Nissan Juke Service and Repair Manual : Rear disc brake

Brake pad : Exploded View

1. Sliding pin bolt

2. Cylinder body

3. Inner shim cover

4. Inner shim

5. Inner pad (with pad wear sensor)

6. Pad retainer

7. Torque member

8. Outer pad

9. Outer shim

10. Outer shim cover

1 Apply rubber grease.

1 Apply rubber grease.

2: Apply MOLYKOTE® AS880N or

2: Apply MOLYKOTE® AS880N or

silicone-based grease.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Brake pad : Removal and In

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust

collector. Never blow with

compressed air.

CAUTION:

• Never depress the brake pedal while removing the brake pads because the piston

may pop out.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Remove tires.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch.

4. Remove the brake pads, shims, shim covers and pad retainers from the torque member.

CAUTION:

• Never deform the pad retainer (2) when removing the pad

retainer from the torque member (1).

• Never damage the piston boot.

• Never drop the brake pads, shims, and the shim covers.

• Remember each position of the removed brake pads.

5. Perform inspection after removal. Refer to BR-121, "BRAKE PAD : Inspectio

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust

collector. Never blow with

compressed air.

CAUTION:

• Never depress the brake pedal while removing the brake pads or the cylinder

body because the piston

may pop out.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Install the pad retainers (1) to the torque member (2) if the pad retainers has been removed.

CAUTION:

• Securely assemble the pad retainers so that it will not be

lifted up from the torque member.

• Never deform the pad retainers.

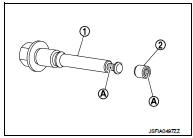

2. Apply MOLYKOTE® AS880N or silicone-based grease to the mating faces (A) between the brake pads and the shims, and install the shims to the brake pad.

CAUTION:

Always replace the shim together with the shim cover when

replacing the brake pad.

3. Install the brake pads to the torque member.

4. Install cylinder body to torque member.

CAUTION:

• Never damage the piston boot.

• When replacing brake pad with new one, check a brake fluid level in the reservoir tank because brake fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the lower sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer to BR-121, "BRAKE PAD : Inspection".

7. Install tires. Refer to WT-7, "Exploded View".

Brake pad : Inspection

INSPECTION AFTER REMOVAL

• Replace the shims and the shim covers if rust is excessively attached.

• Eliminate rust on the pad retainers and the torque member. Replace them if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-128, "BRAKE PAD : Removal and Installation".

3. Press the pistons. Refer to BR-128, "BRAKE PAD : Removal and Installation".

4. Install brake pads. Refer to BR-128, "BRAKE PAD : Removal and Installation".

5. Securely depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the

cylinder body and replace if

necessary. Refer to BR-132, "BRAKE CALIPER ASSEMBLY : Disassembly and

Assembly"

7. Burnish contact surfaces brake pads and disc rotor after refinishing or

replacing brake pads, or if a soft

pedal occurs at very low mileage. Refer to BR-86, "BRAKE PAD : Inspection and

Adjustment".

Brake caliper assembly : Exploded View

REMOVAL

1. Brake caliper assembly

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

1. Sliding pin bolt

2. Bushing

3. Cap

4. Bleeder valve

5. Cylinder body

6. Piston seal

7. Piston

8. Piston boot

9. Sliding pin boot

10. Torque member

: Apply rubber grease.

: Apply rubber grease.

: Apply brake fluid.

: Apply brake fluid.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembl

Brake caliper assembly : Removal and Installation

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust

collector. Never blow with

compressed air.

CAUTION: • Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it out immediately and wash with water if it gets on a protect surface. For brake component parts, never wash them with water.

• Never depress the brake pedal while removing the brake hose. If this is not complied with, brake fluid may splash.

• Never drop removed parts.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-80, "Draining".

4. Separate brake hose from caliper assembly. Refer to BR-101, "REAR : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pad and caliper assembly.

6. When removing disc rotor.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust

collector. Never blow with

compressed air.

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

out immediately and wash with water if it gets on a protect surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose. If this is not complied with, brake fluid may splash.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Install disc rotor.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

2. Install the brake caliper assembly to the axle housing and tighten the torque member mounting bolts to the specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake

caliper assembly mounting face, threads, mounting bolts

and washers. Wipe out any grease and moisture.

3. Install brake hose. Refer to BR-101, "REAR : Removal and Installation".

4. Perform the air bleeding. Refer to BR-81, "Bleeding Brake System".

5. Check a drag of rear disc brake. If any drag is found, refer to BR-130, "BRAKE PAD : Inspection".

6. Install tires. Refer to WT-7, "Exploded View".

7. Perform inspection after installation. Refer to BR-134, "BRAKE CALIPER ASSEMBLY : Inspection".

Brake caliper assembly : Disassembly and Assembly

DISASSEMBLY

NOTE

:

Never remove the torque member, brake pad and pad retainers when disassembling

and assembling the cylinder

body.

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member. Refer to BR-128, "BRAKE PAD : Removal and Installation".

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2. Remove sliding pin boots from torque member.

3. Remove bushing (1) from sliding pin bolt (2).

4. Place a wooden block as shown in the figure, and blow air from union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Never get fingers caught in the pistons.

5. Remove piston seal from cylinder body using seal pick tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

6. Remove bleeder valve and cap.

7. Perform inspection after disassembly. Refer to BR-126, "BRAKE CALIPER ASSEMBLY : Inspection".

ASSEMBLY

1. Install bleeder valve and cap.

2. Apply rubber grease to piston seals (1), and install them to cylinder body.

CAUTION:

Never reuse piston seals.

3. Apply rubber grease to piston boots (1). Cover the piston (2) end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.

CAUTION:

Never reuse piston boots

.

4. Apply new brake fluid to pistons (1). Push piston into cylinder body by hand and push piston boot (2) piston-side lip into the piston groove.

CAUTION:

Press the pistons evenly and vary the pressing point to prevent

cylinder inner wall from being rubbed.

5. Apply rubber grease to mating faces (A) between sliding pin bolt (1) and bushing (2), and install bushing to sliding pin.

6. Apply rubber grease to mating faces (A) between sliding pin bolt (1) and sliding pin boot (2), and install sliding pin and sliding pin boot to sliding torque member.

7. Install the cylinder body to tighten sliding pin bolts to the specified torque. Refer to BR-128, "BRAKE PAD : Exploded View".

Brake caliper assembly : Inspection

INSPECTION AFTER DISASSEMBLY

Check the following items and replace if necessary.

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline

and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage.

Pistons

Check the surface of the piston for rust, wear, cracks or damage.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing Check the sliding pins, sliding boots and bushing for rust, wear, cracks or damage.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-120, "BRAKE PAD : Removal and Installation".

3. Press the pistons. Refer to BR-120, "BRAKE PAD : Removal and Installation".

4. Install brake pads. Refer to BR-120, "BRAKE PAD : Removal and Installation".

5. Securely depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body and replace if necessary. Refer to BR-124, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surface between disc rotor and brake pads after refinishing or replacing disc rotor, or if a soft pedal occurs at very low mileage. Refer to BR-86, "DISC ROTOR : Inspection and Adjustment".

Front disc brake

Front disc brake

Brake pad : Exploded View

MR16DDT

1. Cylinder body

2. Inner shim

3. Inner pad (with pad wear sensor)

4. Pad retainer

5. Torque member

6. Outer pad

7. Outer shim

1: Apply MOLYKOTE® AS880 ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specifications

MR16DDT

HR16DE, K9K

Brake Pedal

Brake Booster

2WD

4WD

Front Disc Brake

MR16DDT

HR16DE, K9K

Rear Disc Brake

...

Other materials:

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indication normal?

YES >> Hood switch is OK.

NO >> Go to SEC-223, "Diagnosis Procedure& ...

Rear-facing child restraint installation using the seat belts

WARNING

The three-point seat belt with Automatic Locking Retractor (ALR) must be used

when installing a child restraint.

Failure to use the ALR mode will result in the child restraint not being properly

secured. The restraint could tip over or be loose and cause injury to a child in

a sudd ...

ECU diagnosis information

EPS control unit

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The output signal indicates the EPS control unit calculation data. The normal

values will be displayed

even in the event that the output circuit (harness) is open.

*1: Almost in accordance with the value of “MOTOR SIG”. ...