Nissan Juke Service and Repair Manual : P2765 clutch B speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 seconds or more.

Selector lever : “D” position Vehicle speed : 55 km/h (34 MPH) or more

4. Stop the vehicle

5. Check the first trip DTC.

Is “P2765” detected? YES >> Go to TM-461, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK SECONDARY SPEED SENSOR POWER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect secondary speed sensor connector.

3. Turn ignition switch ON.

4. Check the voltage between the secondary speed sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 6.

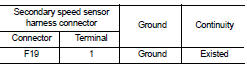

2.CHECK SECONDARY SPEED SENSOR GROUND CIRCUIT

Check continuity between of the primary speed sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK CIRCUIT BETWEEN SECONDARY SPEED SENSOR AND TCM (PART 1)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check continuity between the secondary speed sensor harness connector terminal and the TCM harness connector terminal.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK CIRCUIT BETWEEN SECONDARY SPEED SENSOR AND TCM (PART 2)

Check continuity between the secondary speed sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CHECK TCM INPUT SIGNALS

1. Connect all of the disconnected connectors.

2. Lift the vehicle.

3. Start the engine.

4. Check frequency of secondary speed sensor.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the secondary speed sensor. TM-496, "Removal and Installation".

6.CHECK CIRCUIT BETWEEN IPDM E/R AND SECONDARY SPEED SENSOR (PART 1)

1. Disconnect the IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector terminal and secondary speed sensor harness connector terminal.

Is the check result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

7.CHECK CIRCUIT BETWEEN IPDM E/R AND SECONDARY SPEED SENSOR (PART 2)

Check continuity between IPDM E/R harness connector terminal and ground.

Is the check result normal? YES >> GO TO 8.

NO >> Repair or replace the malfunctioning parts.

8.DETECTION OF MALFUNCTION ITEMS

Check the following items: • Harness open circuit or short circuit between the ignition switch and IPDM E/R. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

• 10A fuse (No.55, IPDM E/R). Refer to PG-25, "Fuse, Connector and Terminal Arrangement".

• IPDM E/R

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

P17BB primary pressure solenoid

P17BB primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Main power supply and ground circuit

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT 1

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the voltage between the TCM harness connector terminals and ground.

Is ...

Other materials:

Front seat (2WD)

Exploded View

DRIVER SEAT

LHD models

1. Headrest

2. Headrest holder (locked)

3. Headrest holder (free)

4. Seatback heater unit

5. Inner lower cover

6. Seatback trim

7. Seatback pad

8. Seat cushion inner finisher

9. Reclining device inner cover

10. Anchor bolt

11. Seat belt buck ...

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT 1

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the voltage between the TCM harness connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK TCM POWER C ...

Diagnosis system (audio unit)

Models with usb connection function

MODELS WITH USB CONNECTION FUNCTION : On Board Diagnosis Function

Self-diagnosis mode can check the following items.

METHOD OF STARTING

1. Start the engine.

2. Turn OFF audio.

3. While pressing the “SET UP” switch, turn the MENU dial counterclockwise

3 cl ...