Nissan Juke Service and Repair Manual : Removal and installation

ALTERNATOR

HR16DE

HR16DE : Exploded View

REMOVAL

1. Alternator bracket mounting bolt

2. Alternator bracket

3. Alternator mounting bolt

4. Alternator

5. “B” terminal harness

6. “B” terminal nut

7. Alternator connector

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

Type: A002TJ1291ZE

1. Rear bearing

2. Rotor assembly

3. Retainer

4. Front bearing

5. Front bracket assembly

6. Pulley

7. Pulley nut

8. Stator assembly

9. IC voltage regulator assembly

10. Diode assembly

11. Rear bracket assembly

12. Terminal set

:

:

Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

HR16DE : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124, "Removal and Installation".

2. Remove radiator reservoir tank. Refer to CO-17, "Exploded View".

3. Remove drive belt. Refer to EM-155, "Removal and Installation".

4. Disconnect alternator connector.

5. Remove “B” terminal nut and disconnect “B” terminal harness.

6. Remove alternator mounting bolts.

7. Remove alternator upward from the vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Temporarily tighten the alternator bolts in order from the lower to the upper,

and then tighten them in

order from the upper to the lower.

• For the alternator, the front side (pulley side) surface is the reference surface. Fit the reference surface to the alternator mounting part, and then tighten the bolts.

• Be careful to tighten “B” terminal nut carefully.

• Install alternator, and check tension of belt. Refer to EM-154, "Checking".

NOTE:

Tighten mounting bolts according to the following procedures for installing alternator bracket.

1. Temporarily tighten mounting bolt (1).

2. Temporarily tighten mounting bolt (2).

3. Tighten mounting bolts in numerical order as shown in the figure.

HR16DE : Disassembly and Assembly

DISASSEMBLY

Rear Cover

NOTE

:

Rear cover may be hard to remove because a ring is used to lock

outer race of rear bearing. To facilitate removal of rear cover, heat

only the bearing box section until the temperature increases to

approximately 30°C (86°F) with a soldering iron (200W capacity).

CAUTION:

Never use a heat gun, as if can damage diode assembly.

ASSEMBLY

Rear Bearing

CAUTION:

• Never reuse rear bearing. Replace with a new one.

• Never lubricate rear bearing outer race.

Rear Cover Installation 1. Fit brush assembly, diode assembly, regulator assembly and stato

2. Push brushes up with fingers and install them to rotor.

NOTE

:

Take care not damage slip ring sliding surface.

HR16DE : Inspection

INSPECTION

Rotor Check

1. Resistance test

Resistance : Refer to SDS CHG-35, "Alternator".

• Replace the rotor if the measurement value is outside of the specified range.

2. Insulator test

• Replace the rotor if continuity exists.

3. Check slip ring for wear.

Slip ring minimum outer diameter : Refer to SDS CHG-35, "Alternator".

• Replace the rotor if the measurement value is outside of the specified range.

Brush Check

1. Check smooth movement of brush.

• Check brush holder and clean if it is not smooth.

2. Check brush for wear.

• Replace brush if it is worn down to the limit line.

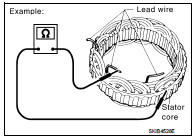

Stator Check

1. Continuity test

• Replace the stator if continuity does not exist.

2. Ground test

• Replace the stator if continuity exists.

MR16DDT

MR16DDT : Exploded View

REMOVAL

1. Alternator connector

2. Alternator mounting bolt (upper)

3. Alternator mounting bolt (lower)

4. Alternator

5. “B” terminal harness

6. “B” terminal nut

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

Type: A002TJ1381

1. Rear bearing

2. Rotor assembly

3. Retainer

4. Front bearing

5. Front bracket assembly

6. Pulley

7. Pulley cap

8. Stator assembly

9. IC voltage regulator assembly

10. Diode assembly

11. Rear bracket assembly

12. Terminal set

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

MR16DDT : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124, "Removal and Installation".

2. Remove charge air cooler. Refer to EM-31, "Removal and Installation".

3. Remove drive belt. Refer to EM-20, "Removal and Installation".

4. Disconnect alternator connector.

5. Remove “B” terminal nut and disconnect “B” terminal harness.

6. Remove alternator mounting bolt (upper).

7. Completely loosen alternator mounting bolt (lower), and pull it out until the bolt head is in contact with the side member. And then, remove the alternator by pulling it forward.

NOTE

:

The alternator can be removed together with the bolts by pulling it forward and

using the thermostat housing

bolt hole cutout.

8. Remove alternator forward from the vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Temporarily tighten the alternator bolts in order from the lower to the upper,

and then tighten them in

order from the upper to the lower

. • For the alternator, the front side (pulley side) surface is the reference surface. Fit the reference surface to the alternator mounting part, and then tighten the bolts.

• Be careful to tighten “B” terminal nut carefully.

• Install alternator, and check tension of belt. Refer to EM-20, "Checking".

• For this model, the power generation voltage variable control system that controls the power generation voltage of the alternator has been adopted. Therefore, the power generation voltage variable control system operation inspection should be performed after replacing the alternator, and then make sure that the system operates normally. Refer to CHG-18, "Inspection Procedure".

MR16DDT : Disassembly and Assembly

DISASSEMBLY

Rear Cover

NOTE

:

Rear cover may be hard to remove because a ring is used to lock

outer race of rear bearing. To facilitate removal of rear cover, heat

only the bearing box section until the temperature increases to

approximately 30°C (86°F) with a soldering iron (200W capacity).

CAUTION:

Never use a heat gun, as if can damage diode assembly.

Front Cover

1. Set rotor to the vise.

CAUTION:

• Be careful not to damage the rotor.

• Use copper plate or thick cloth for rotor in the vise.

2. Remove pulley cap, using suitable tool.

![3. Remove alternator pulley, using alternator pulley adaptor [SST].](images/books/335/59/7.html72.gif)

3. Remove alternator pulley, using alternator pulley adaptor [SST].

ASSEMBLY

Rear Bearing

CAUTION:

• Never reuse rear bearing. Replace with a new one.

• Never lubricate rear bearing outer race.

Rear Cover Installation

1. Fit brush assembly, diode assembly, regulator assembly and stator assembly.

2. Push brushed up with fingers and install them to rotor.

NOTE

:

Take care not damage slip ring sliding surface.

MR16DDT : Inspection

INSPECTION AFTER DISASSEMBLY

Rotor Check

1. Resistance test

Resistance : Refer to SDS CHG-35, "Alternator".

• Replace the rotor if the measurement value is outside of the specified range.

2. Insulator test

• Replace the rotor if continuity exists.

3. Check slip ring for wear.

Slip ring minimum outer diameter : Refer to SDS CHG-35, "Alternator".

• Replace the rotor if the measurement value is outside of the specified range.

Brush Check

1. Check smooth movement of brush.

• Check brush holder and clean if it is not smooth.

2. Check brush for wear.

• Replace brush if it is worn down to the limit line.

Stator Check

1. Continuity test

• Replace the stator if continuity does not exist.

2. Ground test

• Replace the stator if continuity exists.

Symptom diagnosis

Symptom diagnosis

CHARGING SYSTEM

Symptom Table

...

Service data and specifications (SDS)

Service data and specifications (SDS)

Alternator

*: Adjustment range of power generation voltage variable control is 11.4 −

15.6 V. ...

Other materials:

Insufficient heating

Description

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis Procedure

NOTE:

Perform self-diagnoses with CONSULT-III before performing symptom diagnosis. If

any DTC is detected, perform

the corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. ...

B2632, B2633 air mix door motor PBR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” mode of “HVAC” using CONSULT-III.

3. Check DTC.

Is DTC detected?

YES >> Refer to HAC-155, "Diagnosis P ...

DLC branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the data link connector for damage,

bend and loose connection

(connector side and harness side).

Is the inspection res ...