Nissan Juke Service and Repair Manual : Camshaft

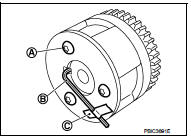

Exploded View

1. Camshaft bracket (No. 2 to 5)

2. Camshaft bracket (No. 1)

3. Camshaft sprocket (EXH)

4.Exhaust valve timing control solenoid

valve

5. O-ring

6.Camshaft sprocket (INT)

7. Plug (EXH)

8. Washer (EXH)

9.Oil filter (for exhaust valve timing control

solenoid valve)

10. Cylinder head

11.Oil filter (for intake valve timing

control solenoid valve)

12.Washer (INT)

13. Plug (INT)

14. O-ring

15. Intake valve timing control solenoid

valve

16. Bracket

17. Valve lifter

18. Camshaft (INT)

19. Camshaft (EXH)

A.Tightening must be done following the installation procedure.

Refer to EM-191

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Should be lubricated with oil.

: Should be lubricated with oil.

: Select with proper thickness.

: Select with proper thickness.

Removal and Installation

CAUTION:

The rotation direction indicated in the text indicates all directions seen from

the engine front direction.

REMOVAL

1. Hold the bottom surface of the engine with a jack to remove the right engine mount assembly and the insulator. Refer to EM-215, "Exploded View".

2. Remove rocker cover. Refer to EM-178, "Exploded View".

3. Remove camshaft position sensor from rear end of cylinder head.

CAUTION:

Handle it carefully and avoid impacts.

4. Place cylinder No. 1 at TDC of its compression stroke with the following procedure.

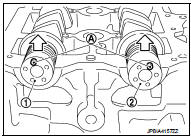

a. Rotate crankshaft pulley (2) clockwise and align TDC mark (without paint mark) (A) to timing indicator (1) on front cover.

B : White paint mark (Not use for service)

b. Check that the matching marks on each the camshaft sprockets are in the position as shown in the figure.

1. : Timing chain

2. : Camshaft sprocket (EXH)

3. : Camshaft sprocket (INT)

A : Matching mark (Peripheral groove)

B : Matching mark (Stamp)

C : Matching mark (Peripheral groove)

• If not, rotate crankshaft pulley one more turn to align matching marks to the positions in the figure.

c. Paint matching marks (A) on the timing chain links 5. Remove crankshaft pulley. Refer to EM-181, "Exploded View".

6. Remove front cover. Refer to EM-181, "Exploded View".

7. Secure the plunger of chain tensioner in the fully compressed position with the following procedure. And then, loosen the timing chain tension.

a. Fully push down the lever (B) of chain tensioner (2) from the plug hole, and then insert the stopper pin (A) into the body side hole and secure the lever at the lowest position

C : Front cover has been omitted

• The tab is released by fully pushing the lever down. As a result, the plunger (1) can be moved.

NOTE

:

Hexagonal wrench [2.5 mm (0.098 in)] is used for a stopper pin

as an example.

CAUTION:

The stopper pin must use a shape that cannot fall in the

front cover when dropping out.

b. Turn the crankshaft pulley (2) counterclockwise with the camshaft (EXH) (1) fixing. Apply the tension to the timing chain, and then push the plunger of into the inside of chain tensioner.

CAUTION:

Hold the camshaft hexagonal part (A), and then secure the

camshaft.

c. Pull out the stopper pin (A) of chain tensioner (2) side from plug hole. Lift the lever (B) up to align its hole position with the hole of the body.

D : Front cover has been omitted

• When the lever hole (C) is aligned with the body hole position, the plunger (1) is fixed.

• When the protrusion parts of the plunger ratchet and the tab face each other, both hole positions are not aligned. At that time, correctly engage them and align these hole positions by slightly moving the plunger.

d. Insert the stopper pin into the body hole through the lever hole, and then fix the lever at the upper position.

8. Remove timing chain.

9. Remove camshaft sprocket (EXH) (1).

CAUTION:

• Hold the camshaft hexagonal part (A), and then secure the

camshaft.

• Never rotate crankshaft and camshaft separately, so as not to contact valve with piston in the following steps.

NOTE:

The timing chain with the front cover installed is not disengaged from the crankshaft sprocket and it is not dropped into the front cover. Therefore, the timing chain tension holding device is not necessary.

10. Turn the camshaft sprocket (INT) to the most advanced position.

CAUTION:

Installation and removal of the camshaft sprocket (INT) must be done in the most

advanced position

for the following reasons, so check that you follow the procedure exactly.

• The sprocket (C) and vane (camshaft coupling) (B) are designed to spin and move within the range of a certain angle.

• With the engine stopped and the vane in the most retarded angle, it will not spin because it is locked to the sprocket side by the internal lock pin (A).

• If the camshaft sprocket mounting bolts are turned in the situation described above, the lock pin will become damaged and cause malfunctions because of the increased horizontal load (cutting force) on the lock pin.

• Put the camshaft sprocket (INT) in the most advance position with the following procedure

a. Remove camshaft bracket (No. 1) (1).

: Engine front

: Engine front

• Loosen the bolts in several steps, and then remove them.

b. Apply the following air pressure to the No. 1 journal oil hole (A) of camshaft (INT) (1) shown in the figure using an air gun.

Pressure : 300 kPa (3.0 bar, 3.1 kg/cm2, 44psi) or more

• Apply the air pressure into the oil hole on the second groove from the front of camshaft thrust (B).

• Proceed all the way through step “e” with the air pressure on.

• Attach the rubber nozzle (B) narrowed to the top of the air gun (A) to prevent air leakage from the oil hole. Securely apply the air pressure to the oil hole.

CAUTION:

• There are other oil holes in the side grooves. Never use

the incorrect oil holes.

• Be sure not to damage the oil path with the tip of the air gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over along with the air, and the area around the air gun should be wiped with a rag when applying air pressure. Eye protection should be worn as needed.

NOTE:

The air pressure is used to move the lock pin into the disengage position.

c. Hold the camshaft sprocket (INT) with hands, and then apply the power counterclockwise/clockwise alternatively.

• Finally rotate the sprocket of the camshaft sprocket (INT) counterclockwise

[the direction shown by the

arrow ( )].

)].

• Perform the work while applying the air pressure to the oil hole.

• If the lock pin is not released by hands, tap the camshaft sprocket (INT) lightly with a plastic hammer (A).

• If the camshaft sprocket (INT) is not rotated counterclockwise even if the above procedures are performed, check the air pressure and the oil hole position.

d. While doing the above, once you hear a click (the sound of the internal lock pin disengaging) from inside the camshaft sprocket (INT), start turning the camshaft sprocket (INT) in the counterclockwise direction in the most advanced angle position.

C : Lock pin engaged

D : Most advanced angle

• Keep the air pressure on.

• If there is no click, as soon as the vane-side (camshaft side) starts moving independently of the sprocket, the lock pin has become disengaged.

• Check that it is in the most advanced angle position by seeing if the stopper pin groove (A) and the stopper pin hole (B) are matched up as shown in the figure.

e. Complete the applying procedure of air pressure and the holding procedure of camshaft (INT).

f. Insert the stopper pin (A) into the stopper pin holes in the camshaft sprocket (INT) and lock in the most advanced angle position.

CAUTION:

No load is exerted on the stopper pin (spring reaction, etc.).

Since it comes out easily, secure it with tape (B) to prevent it from coming out.

NOTE:

The stopper pin in the figure shows one example of a hexagonal wrench for 2.5 mm (0.098 in) [length of inserted section: approximately15 mm (0.59 in)].

11. Remove the camshaft sprocket (INT) with the following procedure.

a. Keeping the camshaft hexagonal part (A) still with the wrench, loosen mounting the bolts for the camshaft sprocket (INT) (2).

1. Camshaft (INT)

CAUTION:

• Never drop stopper pin.

• Tape (C) the stopper pin (B) so it does not come out.

• Never subject it to impact by dropping.

• Never disassemble. [Never loosen the three mounting bolts (A)].

NOTE:

While removing the camshaft sprocket (INT), if you have taken out the stopper pin and the lock pin has been rejoined in the most retarded angle, do the following to restore it.

i. Install the camshaft (INT) and tighten the mounting bolts enough to prevent air from leaking out.

CAUTION:

The internal lock pin will get damaged, so keep the torque on the mounting bolts

to the minimum

required to prevent air from escapin

g.

ii. Apply the air pressure, disengage the lock pin, and turn the vane to the most advanced angle position.

iii. Insert the stopper pin.

iv. Remove camshaft sprocket (INT) from the camshaft.

12. Remove camshaft brackets (No. 2 to 5).

• Loosen bolts in several steps in the reverse of the order as shown in the figure.

A : EXH side

B : INT side

: Engine front

: Engine front

NOTE

:

The camshaft bracket (No. 1) has been already removed.

13. Remove camshaft (EXH).

14. Remove camshaft (INT).

15. Remove valve lifter.

• Identify installation positions, and store them without mixing them up.

16. Remove intake valve timing control solenoid valve (1).

17. Remove the alternator and bracket, remove the plug (2), and then remove the oil filter. Refer to CHG-26, "HR16DE : Exploded View".

18. Remove exhaust valve timing control solenoid valve.

19. Remove the plug on the exhaust valve timing control solenoid valve and the oil filter.Refer to EM-191, "Exploded View".

INSTALLATION

1. Install oil filter (1) (for intake and exhaust valve timing control solenoid valves) NOTE

:

The figure shows the intake side as an example.

2 : Washer

• The oil filter is assembled to the plug (3), and then install it to the cylinder head.

2. Install intake and exhaust valve timing controlsolenoid valves.

• Insert it straightly into the cylinder head.

• Tighten bolts after placing it completely.

3. Install valve lifter.

• If it is reused, install in its original positions.

4. Put a matching mark for positioning the camshaft (INT) and the camshaft sprocket (INT) with the following procedure.

NOTE

:

It prevents the knock pin from engaging with the incorrect pin hole after

installing the camshaft (INT) and

the camshaft sprocket (INT).

a. Put the matching marks (A) on a line extending from the knock pin position of camshaft (INT) (1) front surface.

• Put the marks on the visible position with the camshaft sprocket installed. (The figure shows an example.) b. Put the matching marks on a line extending from the knock pin hole (B) position of camshaft sprocket (INT) (2). (The figure shows an example.) • Put the marks on the visible position with it installed to the camshaft.

5. Put a matching mark for positioning the camshaft (EXH) and the camshaft sprocket (EXH) with the following procedure.

NOTE

:

It prevents the knock pin from engaging with the incorrect pin hole after

installing the camshaft (INT) and

the camshaft sprocket (EXH).

a. Put the matching marks (A) on a line extending from the knock pin position of camshaft (EXH) (1) front surface.

• Put the marks on the visible position with the camshaft sprocket installed. (The figure shows an example.) b. Put the matching marks on a line extending from the knock pin hole (B) position of camshaft sprocket (EXH) (2). (The figure shows an example.) • Put the marks on the visible position with it installed to the camshaft.

6. Install camshaft.

1 : Camshaft (EXH)

2 : Camshaft (INT)

A : Identification mark

• Distinction between camshaft (INT and EXH) is performed with the different shapes of rear end.

• Install camshafts to the cylinder head so that knock pins (A) on front end are positioned as shown in the figure.

1 : Camshaft (EXH)

2 : Camshaft (INT)

: Upper side

: Upper side

NOTE

:

Though camshaft does not stop at the portion as shown in the

figure, for the placement of cam nose, it is generally accepted

camshaft is placed for the same direction of the figure.

7. Install camshaft brackets (No. 2 to 5) aligning the identification marks on upper surface as shown in the figure.

A : EXH side

B : INT side

: Engine front

: Engine front

• Install so that identification mark can be correctly read when viewed from the INT side.

8. Tighten mounting bolts of camshaft brackets in the following steps, in numerical order as shown in the figure.

A : EXH side

B : INT side

: Engine front

: Engine front

a. Tighten No. 9 to 11 in numerical order.

: 2.0 N·m (0.2 kg-m, 1 ft-lb)

: 2.0 N·m (0.2 kg-m, 1 ft-lb)

b. Tighten No. 1 to 8 in numerical order.

2.0 N·m (0.2 kg-m, 1 ft-lb)

2.0 N·m (0.2 kg-m, 1 ft-lb)

c. Tighten all bolts in numerical order.

: 5.9 N·m (0.6 kg-m, 4 ft-lb)

: 5.9 N·m (0.6 kg-m, 4 ft-lb)

d. Tighten all bolts in numerical order.

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

9. Install the camshaft sprocket (INT and EXH) to the camshaft (INT and EXH) with the following procedure.

a. Refer to the matching mark (A) put according to step “4”.

Securely align the knock pin and the pin hole, and then install them.

NOTE

:

The figure shows the intake side as an example.

10. Tighten the camshaft sprocket mounting bolt (INT and EXH).

CAUTION:

Hold the camshaft hexagonal part (A), and then secure the

camshaft.

11. Install the camshaft (INT and EXH) to the camshaft sprocket (INT and EXH) (2 and 3) while aligning the matching mark (marked when timing chain is removed) (A) and the matching mark (stamp) (B) of camshaft sprocket (INT and EXH).

1 : Timing chain

C : Matching mark (peripheral stamp line)

• If the positions of knock pin and pin groove are not aligned, move the camshaft (EXH) slightly to correct these positions.

12. Pull out the stopper pin (A), and then apply the tension to the timing chain by rotating the crankshaft pulley clockwise slightly.

1 : Plunger

2 : Chain tensioner

B : Lever

C : Lever hole

D : Front cover has been omitted

13. Pull out the stopper pin of chain tensioner.

14. Install front cover.

15. Return the camshaft sprocket (INT) in the most retarded position with the following procedure.

a. Remove the stopper pin (A) from the camshaft sprocket (INT).

B : Tape

b. Turn the crankshaft pulley (1) slowly clockwise (A) and return the camshaft sprocket (INT) to the most retarded angle position.

• When first turning the crankshaft the camshaft sprocket (INT) will turn. Once it is turned more, and the vane (camshaft) also turns, then it has reached the most retarded angle position.

B : Stopper pin hole

C : Most advanced angle

D : Lock pin engaged

• The most retarded angle position can be checked by seeing if the stopper pin groove (A) is shifted clockwise.

• After spinning the crankshaft slightly in the counterclockwise direction, you can check the lock pin has joined by seeing if the vane (camshaft) and the sprocket move together.

16. Install the camshaft position sensor (PHASE) to the rear end of cylinder head.

• Tighten bolts with it seated completely.

17. Check and adjust valve clearance. Refer to EM-148, "Inspection and Adjustment".

18. Install in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

Oil Filter

• Check that there is no foreign material on the oil filter (1) and check

it for clogging.

• Check the oil filter for damage.

• If there is some damage, replace the oil filter, the plug, and the washer as a set.

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 5 journals

of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2. Set a dial indicator vertically to No. 3 journal.

3. Turn camshaft to one direction with hands, and measure the camshaft runout on the dial indicator. (Total indicator reading)

Standard and Limit : Refer to EM-251, "Camshaft".

4. If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1. Measure the camshaft cam height with a micrometer (A).

Standard and Limit

Intake Exhaust

: Refer to EM-251, "Camshaft".

Cam wear limit: : Refer to EM-251, "Camshaft".

2. If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance CAMSHAFT JOURNAL DIAMETER Measure the outer diameter of camshaft journal with a micrometer (A).

Standard: : Refer to EM-251, "Camshaft".

CAMSHAFT BRACKET INNER DIAMETER

• Tighten camshaft bracket bolts with the specified torque. Refer to "INSTALLATION" for the tightening procedure.

• Measure inner diameter (B) of camshaft bracket with a bore gauge (A).

Standard : Refer to EM-251, "Camshaft".

CAMSHAFT JOURNAL OIL CLEARANCE

• (Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

Standard and Limit : Refer to EM-251, "Camshaft".

• If it exceeds the limit, replace either or both camshaft and cylinder head.

NOTE

:

Camshaft brackets cannot be replaced as single parts, because they are machined

together with cylinder

head. Replace whole cylinder head assembly.

Camshaft End Play

1. Install camshaft in cylinder head. Refer to EM-191, "Removal and

Installation" for tightening procedure.

2. Install a dial indicator (A) in thrust direction on front end of camshaft.

Measure the camshaft end play on the dial indicator when camshaft is moved forward/backward (in direction to axis).

Standard and Limit : Refer to EM-251, "Camshaft".

• Measure the following parts if out of the standard.

- Dimension “A” for cylinder head No. 1 journal bearing

Standard : 4.000 - 4.030 mm (0.1574 - 0.1586 in)

- Dimension “B” for camshaft thrust

Standard : 3.877 - 3.925 mm (0.1526 - 0.1545 in)

• Refer to the standards above, and then replace camshaft and/ or cylinder head.

Camshaft Sprocket Runout 1. Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft sprocket) because it has a

different diameter

from the other four locations.

2. Measure the camshaft sprocket runout with a dial indicator.

(Total indicator reading)

Limit : 0.15 mm (0.0059 in)

• If it exceeds the limit, replace camshaft sprocket.

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

• If anything above is found, replace valve lifter. Refer to EM-251, "Camshaft".

Valve Lifter Clearance VALVE LIFTER OUTER DIAMETER

• Measure the outer diameter of valve lifter with a micrometer (A).

Standard : Refer to EM-251, "Camshaft".

VALVE LIFTER HOLE DIAMETER

Measure the diameter of valve lifter hole of cylinder head with an inside micrometer (A).

Standard : Refer to EM-251, "Camshaft".

VALVE LIFTER CLEARANCE

• (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

Standard : Refer to EM-251, "Camshaft".

• If out of the standard, referring to the each standard of valve lifter outer diameter and valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer to MA-13, "Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leakage at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE

:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after hydraulic pressure rises.

• Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

*: Transmission/transaxle fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 is detected in self-diagnostic

results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to

EC-571, "Diagnosis Procedure".

• Check when engine is cold so as to prevent burns from the splashing engine oil.

NOTE:

This section provides the inspection method of oil passage of cam sprocket on the intake side. For oil passage on the exhaust side, the inspection procedure must be changed as instructed below:

· Stap 3 : Remove exhaust valve timing control solenoid valve. Refer to EM-191, "Exploded View".

· Step 4 : Crank engine, and then check that engine oil comes out from exhaust valve timing control solenoid valve hole (A). End crank after checking.

·Step 5 Perform the following inspection if engine oil does not come out from exhaust valve timing control solenoid valve oil hole of the cylinder head.

• Remove oil filter, and then clean it. Refer to EM-236, "Inspection".

• Clean oil groove between oil strainer and exhaust valve timing control solenoid valve. Refer to LU-23, "Engine Lubrication System".

·Step 6 : Remove components between exhaust valve timing control solenoid valve and camshaft sprocket (EXH), and then check each oil groove for clogging.

1. Check engine oil level. Refer to LU-25, "Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Release the fuel pressure. Refer to EC-551, "Work Procedure".

b. Remove intake manifold. Refer to EM-163, "Exploded View".

c. Disconnect ignition coil and injector harness connectors. Refer to EM-178, "Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-191, "Exploded View".

4. Crank engine, and then check that engine oil comes out from intake valve timing control solenoid valve hole (A). End crank after checking.

1 : Plug

:Engine front

:Engine front

WARNING:

Be careful not to touch rotating parts (drive belts, idler pulley,

and crankshaft pulley, etc.).

CAUTION:

• Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil

contamination.

• Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts, engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

5. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid valve oil hole of the cylinder head.

• Remove oil filter, and then clean it. Refer to EM-236, "Inspection".

• Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-23, "Engine Lubrication System".

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT), and then check each oil groove for clogging.

• Clean oil groove if necessary. Refer to LU-23, "Engine Lubrication System".

7. After inspection, install removed parts in the reverse order

Timing chain

Timing chain

Exploded View

1. Timing chain slack guide

2. Timing chain tensioner

3. Camshaft sprocket (EXH)

4. Camshaft sprocket (INT)

5. Plug 6. Front oil seal

7. Crankshaft pulley

8. Crankshaft pull ...

Oil seal

Oil seal

Valve oil seal

VALVE OIL SEAL : Removal and Installation

REMOVAL

1. Remove camshafts. Refer to EM-191, "Exploded View".

2. Remove valve lifters. Refer to EM-191, "Exploded View" ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

C1130 engine signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent

error detection ability.

Many electronic control units are equipped onto vehicles, and ea ...