Nissan Juke Service and Repair Manual : Oil cooler

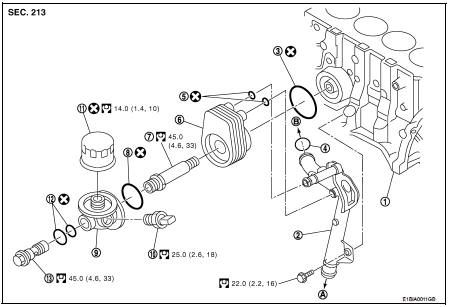

Exploded View

1. Cylinder block

2. Water pipe

3. O-ring

4. O-ring

5. O-ring

6. Oil cooler

7. Connecting stud

8. O-ring

9. Oil filter bracket

10. Oil pressure switch

11. Oil filter

12. O-ring

13. Connecting bolt

A. : To radiator lower hose B. : To water pump

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

CAUTION:

• Be careful not to get burned when the engine and engine oil are hot.

• When removing, prepare a shop cloth to absorb any oil leakage or spillage.

• Completely wipe off any oil that abhere to the engine and the vehicle.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-62, "Draining".

CAUTION:

Perform when engine is cold.

2. Remove oil filter and oil filter bracket. Refer to LU-35, "Exploded View".

3. Remove alternator.

4. Remove oil cooler.

INSTALLATION

Installation is in reverse order of removal.

• Replace the O-ring (A) of the oil cooler, positioning the lip (B) of the seal behind the lug (C) of the oil cooler.

• Confirm that no foreign objects are adhering to the installation planes of the oil cooler and block.

Inspection

Oil Cooler

Check oil cooler for cracks and clogging by blowing through coolant inlet. If

necessary, replace oil cooler

assembly.

Oil pump

Oil pump

Exploded View

1. Oil pump drive chain

2. Crankshaft sprocket

3. Oil pump assembly

Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Remove eng ...

Service data and specifications

(SDS)

Service data and specifications

(SDS)

Standard and Limit

OIL PRESSURE

OIL CAPACITY (APPROXIMATE)

TIGHTENING TORQUE

...

Other materials:

Charging system preliminary inspection

Inspection Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair battery terminals connection.

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection resu ...

Oil filter

Exploded View

1. O-ring

2. Oil filter bracket

3. Oil pressure switch

4. Oil filter

5. O-ring

6. Connecting bolt

A. To oil cooler

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Using an oil filter wrench [SST:KV113C0010 (Mot.1329) ...

P0102, P0103 MAF SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 seconds before conducting the next test.

Which DTC is detected?

P0102 >> GO TO 2.

P0103 & ...