Nissan Juke Service and Repair Manual : P159B G sensor

For M/T models : DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TEST CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 11 V at idle.

> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine.

2. Drive the vehicle for at least 5 seconds at 35 km/h (22 MPH) or more.

3. Stop the vehicle and let it idle for at least 5 seconds.

NOTE

:

• Depress the brake pedal to bring the vehicle to a full stop.

• Never depress the accelerator pedal while the vehicle is stoppe

4. Repeat Step 2 and Step 3 thirteen times.

5. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-361, "FOR M/T MODELS : Diagnosis Procedure".

NO >> INSPECTION END

For M/T models : Diagnosis Pr

1.PERFORM CALIBRATION OF G SENSOR

Perform calibration of G sensor. Refer to EC-138, "Work Procedure".

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure. Refer to EC-360, "FOR M/T MODELS : DTC Logic".

Is 1st trip DTC detected? YES >> GO TO 3.

NO >> INSPECTION END

3.CHECK G SENSOR FITTING CONDITION

Check G sensor fitting condition.

Is the inspection result normal? YES >> GO TO 4.

NO >> 1. Adjust parts fitting condition.

2. Perform calibration of G sensor. Refer to EC-138, "Work Procedure".

4.CHECK G SENSOR POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect G sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between G sensor harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 7.

5.CHECK G SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between G sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK G SENSOR

Check G sensor. Refer to EC-363, "FOR M/T MODELS : Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> 1. Replace G sensor. Refer to TM-282, "Exploded View".

2. Perform calibration of G sensor. Refer to EC-138, "Work Procedure".

7.CHECK G SENSOR POWER SUPPLY CIRCUIT-II

Check the voltage between G sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 10.

8.CHECK G SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between G sensor harness connector and ECM harness connector.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

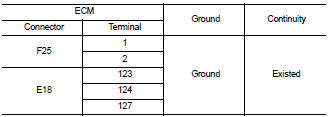

10.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connectors and each sensor harness connectors 3. Check harness connector for short to power and short to ground, between the following terminals.

*1: CVT models

*2: RHD with M/T models

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

For M/T models : Component Inspection

1.CHECK G SENSOR

With CONSULT-III

With CONSULT-III

1. Remove G sensor. Refer to TM-282, "Exploded View".

2. Reconnect all harness connectors disconnected.

3. Place the G sensor on a flat table.

4. Turn ignition switch ON.

5. Select “G SENSOR” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III to check indications according to the following conditions:

: Direction of gravitational

: Direction of gravitational

force

*: Check that voltage rises as the G sensor measurement condition changes in the order of (A), (B), and (C).

Without CONSULT-III

Without CONSULT-III

1. Remove G sensor. Refer to TM-282, "Exploded View".

2. Reconnect all harness connectors disconnected.

3. Place the G sensor on a flat table.

4. Turn ignition switch ON.5. Check the voltage between ECM harness connector terminal and ground.

5. Check the voltage between ECM harness connector terminal and ground.

: Direction of gravitational

: Direction of gravitational

force

*: Check that voltage rises as the G sensor measurement condition changes in the order of (A), (B), and (C).

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace G sensor. Refer to TM-282, "Exploded View".

Except for M/T models : Description

ECM receives a G sensor signal from TCM via CAN communication to switch combustion for the direct injection gasoline system. For the direct injection gasoline system, refer to EC-48, "DIRECT INJECTION GASOLINE SYSTEM : System Description".

Except for M/T models : DTC Logic

DTC DETECTION LOGIC

NOTE

:

• If DTC P159B is displayed with DTC UXXX, first perform the trouble diagnosis

for DTC UXXXX. Refer to EC-

108, "DTC Index".

• If DTC P159B is displayed with DTC P0607, first perform the trouble diagnosis for DTC P0607. Refer to EC- 304, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TEST CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine.

2. Drive the vehicle at least 5 seconds at 35 km/h (22 MPH) or more.

3. Stop the vehicle and let it idle at least 5 seconds.

NOTE

:

• Depress the brake pedal to bring the vehicle to a full stop.

• Never depress the accelerator pedal while the vehicle is stopped.

4. Repeat Step 2 and Step 3 thirteen times.

5. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-365, "EXCEPT FOR M/T MODELS : Diagnosis Procedure".

NO >> INSPECTION END

Except for M/T models : Diagnosis Procedure

1.CHECK DTC WITH TCM

With CONSULT-III

With CONSULT-III

Check DTC with TCM. Refer to TM-159, "CONSULT-III Function (TRANSMISSION)".

Is the inspection result normal? YES >> GO TO 2.

NO >> Perform Diagnosis Procedure corresponding to DTC indicated.

2.PERFORM CALIBRATION OF G SENSOR

Perform calibration of G sensor. Refer to EC-138, "Work Procedure".

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure. Refer to EC-364, "EXCEPT FOR M/T MODELS : DTC Logic".

Is 1st trip DTC detected? YES >> GO TO 4.

NO >> INSPECTION END

4.CHECK G SENSOR FITTING CONDITION

Check G sensor fitting condition.

Is the inspection result normal? YES >> GO TO 5.

NO >> 1. Adjust parts fitting condition.

2. Perform calibration of G sensor. Refer to TM-182, "Procedure".

5.PERFORM DIAGNOSIS PROCEDURE OF G SENSOR

Perform Diagnosis procedure of G sensor. Refer to TM-236, "Diagnosis Procedure".

Is the inspection result normal? YES >> INSPECTION END

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Except for M/T models

Except for M/T models

Except for M/T models : Description

ECM receives a G sensor signal from TCM via CAN communication to switch

combustion for the direct injection

gasoline system. For the direct injection gasoline s ...

P1650 starter motor relay 2

P1650 starter motor relay 2

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. Models with no

Intelligent Key System transmit a control signal directly to IPDM E/R. On ...

Other materials:

Fluid cooler system

Exploded View

1. Bracket

2. Bracket

3. Bracket

4. CVT fluid cooler

5. Clamp

6. CVT fluid cooler hose C

7. CVT fluid cooler hose B

8. CVT fluid cooler tube assembly

9. CVT fluid cooler hose D

10. CVT fluid cooler hose A

11. Transaxle assembly

A. CVT oil warmer

: Vehicle front

: ...

Towing your vehicle

When towing your vehicle, all State (Provincial in Canada) and local regulations

for towing must be followed. Incorrect towing equipment could damage your vehicle.

Towing instructions are available from a NISSAN dealer. Local service operators

are familiar with the applicable laws and procedur ...

P061A ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON and perform the self-diagnosis.

Is the DTC P061A displayed again?

YES >> GO TO 2.

NO &g ...