Nissan Juke Service and Repair Manual : Fuel level sensor signal circuit

Component Function Check

2WD MODELS

1.CHECK COMBINATION METER OUTPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and compare the “FUEL METER” monitor value with the fuel gauge reading on the combination meter.

Does monitor value match fuel gauge reading? YES >> INSPECTION END

NO >> Replace combination meter. Refer to MWI-69, "Removal and Installation".

4WD MODELS

1.CHECK COMBINATION METER OUTPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and compare the “FUEL METER” monitor value with the fuel gauge reading on the combination meter.

Does monitor value match fuel gauge reading? YES >> INSPECTION END

NO >> Replace combination meter. Refer to MWI-69, "Removal and Installation".

Diagnosis Procedure

1.CHECK COMBINATION METER INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector and ground.

Does it match fuel gauge reading? YES >> GO TO 2.

NO >> Replace the combination meter. Refer to MWI-69, "Removal and Installation".

2.CHECK FUEL LEVEL SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and fuel level sensor unit connector.

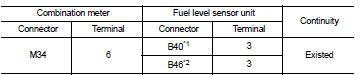

3. Check continuity between combination meter harness connector terminal and fuel level sensor unit harness connector terminal.

*1: 2WD models

*2: 4WD models

4. Check continuity between combination meter harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

Check continuity between fuel level sensor unit harness connector terminal and combination meter harness connector terminal.

*1: 2WD models

*2: 4WD models

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair harness or connector.

Component Inspection

2WD MODELS

1.REMOVE FUEL LEVEL SENSOR UNIT (MAIN)

Remove the fuel level sensor unit (main). Refer to FL-6, "2WD : Removal and Installation" (MR16DDT), FL-33, "Removal and Installation" (HR16DE), or FL-51, "Removal and Installation" (K9K).

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT (MAIN)

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is contact with stopper.

Is inspection result OK? YES >> INSPECTION END

NO >> Replace the fuel level sensor unit (main). Refer to FL-6, "2WD : Removal and Installation" (MR16DDT), FL-33, "Removal and Installation" (HR16DE), or FL-51, "Removal and Installation" (K9K).

4WD MODELS

1.REMOVE FUEL LEVEL SENSOR UNIT (MAIN)

Remove the fuel level sensor unit (main). Refer to FL-11, "4WD : Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT (MAIN)

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is contact with stopper.

Is inspection result OK? YES >> GO TO 3.

NO >> Replace fuel level sensor unit (main). Refer to FL-11, "4WD : Removal and Installation".

3.REMOVE FUEL LEVEL SENSOR UNIT (SUB)

Remove the fuel level sensor unit (sub). Refer to FL-11, "4WD : Removal and Installation".

>> GO TO 4.

4.CHECK FUEL LEVEL SENSOR UNIT (SUB)

Check the resistance between fuel level sensor unit (sub).

*: When float rod is contact with stopper.

Is inspection result OK? YES >> INSPECTION END

NO >> Replace fuel level sensor unit (sub). Refer to FL-11, "4WD : Removal and Installation".

Power supply and ground circuit

Power supply and ground circuit

Combination meter

COMBINATION METER : Diagnosis Procedure

1.CHECK FUSE

Check for blown fuses.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of ...

Oil pressure switch signal circuit

Oil pressure switch signal circuit

Component Function Check

1.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and check the “OIL W/L” monitor

value.

“OIL W/L”

Ignition switch ON : On

Engine ...

Other materials:

Diagnosis and repair work flow

Flowchart of Trouble Diagnosis

NOTE:

“DTC” includes DTC at the 1st trip.

1.OBTAIN INFORMATION ABOUT SYMPTOM

1. Refer to TM-372, "Question sheet" and interview the customer to obtain the

malfunction information (conditions

and environment when the malfunction occurred) as much as p ...

B27B0 A/C auto AMP.

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

141, "DTC Logic".

• If DTC is displayed along with DTC U1010, first perform the trouble diagnosis

for DTC U1010. HAC-142,

"DTC Log ...

B2578, B2579 In-vehicle sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

141, "DTC Logic".

• If DTC is displayed along with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to HAC-

142, &qu ...