Nissan Juke Service and Repair Manual : P183A coupling temperature sensor right

DTC Logic

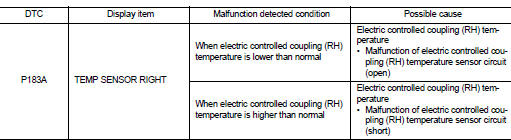

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P183A” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-65, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ELECTRIC CONTROLLED COUPLING (RH) TEMPERATURE SENSOR POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect transfer fluid temperature sensor harness connector.

3. Turn the ignition switch ON.

CAUTION:

Never start the engine.

4. Check the voltage between rear final drive assembly harness connector terminals.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ELECTRIC CONTROLLED COUPLING (RH) TEMPERATURE SENSOR CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect 4WD control module harness connector.

3. Check the continuit

4. Check the continuity between transfer fluid temperature sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

3.CHECK ELECTRIC CONTROLLED COUPLING (RH) TEMPERATURE SENSOR

Check the electric controlled coupling (RH) temperature sensor. Refer to DLN-66, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Electric controlled coupling (RH) temperature sensor is malfunctioning. Replace electric controlled coupling (RH). Refer to DLN-139, "Removal and Installation".

4.CHECK TERMINALS AND HARNESS CONNECTORS

Check the pin terminals for damage or loose connection with each harness connector.

Is the inspection result normal? YES >> Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace error-detected parts.

Component Inspection

1.CHECK ELECTRIC CONTROLLED COUPLING (RH) TEMPERATURE SENSOR

1. Turn the ignition switch OFF.

2. Disconnect rear final drive assembly harness connector.

3. Check the resistance between transfer control fluid temperature sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Electric controlled coupling (RH) temperature sensor is malfunctioning. Replace electric controlled coupling (RH). Refer to DLN-139, "Removal and Installation".

P1832 TCS operation signal

P1832 TCS operation signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC REPRODUCTION PROCEDURE

With CONSULT-III

1. Start the engine and drive at 30 km/h (19 MPH) or more.

2. Perform self-diagnosis for ...

P183B solenoid power supply

P183B solenoid power supply

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

B1153 curtain air bag module LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Removal and installation

Exhaust system

Exploded View

2WD

1. Center muffler

2. Mounting rubber

3. Spring

4. Seal bearing

5. Stud bolt

6. Three way catalyst

7. Heated oxygen sensor 2

8. Seal bearing

9. Ring gasket

10. Main muffler

A. To catalyst convertor

: N·m (kg-m, ft-lb)

: Always replace after ever ...

Rear seat belt

Exploded View

2WD models

1. Anchor bolt

2. Outer seat belt retractor RH

3. Shoulder anchor

4. Space

5. Retaining washer

6. Seat belt hook

7. Outer anchor

8. Outer seat belt retractor LH

9. Center seat belt finisher

10. Center seat belt buckle

11. RH seat belt buckle

12. Center ...