Nissan Juke Service and Repair Manual : P2101 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

NOTE

:

• If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis

for DTC P2100. Refer

to EC-376, "DTC Logic".

• If DTC P2101 is displayed with DTC P2119, first perform the trouble diagnosis for DTC P2119. Refer to EC-383, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 11 V when

engine is running.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 2 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check DTC.

Is DTC detected? YES >> Proceed to EC-378, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

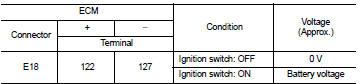

1.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL

Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect IPDM E/R harness connector.

4. Check the continuity between ECM harness connector and IPDM E/R harness connector.

5. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT

1. Check the continuity between ECM harness connector and IPDM E/R harness connector.

2. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

4.CHECK THROTTLE CONTROL MOTOR OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect electric throttle control actuator harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

5. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Remove the intake air duct. Refer to EM-26, "Exploded View".5. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY 1. Remove the intake air duct. Refer to EM-26, "Exploded View".

2. Check if foreign matter is caught between the throttle valve and the housing.

Is the inspection result normal? YES >> GO TO 6.

NO >> Remove the foreign matter and clean the electric throttle control actuator inside, then perform throttle valve closed position learning. Refer to EC-135, "Work Procedure".

2. Check if foreign matter is caught between the throttle valve and the housing.

Is the inspection result normal? YES >> GO TO 6.

NO >> Remove the foreign matter and clean the electric throttle control actuator inside, then perform throttle valve closed position learning. Refer to EC-135, "Work Procedure".

6.CHECK THROTTLE CONTROL MOTOR

Check the throttle control motor. Refer to EC-380, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

Component Inspection

1.CHECK THROTTLE CONTROL MOTOR

1. Turn ignition switch OFF.

2. Disconnect electric throttle control actuator harness connector.

3. Check the resistance between electric throttle control actuator terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

P2100, P2103 throttle control motor relay

P2100, P2103 throttle control motor relay

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. ...

P2118 throttle control motor

P2118 throttle control motor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

P1588 G sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

> ...

B1151 curtain air bag module LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Calibration of decel G sensor

Description

TCM stores calibration data (inherent characteristic value) of G sensor to

provide accurate control. Therefore,

it is required to perform calibration of G sensor after the following work is

performed.

• Removal/installation or replacement of G sensor

• Replacement of TCM

Proce ...