.

- Front: Refer to BRC-84, "FRONT WHEEL SENSOR : Removal and Installation".

- Rear: Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation".

2. Erase Self-diagnosis result for “ABS”.

3. Turn the ignition switch OFF, and wait 10 seconds or more.

4. Stat the engine.

5. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

6. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 7.

NO >> GO TO 19.

7.PERFORM SELF-DIAGNOSIS (2)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 19.

NO >> INSPECTION END

8.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

3. Check wheel sensor harness connector for disconnection or looseness.

Is the inspection result normal? YES >> GO TO 11.

NO >> Repair or replace error-detected parts, securely lock the connector, and GO TO 9.

9.CHECK DATA MONITOR (2)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Stat the engine.

4. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

5. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 10.

NO >> GO TO 11.

10.PERFORM SELF-DIAGNOSIS (3)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 11.

NO >> INSPECTION END

11.CHECK TERMINAL

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector and then check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

3. Disconnect wheel sensor harness connector and check each wheel sensor pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair or replace error-detected parts and GO TO 12.

12.CHECK DATA MONITOR (3)

With CONSULT-III.

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect wheel sensor harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Stat the engine.

6. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

7. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 13.

NO >> GO TO 14.

13.PERFORM SELF-DIAGNOSIS (4)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 14.

NO >> INSPECTION END

14.CHECK WHEEL SENSOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Disconnect wheel sensor harness connector.

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> GO TO 15.

NO >> Repair or replace error-detected parts and GO TO 15.

15.CHECK DATA MONITOR (4)

With CONSULT-III.

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect wheel sensor harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Stat the engine.

6. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

7. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 16.

NO >> GO TO 17.

16.PERFORM SELF-DIAGNOSIS (5)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 17.

NO >> INSPECTION END

17.REPLACE WHEEL SENSOR

With CONSULT-III.

With CONSULT-III.

1. Replace wheel sensor.

- Front: Refer to BRC-84, "FRONT WHEEL SENSOR : Removal and Installation".

- Rear: Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation".

2. Erase Self-diagnosis result for “ABS”.

3. Turn the ignition switch OFF, and wait 10 seconds or more.

4. Stat the engine.

5. Select “ABS” and “DATA MONITOR”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and “RR RH SENSOR”.

NOTE

:

Set the “DATA MONITOR” recording speed to “10 msec”.

6. Read a value (wheel speed) of both normal wheel sensors and error-detecting wheel sensor.

Regarding the deference at 30 km/h (19 MPH) between the wheel speed detected by the error detecting wheel sensor and the maximum/minimum wheel speed detected by the normal wheel sensors, is the difference within 5%, respectively? YES >> GO TO 18.

NO >> GO TO 19.

18.PERFORM SELF-DIAGNOSIS (6)

With CONSULT-III.

With CONSULT-III.

1. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Stop the vehicle.

3. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> GO TO 19.

NO >> INSPECTION END

19.REPLACE SENSOR ROTOR

With CONSULT-III.

With CONSULT-III.

1. Replace sensor rotor.

- Front: Refer to BRC-84, "FRONT WHEEL SENSOR : Removal and Installation".

- Rear: Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation".

2. Erase Self-diagnosis result for “ABS”.

3. Turn the ignition switch OFF, and wait 10 seconds or more.

4. Stat the engine.

5. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

6. Stop the vehicle.

7. Perform self-diagnosis for “ABS”.

Is DTC “C1105”, “C1106”, “C1107” or “C1108” detected? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-90, "Removal and Installation".

NO >> INSPECTION END

C1101, C1102, C1103, C1104 WHEEL SENSOR

C1101, C1102, C1103, C1104 WHEEL SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

C1109 power and ground system

C1109 power and ground system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Diagnosis and repair work flow

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing BRC-146, "Diagnostic

Work Sheet" and reproduce the symptom as well as fully understand it. Ask

customer about his/her complaints

carefu ...

Back door lock

Exploded View

1. Back door lock assembly

2. TORX bolt

3. Back door striker

: Do not reuse

: N·m (kg-m, ft-lb)

: Body grease

Door lock

DOOR LOCK : Removal and Installation

REMOVAL

1. Remove the back door lower finisher. Refer to INT-35, "BACK DOOR LOWER

FINISHER : Removal and

Ins ...

U0122 Vehicle dynamics control

module

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each c ...