Nissan Juke Service and Repair Manual : P0225 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE

:

• If DTC P0225 is displayed with DTC P0641, first perform trouble diagnosis for

DTC P0641. Refer to

EC-974, "DTC Logic".

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between accelerator pedal position sensor connector and ground

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

4.CHECK ACCELERATOR PEDAL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

6.CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

8.CHECK ACCELERATOR PEDAL POSITION SENSOR

Refer to EC-926, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace accelerator pedal position sensor.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

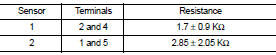

Component Inspection

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position sensor harness connector.

3. Check resistance between accelerator pedal position sensor as follows.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace accelerator pedal position sensor.

P0217 engine over temperature

P0217 engine over temperature

DTC Logic

DTC DETECTION LOGIC

If the cooling fan or another component in the cooling system malfunctions,

engine coolant temperature will

rise.

When the engine coolant temperature reaches an a ...

P0226 APP sensor

P0226 APP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

4WD warning lamp blinks slowly

Description

4WD warning lamp blinks at approximately 2 seconds intervals while driving.

Diagnosis Procedure

1.CHECK TIRE

Check the following.

• Tire pressure

• Wear condition

• Front and rear tire size (There is no difference between front and rear

tires.)

Is the inspection result normal ...

Diagnosis system (IPDM E/R)

Consult-III Function (IPDM E/R)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM

E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-25, "DTC Index".

DATA MONITOR

Monitor item

ACTIVE TEST

Test item

...

Precaution

Precautions for Drive Shaft

• Observe the following precautions when disassembling and assembling drive

shaft.

- Never disassemble joint sub-assembly because it is non-overhaul parts.

- Perform work in a location which is as dust-free as possible.

- Clean the parts, before disassembling and ...