Nissan Juke Service and Repair Manual : Clutch disc and clutch cover

Except for K9K : Exploded View

HR16DE

1. Flywheel

2. Clutch disc

3. Clutch cover

4. Input shaft

A. First step

B. Final step

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Apply lithium-based grease

: Apply lithium-based grease

including molybdenum disulphide.

MR16DDT

1. Flywheel 2. Clutch disc 3. Clutch cover 4. Input shaft

A. First step B. Final step

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Apply lithium-based grease

: Apply lithium-based grease

including molybdenum disulphide.

Except for K9K : Removal and Installation

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position

every time when removing transaxle assembly. At this timing, dust on the sliding

parts may damage

a seal of CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Installation".

• Never bring any grease to the clutch disc facing, pressure plate surface and flywheel surface.

• Never clean clutch disc using solvent.

REMOVAL

1. Remove transaxle assembly. Refer to TM-30, "Removal and Installation" (RS5F92R), or TM-84, "MR16DDT : Removal and Installation" (RS6F94R).

2. Remove clutch cover mounting bolts while holding clutch cover.

CAUTION:

Never drop clutch disc.

3. Remove clutch cover and clutch disc.

CAUTION:

Never drop clutch disc

.

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and powder arisen from abrasion.

2. Apply recommended grease to clutch disc (1) and input shaft (2) splines (A).

CAUTION:

Be sure to apply grease to the points specified. Otherwise,

noise, poor disengagement, or damage to the clutch may

result. Excessive grease may cause slip or judder. And if it

adheres to seal of CSC, it cause clutch fluid leakage. Wipe

out excess grease. Wipe out any grease oozing from the

parts

.

3. Install clutch disc, using a clutch aligner (A) [Commercial service tool].

4. Install clutch cover, and then temporarily tighten clutch cover mounting bolts.

5. Tighten clutch cover mounting bolts to the specified torque evenly in two steps in the numerical order as shown in the figure.

6. For the next step and after, install in the reverse order of removal.

Except for K9K : Inspection

NSPECTION AFTER REMOVAL

Clutch Disc

• Measure circumferential runout relative to clutch disc center spline.

If it is outside the specification, replace clutch disc.

Runout limit/diameter of the area to be measured : Refer to CL-35, "Clutch Disc".

• Measure backlash to clutch disc spline and main drive gear spline at the circumference of clutch disc. If it is outside the specification, replace clutch disc.

Maximum allowable spline backlash (at outer edge of disc) : Refer to CL-35, "Clutch Disc".

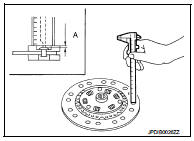

• Measure the depth “A” to clutch disc facing rivet heads, using a calipers. If it exceeds the allowable wear limit, replace clutch disc.

Facing wear limit (depth to the rivet head) “A” : Refer to CL-35, "Clutch Disc".

Clutch Cover

• Check clutch cover thrust ring for wear or breakage. If wear or breakage is

found, replace clutch cover.

NOTE

:

• Worn thrust ring will generate a beating noise when tapped at the rivet with a

hammer.

• Broken thrust ring will make a clinking sound when cover is shaken up and down.

• If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface, repair the surface with sandpaper. If surface is damaged or distorted, replace clutch cover.

INSPECTION AFTER INSTALLATION

Clutch Cover Check diaphragm spring lever claws for unevenness with the lever still on the vehicle. If they exceed the tolerance, adjust lever height, using the diaphragm adjusting wrench (A) [SST: ST20050240].

Tolerance for diaphragm spring lever unevenness : Refer to CL-36, "Clutch Cover".

K9K : Exploded View

1. Flywheel

2. Clutch disc

3. Clutch cover

4. Input shaft

A. First step B. Final step

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

K9K : Removal and Installation

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position

every time when removing transaxle assembly. At this timing, dust on the sliding

parts may damage

a seal of CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Installation".

• Never bring any grease to the clutch disc facing, pressure plate surface and flywheel surface.

• Never clean clutch disc using solvent.

REMOVAL

1. Remove transaxle assembly. Refer to TM-86, "K9K : Removal and Installation".

2. Remove clutch cover mounting bolts while holding clutch cover.

CAUTION:

Never drop clutch disc.

3. Remove clutch cover and clutch disc.

CAUTION:

Never drop clutch disc.

INSTALLATION

1. Clean clutch disc and input shaft splines to remove powder arisen from abrasion.

2. Install clutch disc, using a clutch aligner (A) [Commercial service tool].

3. Install clutch cover, and then temporarily tighten clutch cover mounting bolts.

4. Tighten clutch cover mounting bolts to the specified torque evenly in two steps in the numerical order as shown in the figure.

5. For the next step and after, install in the reverse order of removal.

K9K : Inspection

INSPECTION AFTER REMOVAL

Clutch Disc

• Measure circumferential runout relative to clutch disc center spline.

If it is outside the specification, replace clutch disc.

Runout limit/diameter of the area to be measured : Refer to CL-35, "Clutch Disc".

• Measure backlash to clutch disc spline and main drive gear spline at the circumference of clutch disc. If it is outside the specification, replace clutch disc.

Maximum allowable spline backlash (at outer edge of disc) : Refer to CL-35, "Clutch Disc".

• Measure the depth “A” to clutch disc facing rivet heads, using a calipers. If it exceeds the allowable wear limit, replace clutch disc

Facing wear limit (depth to the rivet head) “A” : Refer to CL-35, "Clutch Disc".

Clutch Cover

• Check clutch cover thrust ring for wear or breakage. If wear or breakage is

found, replace clutch cover.

NOTE

:

• Worn thrust ring will generate a beating noise when tapped at the rivet with a

hammer.

• Broken thrust ring will make a clinking sound when cover is shaken up and down.

• If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface, repair the surface with sandpaper. If surface is damaged or distorted, replace clutch cover.

INSPECTION AFTER INSTALLATION

Clutch Cover

Check diaphragm spring lever claws for unevenness with the lever

still on the vehicle. If they exceed the tolerance, adjust lever height,

using the diaphragm adjusting wrench (A) [SST: ST20050240].

Tolerance for diaphragm spring lever unevenness : Refer to CL-36, "Clutch Cover".

CSC (concentric slave cylinder)

CSC (concentric slave cylinder)

Exploded View

1. Transaxle assembly

2. CSC (Concentric Slave Cylinder)

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

CAUTION:

• Never reuse CSC (Co ...

Other materials:

P0524 engine oil pressure

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0524 is displayed with DTC P0520, P0075, or P0081, perform trouble

diagnosis for DTC P0520,

P0075, or P0081 first. Refer to EC-176, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previo ...

Seats, seat belts and Supplemental Restraint System (SRS)

1. Rear head restraints

2. Child restraint anchor points (for top tether strap child restraint)

3. Front head restraints

— Front-seat Active Head Restraints

4. Roof-mounted curtain side-impact supplemental air bags

5. Seat belts

6. Front seats

7. Supplemental front-impact air bags

...

Key ID warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...