Nissan Juke Service and Repair Manual : P0120 TP sensor

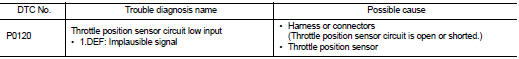

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect electric throttle control actuator harness connector.

2. Turn ignition switch ON.

3. Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK THROTTLE POSITION SENSOR

Refer to EC-910, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Perform EC-910, "Special Repair Requirement".

>> INSPECTION END

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK THROTTLE POSITION SENSOR

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Turn ignition switch ON.

4. Check the voltage between ECM harness connector terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator assembly.

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-882, "Work Procedure".

>> END

P0115 ECT sensor

P0115 ECT sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

P012A TC boost sensor

P012A TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

Compressor dose dot operate

Description

SYMPTOM

Compressor dose not operate.

Diagnosis Procedure

NOTE:

• Perform self-diagnosis with CONSULT-III before performing symptom diagnosis.

If any malfunction result or

DTC is detected, perform the corresponding diagnosis.

• Check that refrigerant is enclosed in cooler cycle n ...

Parking brake switch

Component Function Check

1.CHECK PARKING BRAKE SWITCH OPERATION

Operate the parking brake lever. Then check that the brake warning lamp in

the combination meter turns ON/

OFF correctly.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to BRC-70, "Diagno ...

Handling for Adhesive and Primer

• Never use an adhesive that is past its usable date. Shelf life of this

product is limited to six months after the

date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored

...