Nissan Juke Service and Repair Manual : Windshield glass

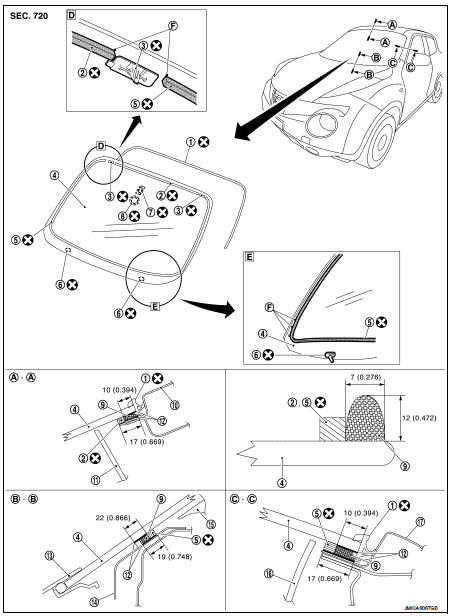

Exploded View

1. Windshield glass molding

2. Dam rubber (upper)

3. Upper clip

4. Windshield glass

5. Dam rubber (lower)

6. Lower clip

7. Mirror base

8. Rain sensor bracket

9. Adhesive

10. Roof panel

11. Headlining assembly

12. Primer

13. Cowl top cover

14. Cowl top panel

15. Instrument panel assembly

16. Front pillar finisher

17. Body side outer panel

F : Black print mark

Unit: mm (in)

: Do not reuse

: Do not reuse

Removal and Installation

REMOVAL

1. Remove front pillar garnish (LH and RH). Refer to INT-18, "FRONT PILLAR GARNISH : Removal and Installation".

2. Remove inside mirror assembly. Refer to MIR-41, "Removal and Installation".

CAUTION:

Replace inside mirror assembly after removal, when installing windshield glass.

3. Remove partially the headlining (front edge). Refer to INT-26, "Removal and Installation".

4. Remove front wiper arm (LH and RH). Refer to WW-76, "Removal and Installation".

5. Remove front fender cover (LH and RH). Refer to EXT-20, "Removal and Installation".

6. Remove cowl top cover. Refer to EXT-20, "Removal and Installation".

7. Apply protective tape around the windshield glass to protect the painted surface from damage.

8. Remove glass using piano wire or power cutting tool (A) and an inflatable pump bag (B) after removing moldings.

NOTE

:

Mark the body and the glass with matching marks if the windshield glass is

reused.

WARNING:

Always wear safety glasses and heavy gloves to help prevent injuries.

CAUTION:

• Never use a cutting knife or power cutting tool when the glass is reused.

• Be careful not to scratch the glass when removing.

• Never set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

• The dam sealant rubber should be installed in position.

• Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions provided with it.

• Open a door window while the urethane adhesive is curing. This prevents the glass from being forced out by passenger room air pressure when all door windows are closed.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive is completely cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Never let them come in contact with the skin and eyes.

• Use in an open, well ventilated location. Never breathe the vapors. They may be harmful if inhaled. Move immediately to an area with fresh air if affected by vapor inhalation.

• Driving the vehicle before the urethane adhesive is completely cured may affect the performance of the windshield in an accident.

CAUTION:

• Perform adjustment of front wiper arms stop location. Refer to WW-76,

"Adjustment".

• Never use an adhesive that is past its usable term. Shelf life of this product is limited to six months after the date of manufacture. Adhere carefully to the expiration or manufacture date printed on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Never leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for 24 hours or more or until the urethane adhesive is completely cured. Curing time varies depending on temperature and humidity. The curing time increases under lower temperature and lower humidity.

Inspection

REPAIRING WATER LEAKAGE FOR WINDSHIELD GLASS

Leakage can be repaired without removing the windshield glass.

Determine the extent of leakage if water is leaking between the urethane adhesive material and body or glass.

This can be done by applying water to the windshield area while pushing glass outward.

Apply primer (if necessary) and then urethane adhesive to the leakage point to stop the leakage.

Back door window glass

Back door window glass

Exploded View

1. Back door window glass

2. Spacer

3. Back door window glass holder

4. Back door window glass molding

5. Pivot seal

6. Adhesive

7. Primer

8. Back door outer

9. Back doo ...

Other materials:

Starting system (without intelligent key)

CVT : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

M/T : Wiring Diagram

For connector terminal arrangem ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...