Nissan Juke Service and Repair Manual : Fuel tank

Exploded View

1. Fuel filler cap

2. Grommet

3. Fuel filler tube

4. Vent hose

5. Clamp

6. Fuel filler hose

7. Clamp

8. Fuel tank

9. Fuel tank mounting band (RH)

10. Fuel tank mounting band (LH)

11. EVAP canister

12. EVAP canister hose

A. To fuel tube

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to

FL-30, "General Precautions".

REMOVAL

• Drain fuel from fuel tank if necessary. Refer to FL-33, "Removal and Installation".

• Perform work on level place.

1. Remove RH rear wheel.

2. Perform steps 2 to 7 of “REMOVAL” in “FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP

ASSEMBLY” on fuel level sensor unit, fuel filter and fuel pump assembly. Refer to FL-33, "Removal and Installation".

3. Remove sub muffler. Refer to EM-166, "Removal and Installation".

4. Remove insulator on vehicle side located above center and sub muffler.

5. Remove floor under covers (RH, LH) Refer to EXT-25, "Exploded View".

6. Move parking brake cable (1) from the lower face of fuel tank. Then remove clips for parking brake cable.

7. Disconnect fuel filler hose at fuel tank side.

1 : Filler tube

2 : Filler hose

8. Remove vent hose at RH rear wheel well side

9. Remove EVAP canister hose (1) at front side of fuel tank (2).

3. : Centralized under-floor piping

A. : quick connector

: Vehicle front

: Vehicle front

• Remove quick connector in the following procedures.

- Pinch quick connector square-part (A) with your fingers, and pull out the quick connector (1) by hand.

- If quick connector and tube on vehicle are stuck, push and pull several times until they move, and pull out.

CAUTION:

• The tube can be removed when the tabs are completely

depressed. Never twist it more than necessary.

• Never use any tools to disconnect quick connector.

• Keep the resin tube away from heat. Be especially careful when welding near the tube.

• Prevent acid liquid such as battery electrolyte, etc. from getting on the resin tube.

• Never bend or twist resin tube during installation and disconnection.

• To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic bags or something similar.

• Never insert plug, preventing damage on O-ring in quick connector.

10. Remove EVAP hose (1) in the back for fuel tank side.

: Vehicle front

: Vehicle front

11. Remove quick connectors (A) from the EVAP canister (1).

2. : EVAP canister hose

12. Disconnect EVAP hose and vent tube at the position shown in the figure.

• Instruction for quick connector of EVAP hose and vent tube, refer to the following:

Vent hose

• Remove quick connector in the following procedures.

- Pinch quick connector square-part (A) with your fingers, and pull out the quick connector (1) by hand.

- If quick connector and tube on vehicle are stuck, push and pull several times until they move, and pull out.

CAUTION:

• The tube can be removed when the tabs are completely

depressed. Never twist it more than necessary.

• Never use any tools to disconnect quick connector.

• Keep the resin tube away from heat. Be especially careful when welding near the tube.

• Prevent acid liquid such as battery electrolyte, etc. from getting on the resin tube.

• Never bend or twist resin tube during installation and disconnection.

• To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic bags or something similar.

• Never insert plug, preventing damage on O-ring in quick connector.

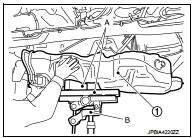

13. Support the center part of fuel tank (1) with transmission jack (B).

CAUTION:

Securely support the fuel tank with a piece of wood (A).

14. Remove fuel tank mounting bands (RH and LH).

15. Lower transmission jack carefully to remove fuel tank while holding it by hand.

CAUTION:

Fuel tank may be in an unstable condition because of the shape of fuel tank

bottom. Never rely on

jack too much. Be sure to hold tank securely.

INSTALLATION

Note the following, and install in the reverse order of removal.

Fuel Tank

1. Temporarily tighten bolts [except (4)] in numerical order as shown in the figure.

A : Under view

: Vehicle front

: Vehicle front

2. Tighten bolt (4) to specified torque, pressing fuel tank in the

direction (  ) shown in the

) shown in the

figure.

3. Tighten bolts [except (4)] to specified torque in the reverse order as shown in the figure.

Fuel Filler Hose

• Surely clamp fuel hose insert fuel filler hose to the length below.

Fuel filler hose : 35 mm (1.38 in) The other hose : 25 mm (0.98 in)

• Be sure hose clamp is not placed on swelled area of fuel filler tube.

• Install fuel filler hose to fuel tank, paying attention to install mark. Marking faces downward.

• Tighten fuel filler hose clamp so that the remaining length of screw thread becomes to the following.

Fuel filler tube side : 8 - 12 mm (0.28 - 0.43 in) Fuel tank side : 5 - 9 mm (0.25 - 0.35 in)

EVAP canister hose

1. Check connections for damage or foreign material.

2. Align the matching side connection part with the center of shaft, and insert connector straight until it clicks.

3. After connecting, pull out quick connector and centralized under floor piping by hand. Check connections are secure.

A : Pull

Inspection

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), and check connections for leakage by applying fuel pressure to fuel piping.

2. Start engine and rev it up and check there are no fuel leakage at the fuel system tube and hose connections.

Fuel level sensor unit, fuel filter and fuel pump assembly

Fuel level sensor unit, fuel filter and fuel pump assembly

Exploded View

1. Fuel tank

2. Rock ring

3.

Fuel level sensor unit, fuel filter and

fuel pump assembly

4. O-ring

: Vehicle front

: Always replace after every

disassembly.

: N·m (kg-m, ...

Evap canister

Evap canister

Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1. EVAP canister purge volume control

solenoid valve

2. Resonator

3. EVAP canister

NOTE:

Do not use soapy water or any type of solvent whil ...

Other materials:

P2118 throttle control motor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

...

Unbalance steering wheel turning force and return between

right and left

Description

Unbalance steering wheel turning force and return between right and left.

Diagnosis Procedure

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while engine is running.

Does the EPS warning lamp turn OFF?

YES >> GO TO 2.

NO >> Refer to STC ...

Charge air cooler

Exploded View

1. Air inlet tube assembly

2. Air inlet tube bracket

3. Clamp

4. Air inlet hose

5. Gasket

6. Turbocharger

7. Mounting rubber

8. Charge air cooler

9. Air inlet tube assembly

10. Air inlet tube bracket

11. Air inlet hose

12. Air inlet tube assembly

13.Turbochager b ...