Nissan Juke Service and Repair Manual : Parking brake shoe

Exploded View

1. Anti-rattle pin

2. Back plate

3. Toggle lever

4. Parking brake shoe

5. Brake strut

6. Return spring

7. Spring

8. Adjuster

: Apply PBC (Poly Butyl

: Apply PBC (Poly Butyl

Cuprysil) grease or silicone-based grease.

Removal and Installation

REMOVAL

WARNING:

Clean any dust from the parking brake shoes and back plates with a vacuum dust

collector. Never

blow with compressed air.

1. Remove rear tires.

2. Remove disc rotor.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

CAUTION:

Parking brake completely in the released position.

3. Remove return spring (1) of the upper side.

4. Remove return spring (1) of the lower side.

5. Remove spring (1).

CAUTION:

Never drop the removed p

arts.

6. Remove parking brake shoes, adjuster, brake strut and toggle lever.

CAUTION:

• The parking brake shoes for the front wheels are made of

different materials from those for the rear wheels. Never

misidentify them when removing.

• Never drop the removed parts.

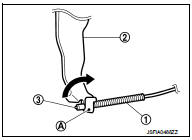

7. Press the rear cable spring (1) against spring tension to remove rear cable (3) from the clamp (A) of toggle lever (2).

CAUTION:

Never bend rear cable

.

8. For the removal of back plate.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

INSTALLATION

Note the following, install in the reverse order of removal.

• Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the back plate and brake shoe.

CAUTION:

The parking brake shoes for the front wheels are made of different materials

from those for the rear

wheels. Never misidentify them when removing and replacing.

• Assemble adjusters so that threaded part is expanded when rotating it in the direction shown by arrow.

A : For right side brake

B : For left side brake

: Vehicle front

: Vehicle front

: Adjuster expands

: Adjuster expands

• Shorten adjuster by rotating it.

• When disassembling apply PBC (Poly Butyl Cuprysil) grease or silicone- based grease to threads.

• Check that the component parts of the parking brake shoe are properly installed.

• Check brake shoe sliding surface and drum inner surface for grease. Wipe it off if it adhere on the surfaces.

Inspection and Adjustment

INSPECTION AFTER REMOVAL

Lining Thickness Inspection • Check thickness (A) of lining.

A : Refer to PB-11, "Parking Drum Brake".

Drum Inner Diameter Inspection • Check inner diameter (B) of drum.

B : Refer to PB-11, "Parking Drum Brake".

Other Inspections

Check the following items, and replace the parts if necessary.

• Lining for excessive wear, damage, and peeling.

• Brake shoe sliding surface for excessive wear and damage.

• Anti-rattle pin for excessive wear, damage and rust.

• Return spring and spring for settling, excessive wear, damage, and rust.

• Adjuster for smoothness.

• Toggle lever and brake strut for excessive wear, damage and rust.

• Visually check inside of the drum for excessive wear, cracks, and damage with a pair of vernier calipers.

ADJUSTMENT AFTER INSTALLATION

1. Adjust the parking brake lever stroke. Refer to PB-2, "Inspection and Adjustment".

2. Rotate the disc rotor to check that there is no drag. Install the plug. If any drag is found, follow the procedure described below.

a. Adjust parking brake stroke again.

b. Check rear disc brake.

• LHD: Refer to BR-68, "BRAKE CALIPER ASSEMBLY : Inspection".

• RHD: Refer to BR-134, "BRAKE CALIPER ASSEMBLY : Inspection".

3. Adjust the parking brake shoe. Refer to PB-3, "Adjustment".

Parking brake control

Parking brake control

Exploded View

2WD

1. Parking brake lever assembly

2. Adjusting nut

3. Parking brake switch

4. Front cable

5. Rear cable (LH)

6. Rear cable (RH)

: Apply multi-purpose grease.

: N·m (kg-m ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Parking Drum Brake

Parking Brake Control

...

Other materials:

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

• After removing mounting nuts and bolts, separate the mating surface

using the seal cutter [SST: KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100 (J- ...

Component parts

Component Parts Location

1. Back door lock assembly

2. Front door lock assembly (driver

side)

3. Front door switch (driver side)

4. Power window main switch

(door lock/unlock switch)

5. Key switch

6. Combination meter

7. Door lock status indicator

8. Remote keyless entry receiver

9. ...

Engine unit

Disassembly

1. Remove intake manifold. Refer to EM-28, "Exploded View".

2. Remove catalyst convertor. Refer to EM-33, "2WD : Exploded View" (2WD models)

or EM-34, "4WD :

Exploded View" (4WD models).

3. Remove turbocharger. Refer to EM-36, "Exploded View" ...