Nissan Juke Service and Repair Manual : Oil pan

Exploded View

1. Baffle plate

2. Gasket

3. Oil pan

4. O-ring

5. Drain plug

6. Oil level gauge guide

7. Transaxle

8. Crankshaft position sensor (POS)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

CAUTION:

Never drain engine oil when the engine is hot to avoid the danger of being

scalded.

1. Remove engine under cover.

2. Remove RH front wheel. Refer to WT-7, "Exploded View".

3. Remove fender protector RH. Refer to EXT-22, "Exploded View".

4. Remove engine mounting bracket. Refer to EM-326, "Exploded View".

5. Remove center bearing bracket as shown.

6. Remove A/C compressor bracket mounting bolt as shown.

7. Remove oil level gauge guide.

8. Drain engine oil. Refer to LU-34, "Draining".

CAUTION:

Perform when engine is cold.

9. Remove oil pan and transaxle joint bolts.

10. Support the engine bottom of the oil pan with a transmission jack etc.

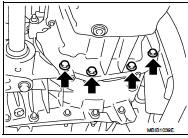

11. Remove oil pan bolt reverse order as shown.

• Insert seal cutter (special service tool) between upper oil pan and cylinder block. Slide tool by tapping on the side of the tool with a hammer.

CAUTION:

Exercise care not to damage mating surface.

12. Remove oil pan and baffle plate.

INSTALLATION

• Install in the reverse order of removal paying attention to the following.

1. Apply liquid gasket as shown.

• Use Genuine Liquid Gasket or equivalent.

2. Install baffle plate.

3. Install oil pan.

• Tighten the mounting bolts of oil pan on the clutch housing without locking.

• Tighten the bolts in the numerical order shown in the figure.

: 14 N·m (1.4 kg-m, 10 ft-lb)

: 14 N·m (1.4 kg-m, 10 ft-lb)

• Tighten the mounting bolts of oil pan on the clutch housing.

: 44 N·m (4.5 kg-m, 10 ft-lb)

: 44 N·m (4.5 kg-m, 10 ft-lb)

4. At least 30 minutes after oil pan is installed, pour engine oil.

Inspection

INSPECTION AFTER REMOVAL

Clean oil pump assembly if any object attached.

INSPECTION AFTER INSTALLATION

• Inspection the engine oil level. Refer to LU-33, "Inspection".

• Start the engine, and make sure there is no leak of engine oil. Refer to LU-33, "Inspection".

Exhaust manifold

Exhaust manifold

Exploded View

1. Exhaust gas temperature sensor 1

2. Gasket

3. Exhaust manifold

4. Exhaust gas pressure sensor 1

A. To cylinder head

: N·m (kg-m, ft-lb)

: Always replace after every

disas ...

Glow plug

Glow plug

Exploded View

1. Glow plug

Engine front

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

Remove glow plug only if necessary. If carbon adheres, it may be stuck and

broken.

1. ...

Other materials:

Intelligent Key

Replace the battery in the Intelligent Key as follows: 1. Remove the mechanical

key from the Intelligent Key.

2. Insert a small screwdriver into the slit of the corner and twist it to separate

the upper part from the lower part. Use a cloth to protect the casing.

3. Replace the battery with ...

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indication normal?

YES >> Hood switch is OK.

NO >> Go to SEC-155, "Diagnosis Procedure& ...

System (intelligent key system)

Intelligent key system : System Diagram

Intelligent key system : System Description

• The Intelligent Key system is a system that makes it possible to lock and

unlock the door locks (door lock/

unlock function) by carrying the Intelligent Key, which operates based on the

results of electron ...