Nissan Juke Service and Repair Manual : Front wiper auto stop signal circuit

Component Function Check

1.CHECK FRONT WIPER (AUTO STOP) SIGNAL

CONSULT-III DATA MONITOR

CONSULT-III DATA MONITOR

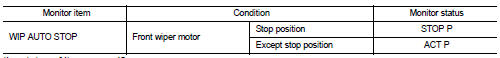

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Operate the front wiper.

3. With the front wiper operation, check the monitor status.

Is the status of item normal? YES >> Auto stop signal circuit is normal.

NO >> Refer to WW-40, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK IPDM E/R OUTPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn ignition switch ON.

4. Check voltage between front wiper motor harness connector and ground.

Is the inspection result normal? YES >> Replace front wiper motor.

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness.

Front wiper motor hi circuit

Front wiper motor hi circuit

Component Function Check

1.CHECK FRONT WIPER HI OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation ...

Front wiper motor ground circuit

Front wiper motor ground circuit

Diagnosis Procedure

1.CHECK FRONT WIPER MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Check continuity between front wiper motor harness connector ...

Other materials:

Wiring diagram

AUDIO WITHOUT NAVIGATION

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Service Notice or Precautions for Transfer

• After overhaul refill the transfer with new transfer oil.

• Check the oil level or replace the oil only with the vehicle parked on level

surface.

• During removal or installation, keep inside of transfer clear of dust or

dirt.

• Replace all tires at the same time. Always use tires of the pr ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

applications. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Modern

vehicle is equipped with many electronic control unit, and eac ...