Nissan Juke Service and Repair Manual : Fuel injector and fuel tube

Exploded View

1. Holder

2. Seal ring (white)

3. Backup ring

4. O-ring (blue)

5. Fuel injector

6. Stud bolt

7. Fuel tube assembly

8. Fuel tube insulator

9. Fuel tube protector

10. Fuel pressure sensor

11. O-ring

12. Fuel tube adaptor

13. Backup ring (white)

14. Backup ring (brown)

15. O-ring (black)

A. To fuel tube

B. Tighting must be done following the installation

procedure. Refer to EM-47

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

: Should be lubricated with oil.

: Should be lubricated with oil.

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

Removal and Installation

WARNING:

• Be sure to read EM-7, "Precaution for Handling High Pressure Fuel System" when

working on the

high pressure fuel system.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire extinguisher.

• Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

• To avoid the danger of being scalded, never drain engine coolant when engine is hot.

REMOVAL

1. Release the fuel pressure. Refer to EC-140, "Work Procedure".

2. Remove front bumper. Refer to EXT-12, "Exploded View" 3. Remove charge are cooler. Refer to EM-31, "Exploded View".

4. Remove oil level gauge. Refer to EM-40, "Exploded View".

5. Remove intake manifold. Refer to EM-28, "Exploded View".

6. Remove alternator. Refer to CHG-30, "MR16DDT : Exploded View" 7. Remove oil level gauge guide. Refer to EM-40, "Exploded View".

8. Remove fuel tube protector, and them remove fuel tube insulator.

9. Remove high pressure pump insulator. Refer to EM-43, "Exploded View".

10. Remove fuel tube. Refer to EM-43, "Exploded View".

11. Disconnect fuel pressure sensor harness connector.

12. Disconnect fuel injector harness connector.

13. Remove fuel tube.

• Loosen mounting bolts in reverse order as shown in the figure.

: Engine front

: Engine front

CAUTION:

• When removing, be careful to avoid any interference with fuel

injector.

• Use a shop cloth to absorb any fuel leakage from fuel tube.

14. Remove fuel pressure sensor and fuel tube adaptor, if necessary.

15. Remove fuel injector from cylinder head as per the following.

CAUTION:

• Be careful with remaining fuel that may go out from fuel tube.

• Be careful no to damage injector nozzles during removal.

• Never bump or drop fuel injector.

• Never disassemble fuel injector.

a. Remove injector holder.

b. Install an remover [SST: KV10119600] (A) to the injector connector side so that cutout (B) of injector remover faces the injector connector side.

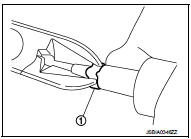

![• Hook pawl portion (B) of injector remover [SST: KV10119600]](images/books/335/2/index.19.jpg)

• Hook pawl portion (B) of injector remover [SST: KV10119600] (A) to groove portion (C) of injector

c. Press down body portion (A) of injector remover [SST: KV10119600] until it contacts cylinder head.

![d. Tighten injector remover [SST: KV10119600] clockwise and](images/books/335/2/index.26.jpg)

d. Tighten injector remover [SST: KV10119600] clockwise and remove injector from cylinder head.

e. Cut teflon seal (1) while pinching it. Be careful not to damage injector.

f. Remove insulator from mounting hole of fuel injector of cylinder head.

INSTALLATION

1. Install seal ring to fuel injector as per the following:

CAUTION:

• Handle seal ring with bare hands. Never wear gloves.

• Never apply engine oil to seal ring.

• Never clean seal ring with solvent.

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to fuel injector (1).

![b. Set seal ring (1) to injector seal drift set [SST: KV101197S0 (—)]](images/books/335/2/index.38.jpg)

b. Set seal ring (1) to injector seal drift set [SST: KV101197S0 (—)] (A).

c. Straightly insert seal ring (1), which is set in step 2, to fuel injector as shown in the figure and install.

CAUTION:

Be careful that seal ring does not exceed the groove portion

of fuel injector.

![d. Insert injector seal drift set [SST: KV101197S0 (—)] (A) to injector](images/books/335/2/index.45.jpg)

d. Insert injector seal drift set [SST: KV101197S0 (—)] (A) to injector and rotate clockwise and counterclockwise by 90° while pressing seal ring to fit it.

NOTE

:

Compress seal ring, because this operation is for rectifying

stretch of seal ring caused by installation and for preventing

sticking when inserting injector into cylinder head.

2. Install O-ring and backup ring to fuel injector. When handing new O-ring

and backup ring, paying attention

to the following caution items:

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Never clean O-ring with solvent.

• Check that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to twist or stretch O-ring. If O-ring was stretched while it was being attached, never insert it quickly into fuel tube.

• Insert new O-ring straight into fuel rail. Never decenter or twist it.

• Always install the back up ring (1) in the right direction as instructed.

3. Install fuel injector (1) to fuel rail (2) as per the following:

3 : O-ring (blue)

4 : Backup ring

a. Install fuel injector holder (5) to fuel injector.

CAUTION:

• Never reuse injector holder. Replace it with a new one.

• Be careful to keep fuel injector holder from interfering with O-ring. If interference occurs, replace O-ring.

b. Insert fuel injector into fuel rail with fuel injector holder attached.

• Insert it while matching it to the axial center.

• Insert so that protrusion (A) of fuel injector is aligned to cutout (B).

c. Check that installation is complete by checking that fuel injector does not rotate or come off.

• Check that protrusions of fuel injectors and fuel rail are aligned with cutouts of clips after installation.

4. Insert insulator into mounting hole of fuel injector of cylinder head.

5. Install fuel pressure sensor, if removed.

6. Install fuel tube adaptor, if removed.

• Install O-ring and backup ring to fuel tube adaptor. When handing new O-ring

and backup ring, paying

attention to the following caution items:

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Never clean O-ring with solvent.

• Check that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to twist or stretch O-ring. If O-ring was stretched while it was being attached, never insert it quickly into fuel tube.

• Insert new O-ring straight into fuel rail. Never decenter or twist it.

• Always install the back up ring in the right direction as instructed.

- Since the cross sections of fuel tube adapter and back up ring are tapered, be careful with the mounting direction.

7. Install fuel rail and fuel injector assembly to cylinder head.

• Tighten mounting bolts and nuts in two steps in numerical order as shown in the figure.

: Engine front

: Engine front

1st step  : 10.0 N·m (1.0 kg-m, 89

: 10.0 N·m (1.0 kg-m, 89

in-lb)

2nd step  : 20.5 N·m (2.1 kg-m, 15

: 20.5 N·m (2.1 kg-m, 15

ft-lb)

8. Connect injector harness connector.

9. Install in the reverse order of removal after this step.

Inspection

Check on Fuel Leakage 1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, check there are no fuel leakage at connection points.

NOTE

:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, check again that there are no fuel leakage at connection points.

CAUTION:

Never touch the engine immediately after stopped, as the engine becomes

extremely hot.

High pressure fuel pump and fuel hose

High pressure fuel pump and fuel hose

Exploded View

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

1. High pressure fuel pump insulator

2. High pressure fuel pump

3. O-ring

4. Valve lifter ...

Ignition coil, spark plug and rocker cover

Ignition coil, spark plug and rocker cover

Exploded View

1. Rocker cover protector

2. O-ring

3. PCV control valve

4. PCV hose

5. Clamp

6. Rocker cover gasket

7. Rocker cover

8. Clamp

9. PCV hose

10. Oil filler cap

11. Spark ...

Other materials:

Thermo control amplifier

Removal and Installation

REMOVAL

1. Remove evaporator. Refer to HA-115, "EVAPORATOR : Removal and

Installation".

2. Remove thermo control amp. from evaporator.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-ring wi ...

4WD warning lamp

Component Function Check

1.CHECK 4WD WARNING LAMP FUNCTION

1. Turn the ignition switch ON.

2. Check that 4WD warning lamp turns on.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to diagnosis procedure. Refer to DLN-80, "Diagnosis Procedure".

Diag ...

P0846 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

&g ...