Nissan Juke Service and Repair Manual : Trouble diagnosis

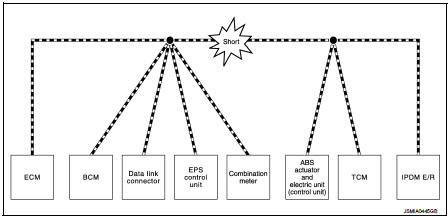

System Diagram

Condition of Error Detection

DTC (e.g. U1000 and U1001) of CAN communication is indicated on SELF-DIAG RESULTS on CONSULT-III if a CAN communication signal is not transmitted or received between units for 2 seconds or more.

CAN COMMUNICATION SYSTEM ERROR

• CAN communication line open (CAN-H, CAN-L, or both)

• CAN communication line short (ground, between CAN communication lines, other

harnesses)

• Error of CAN communication control circuit of the unit connected to CAN

communication line

WHEN DTC OF CAN COMMUNICATION IS INDICATED EVEN THOUGH CAN COMMUNICATION SYSTEM IS NORMAL

• Removal/installation of parts: Error may be detected when removing and

installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN

communication may be

detected.)

• Fuse blown out (removed): CAN communication of the unit may cease.

• Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition switch ON (Depending on the control unit which carries out CAN communication).

• Error may be detected if the power supply circuit of the control unit, which carries out CAN communication, malfunctions (Depending on the control unit which carries out CAN communication).

• Error may be detected if reprogramming is not completed normally.

CAUTION

:

CAN communication system is normal if DTC of CAN communication is indicated on

SELF-DIAG

RESULTS of CONSULT-III under the above conditions. Erase the memory of the

self-diagnosis of each

unit.

Symptom When Error Occurs in CAN Communication System

In CAN communication system, multiple units mutually transmit and receive signals. Each unit cannot transmit and receive signals if any error occurs on CAN communication line. Under this condition, multiple control units related to the root cause malfunction or go into fail-safe mode.

ERROR EXAMPLE

NOTE

:

Each vehicle differs in symptom of each unit under fail-safe mode and CAN

communication line wiring.

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: TCM Branch Line Open Circuit

NOTE

:

The model (all units on CAN communication system are Diag on CAN) cannot perform

CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

Example: Data Link Connector Branch Line Open Circuit

NOTE

:

When data link connector branch line is open, transmission and reception of CAN

communication signals are

not affected. Therefore, no symptoms occur. However, be sure to repair

malfunctioning circuit.

Example: CAN-H, CAN-L Harness Short Circuit

Can diagnosis with consult-III

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following information.

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• CAN diagnostic support monitor

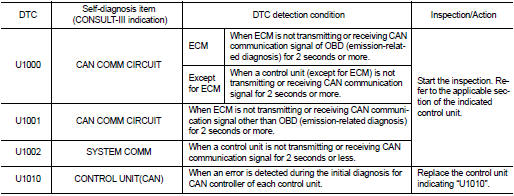

Self-Diagnosis

If communication signals cannot be transmitted or received among units communicating via CAN communication line, CAN communication-related DTC is displayed on the CONSULT-III “Self Diagnostic Result” screen.

NOTE

:

The following table shows examples of CAN communication-related DTC. For other

DTC, refer to the applicable

sections.

Can Diagnostic Support Monitor

MONITOR ITEM (CONSULT-III)

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

How to Use Can Communication Signal Chart

The CAN communication signal chart lists the signals needed for trouble diagnosis. It is useful for detecting the root cause by finding a signal related to the symptom, and by checking transmission and reception unit.

System

System

Can communication system

CAN COMMUNICATION SYSTEM : System Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

commun ...

Basic inspection

Basic inspection

Diagnosis and repair workflow

Trouble Diagnosis Flow Chart

Trouble Diagnosis Procedure

INTERVIEW WITH CUSTOMER

Interview with the customer is important to detect the root cause of CAN

communic ...

Other materials:

Power supply and ground circuit

AUDIO UNIT

AUDIO UNIT : Diagnosis Procedure

1.CHECK FUSE

Check for blown fuses.

Is inspection result OK?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between audio unit harness connect ...

C1116 stop lamp switch

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...