Nissan Juke Service and Repair Manual : Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-425, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect brake pedal position switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between brake pedal position switch harness connector and ground.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is the inspection result normal? YES >> GO TO 2.

NO >> Perform the trouble diagnosis for power supply circuit.

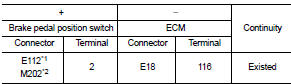

2.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between brake pedal position switch harness connector and ECM harness connector.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE PEDAL POSITION SWITCH

Check the brake pedal position switch. Refer to EC-426, "Component Inspection (Brake Pedal Position Switch)" Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD)

Component Inspection (Brake Pedal Position Switch)

1.CHECK BRAKE PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect brake pedal position harness connector.

3. Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-II

1. Adjust brake pedal position switch installation. Refer to BR-9, "Inspection and Adjustment" (LHD) or BR- 77, "Inspection and Adjustment" (RHD).

2. Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View" (LHD) or BR-88, "Exploded View" (RHD).

Refrigerant pressure sensor

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check ...

Clutch pedal position switch

Clutch pedal position switch

Component Function Check

1.CHECK FOR CLUTCH PEDAL POSITION SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result nor ...

Other materials:

B2614 ACC relay circuit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn the power supply position to ACC under the following conditions, and

wait for 2 second or more.

CVT models

- Selector lever is in the P or N position

- Do not depress brake pedal

M/T m ...

Vehicle information

BODY EXTERIOR PAINT COLOR

Body Exterior Paint Color

FOR 2WD MODELS

NOTE:

• S: Solid

• 2S: Solid + Clear

• CS: Color clear solid

• M: Metallic

• P: 2-Coat pearl

• 3P: 3-Coat pearl

• FPM: Iron oxide pearl

• RPM: Multi flex color

• TM: Micro titanium metallic

• PM: Pearl metallic

FOR ...

How to use touch screen

CAUTION

• The glass screen on the liquid crystal display may break if it is hit with

a hard or sharp object. If the glass screen breaks, do not touch it.

Doing so could result in an injury.

• To clean the display, never use a rough cloth, alcohol, benzine, thinner or any

kind of solvent or pa ...