Nissan Juke Service and Repair Manual : P2100 electric throttle control function

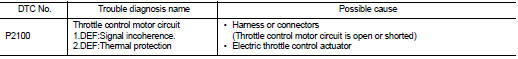

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF and wait at least 4 minutes.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK THROTTLE CONTROL MOTOR CIRCUIT FOR OPEN AND SHORT

1. Disconnect electric throttle control actuator harness connector.

2. Disconnect ECM harness connectors.

3. Check the continuity between the following terminals.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK THROTRTLE CONTROL MOTOR

Perform EC-998, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Perform EC-998, "Special Repair Requirement".

>> INSPECTION END

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK THROTTLE CONTROL MOTOR

1. Reconnect all harness connectors disconnected.

2. Check the voltage between ECM harness connectors terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Perform EC-998, "Special Repair Requirement".

>> INSPECTION END

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-882, "Work Procedure".

>> END

P2080 EGT sensor 1

P2080 EGT sensor 1

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

P2119 electric throttle control function

P2119 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 2.

N ...

Other materials:

Hazard and buzzer reminder does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...

Oil pan (upper)

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain tensioner

10. Oil pump

11. Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Oil filt ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...