Nissan Juke Service and Repair Manual : P0078 EVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-585, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing (EVT) control solenoid valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between exhaust valve timing control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between EVT control solenoid valve harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVT control solenoid valve harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE

Check the exhaust valve timing control solenoid valve. Refer to EC-586, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace exhaust valve timing control solenoid valve.

Component Inspection

1.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-I

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing control solenoid valve harness connector.

3. Check resistance between exhaust valve timing control solenoid valve terminals as per the following.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace exhaust valve timing control solenoid valve. Refer to EM-67, "Exploded View".

2.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-II

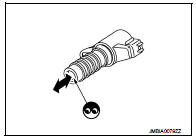

1. Remove exhaust valve timing control solenoid valve.

2. Provide 12 V DC between exhaust valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Check that the plunger moves as shown in the figure.

CAUTION:

Do not apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in exhaust valve timing control solenoid valve.

NOTE

:

Always replace O-ring when exhaust valve timing control

solenoid valve is removed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace exhaust valve timing control solenoid valve. Refer to EM-67, "Exploded View".

P0075 IVT control solenoid valve

P0075 IVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

P0102, P0103 MAF SENSOR

P0102, P0103 MAF SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

Other materials:

Forward-facing child restraint installation using LATCH

Refer to all Warnings and Cautions in the “Child safety” and “Child restraints”

sections before installing a child restraint.

Follow these steps to install a forward-facing child restraint using the LATCH

system:

1. Position the child restraint on the seat.

Always follow the child restraint m ...

P0715 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...

Cylinder head

Exploded View

1. Camshaft sprocket

2. Cylinder head suspended bracket

3. Valve lifter

4. Valve rotator

5. Valve spring retainer

6. Valve spring

7. Exhaust valve

8. Intake valve

9. Valve collet

10. Cap

11. Rear engine slinger

12. Cylinder head gasket

13. Cylinder head

14. Cam ...