Nissan Juke Service and Repair Manual : Unit removal and installation

Transaxle assembly

MR16DDT : Exploded View

1. Transaxle assembly

: Refer to "INSTALLATION" in

: Refer to "INSTALLATION" in

TM-84, "MR16DDT : Removal and Installation" for the locations and tightening

torque.

MR16DDT : Removal and Installation

CAUTION:

Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position every

time when removing transaxle assembly. At this timing, dust on the sliding parts

may damage a seal of

CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Installation".

REMOVAL

1. Disconnect battery cable from negative terminal. Refer to PG-124, "Removal and Installation".

2. Shift the shifter lever to the neutral position.

3. Remove battery. Refer to PG-124, "Removal and Installation".

4. Remove air cleaner case. Refer to EM-26, "Removal and Installation".

5. Remove air breather hose. Refer to TM-82, "MR16DDT : Removal and Installation".

6. Disconnect position switch connector. Refer to TM-77, "Removal and Installation".

7. Remove harness clip from transaxle assembly.

8. Disconnect selector cable and shifter cable from transaxle assembly. Refer to TM-78, "Removal and Installation".

9. Remove starter motor. Refer to STR-29, "MR16DDT : Removal and Installation".

10. Remove clutch tube from CSC (Concentric Slave Cylinder). Refer to CL-25, "Removal and Installation".

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never depress clutch pedal during removal procedure.

11. Remove engine under cover.

12. Remove fender protector LH. Refer to EXT-22, "Removal and Installation".

13. Disconnect ground cable.

14. Remove front suspension member. Refer to FSU-18, "Removal and Installation".

15. Remove front drive shafts. Refer to FAX-22, "LEFT SIDE : Removal and Installation" (LEFT SIDE) and FAX-24, "RIGHT SIDE : Removal and Installation" (RIGHT SIDE).

NOTE

:

Insert a suitable plug into differential side oil seal after removing front

drive shaft.

16. Set a suitable jack to transaxle assembly and then set a suitable jack to engine assembly.

CAUTION:

When setting a suitable jack, be careful so that it does not contact with the

switch.

17. Remove engine mounting insulator (LH) mounting bolts from transaxle assembly. Refer to EM-55, "2WD : Removal and Installation".

: Vehicle front

18. Remove rear engine mounting bracket and rear torque rod. Refer to EM-55, "2WD : Removal and Installation".

19. Remove transaxle assembly mounting bolts.

20. Remove transaxle assembly from the engine.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

21. Remove CSC. Refer to CL-27, "Removal and Installation".

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

• When installing transaxle assembly, never bring input shaft into contact with clutch cover.

• Tapping work for tapping bolts is not applied to new transaxle case. Do not perform tapping by other than screwing tapping bolts because tapping is formed by screwing tapping bolts into transaxle case.

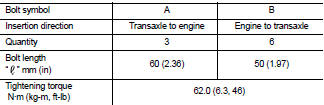

• Tighten transaxle assembly mounting bolts to the specified torque.

The figure is the view from the engine.

MR16DDT : Inspection

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-81, "Inspection".

• Check the oil leakage and the oil level. Refer to TM-75, "Inspection".

K9K : Exploded View

1. Transaxle assembly

: Refer to "INSTALLATION" in

: Refer to "INSTALLATION" in

TM-86, "K9K : Removal and Installation" for the locations and tightening torque

K9K : Removal and Installation

CAUTION:

Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position every

time when removing transaxle assembly. At this timing, dust on the sliding parts

may damage a seal of

CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Installation".

REMOVAL

1. Disconnect battery cable from negative terminal. Refer to PG-124, "Removal and Installation".

2. Shift the shifter lever to the neutral position.

3. Remove battery. Refer to PG-124, "Removal and Installation".

4. Remove air cleaner case. Refer to EM-280, "Removal and Installation".

5. Remove air breather hose. Refer to TM-83, "K9K : Removal and Installation".

6. Disconnect position switch connector. Refer to TM-77, "Removal and Installation".

7. Remove harness clip from transaxle assembly.

8. Remove crankshaft position sensor. Refer to EM-288, "Removal and Installation".

9. Disconnect selector cable and shifter cable from transaxle assembly. Refer to TM-78, "Removal and Installation".

10. Remove starter motor. Refer to EM.

11. Remove clutch tube from CSC (Concentric Slave Cylinder). Refer to CL-25, "Removal and Installation".

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never depress clutch pedal during removal procedure.

12. Remove engine under cover.

13. Remove fender protector LH. Refer to EXT-22, "Removal and Installation".

14. Disconnect ground cable.

15. Remove front drive shafts. Refer to FAX-78, "LEFT SIDE : Removal and Installation" (LEFT SIDE) and FAX-79, "RIGHT SIDE : Removal and Installation" (RIGHT SIDE).

NOTE

:

Insert a suitable plug into differential side oil seal after removing front

drive shaft.

16. Remove bracket from clutch housing.

17. Set a suitable jack to transaxle assembly and then set a suitable jack to engine assembly.

CAUTION:

When setting a suitable jack, be careful so that it does not contact with the

switch

.

18. Remove engine mounting bracket (LH) (TBD) mounting bolts from transaxle assembly. Refer to EM-326, "Removal and Installation".

: Vehicle front

: Vehicle front

19. Remove bracket stay mounting bolts and move thermo plunger unit aside not to interfere with work. Refer to CO-72, "Removal and Installation".

20. Remove transaxle assembly mounting bolts.

21. Remove transaxle assembly from the engine.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

22. Remove CSC. Refer to CL-27, "Removal and Installation".

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

• When installing transaxle assembly, never bring input shaft into contact with clutch cover.

• Tapping work for tapping bolts is not applied to new transaxle case. Do not perform tapping by other than screwing tapping bolts because tapping is formed by screwing tapping bolts into transaxle case.

• Tighten transaxle assembly mounting bolts to the specified torque.

The figure is the view from the engine.

K9K : Inspection

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-81, "Inspection".

• Check the oil leakage and the oil level. Refer to TM-75, "Inspection".

Air breather hose

Air breather hose

MR16DDT : Exploded View

1. Clip

2. Air breather hose

3. 2 way connector

MR16DDT : Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-26, "Removal and Installation& ...

Other materials:

Jump starting

To start your engine with a booster battery, the instructions and precautions

below must be followed.

WARNING

• If done incorrectly, jump starting can lead to a battery explosion, resulting

in severe injury or death.

It could also damage your vehicle.

• Explosive hydrogen gas is always prese ...

Compression pressure

Inspection

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-551, "Work Procedure".

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-178,

"Exploded View".

4. Connect engine tachometer (not required in use of CONSULT-III ...

P1574 ASCD vehicle speed sensor

Description

The ECM receives two vehicle speed sensor signals via CAN communication line.

One is sent from combination

meter, and the other is from TCM (Transmission control module). The ECM uses

these signals for ASCD

control. Refer to EC-64, "AUTOMATIC SPEED CONTROL DEVICE (ASCD) : Sys ...