Nissan Juke Service and Repair Manual : Brake booster

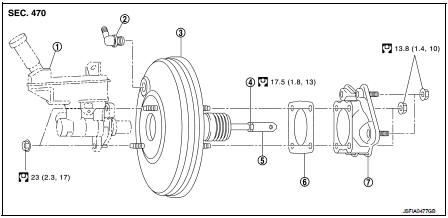

Exploded View

2WD

1. Master cylinder assembly

2. Vacuum pipe

3. Brake booster

4. Lock nut

5. Clevis

6. Gasket

7. Spacer

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

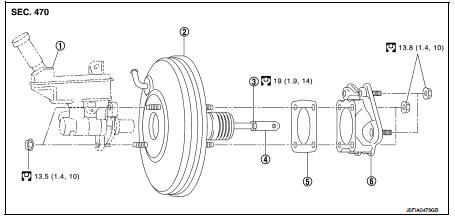

4WD

1. Master cylinder assembly

2. Brake booster

3. Lock nut

4. Clevis

5. Gasket

6. Spacer

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and installation

REMOVAL

1. Perform inspection before removal. Refer to BR-47, "Inspection and Adjustment".

2. Remove cowl top and cowl top extension. Refer to EXT-20, "Removal and Installation".

3. Remove air duct and air cleaner case.

• MR16DDT: Refer to EM-26, "Removal and Installation".

• HR16DE: Refer to EM-161, "Removal and Installation".

• K9K: Refer to EM-280, "Removal and Installation".

4. Remove brake master cylinder assembly. Refer to BR-42, "Removal and Installation".

5. Remove vacuum hose from brake booster.

• MR16DDT: Refer to BR-49, "MR16DDT : Removal and Installation".

• HR16DE: Refer to BR-50, "HR16DE : Removal and Installation".

• K9K: Refer to BR-52, "K9K : Removal and Installation".

6. Remove snap pin (1) and clevis pin (2). Refer to BR-20, "Exploded View".

7. Remove nuts on brake booster and brake pedal assembly.

CAUTION:

Hold the brake booster so as to avoid dropping out.

8. Remove brake booster and spacer.

CAUTION:

Never deform or bend the brake tubes.

NOT

E:

If removing brake booster is difficult, remove clevis from brake

booster.

9. Remove vacuum pipe from brake booster. (2WD) 10. Remove spacer from brake booster.

11. Perform inspection after removal. Refer to BR-47, "Inspection and Adjustment".

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously

damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Note the following, and install in the reverse order of removal.

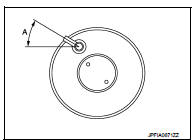

• Set vacuum pipe angle (A) as shown in the figure. (2WD)

A : 50 – 60°

• Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installation, the dash panel may damage the threads.

• Never deform or bend the brake tubes when installing the brake booster.

• Always use a gasket between the brake booster and the spacer.

• Replace the clevis pin if it is damaged. Refer to BR-22, "Inspection and Adjustment".

• Perform the air bleeding. Refer to BR-13, "Bleeding Brake System".

• Check each item of brake pedal. Adjust it if the measurement value is not the standard. Refer to BR-9, "Inspection and Adjustment".

Inspection and Adjustmen

INSPECTION BEFORE REMOVAL

Air Tight

CAUTION:

Check the air tight condition when the master cylinder and the brake booster is

installed.

1. Check the air tight use a handy vacuum pump.

At vacuum of −66.7 kPa (−500 mmHg, −19.69 inHg, −0.067 bar) : Vacuum should decrease within 3.3 kPa (24.8 mmHg, 0.98 inHg, 0.033 bar) for 15 seconds.

2. If the air tight condition cannot be maintained, perform the following operation.

a. Check the no dirt and dust are present on the brake booster and brake master cylinder mating faces.

Clean it if necessary.

b. Check the O-ring on the master cylinder. If anything is found, replace the O-ring. Refer to BR-42, "Removal and Installation".

c. Check the air tight condition again. If the condition still cannot be maintained, replace the brake booster.

INSPECTION AFTER REMOVAL

Input Rod Length Inspection 1. Loosen the lock nut (1) and adjust the input rod (2) to the specified length (A).

A : Refer to BR-70, "Brake Booster".

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the engine

stopped. Start the engine with the

brake pedal fully depressed. Check that the clearance between brake pedal and

dash lower panel decreases.

NOTE

:

A slight impact with a small click may be felt on the pedal when the brake pedal

is fully depressed. This is a

normal phenomenon due to the brake system operation.

Air Tight

1. Run the engine at idle for 1 minute to apply vacuum to the brake booster, and

stop the engine.

2. Depress the brake pedal several times at 5-second intervals until the accumulated vacuum is released to atmospheric pressure. Check that the clearance between brake pedal and dash lower panel gradually increases each time the brake pedal is depressed when performing this operation.

3. Depress the brake pedal with the engine running. Then stop the engine while holding down the brake pedal. Check that the brake pedal stroke does not change after holding down the brake pedal for 30 seconds or more.

ADJUSTMENT AFTER INSTALLATION

Perform the brake pedal adjustment after installing the brake pedal assembly. Refer to BR-9, "Inspection and Adjustment".

Brake master cyl

Brake master cyl

Exploded View

2WD

1. Reservoir cap

2. Oil strainer

3. Reservoir tank

4. Cylinder body

5. Pin

6. O-ring

7. Grommet

: Apply polyglycol ether based

lubricant.

: Apply brake fluid.

: N· ...

Vacuum lines

Vacuum lines

MR16DDT : Exploded View

1. Clamp

2. Vacuum hose A

3. Vacuum piping

4. Vacuum hose B

A. To engine side

B. Paint mark C. To brake booster

MR16DDT : Removal and Installation

REMOVAL

1. Remo ...

Other materials:

B2205 vehicle speed

Description

Vehicle speed signal is transmitted from ABS actuator and electric unit

(control unit) via CAN communication

to combination meter.

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform “Self Diagnost ...

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and “ABS actuator and electric unit (control

unit)”.

Be sure to erase the malfunction information such as DTC not only for “ABS

actuator ...

Too much power

Description

CHART 13: TOO MUCH POWER

Diagnosis Procedure

1.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT

Check ECM power supply and ground circuit. Refer to EC-885, "Diagnosis

Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness ...