Nissan Juke Service and Repair Manual : P1220 fuel pump control module (FPCM)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is

between 12 - 15 V at idle.

• Before performing the following procedure, check that the engine coolant temperature is −10°C (14°F) or more.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 5 seconds.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-323, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK FPCM POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect FPCM harness connector.

3. Turn ignition switch ON.

4. Check the voltage between FPCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK FPCM POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between FPCM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

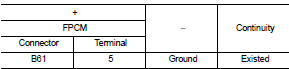

3.CHECK FPCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check the continuity between FPCM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK FPCM INPUT AND OUTPUT CIRCUITS

1. Disconnect ECM harness connector.

2. Check the continuity between FPCM harness connector and ECM harness connector

3. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK FUEL PUMP CONTROL CIRCUIT

1. Disconnect fuel level sensor unit (fuel pump) harness connector.

2. Check the continuity between FPCM harness connector and fuel level sensor unit (fuel pump) harness connector.

3. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK FPCM

Check the FPCM. Refer to EC-325, "Component Inspection (FPCM)".

Is the inspection result normal? YES >> Check intermittent incident .Refer to GI-42, "Intermittent Incident".

NO >> Replace FPCM. Refer to EC-448, "Removal and Installation".

Component Inspection (FPCM)

1.CHECK FUEL PUMP CONTROL MODULE (FPCM)

Check the voltage between FPCM terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace FPCM. Refer to EC-448, "Removal and Installation".

P1217 engine over temperature

P1217 engine over temperature

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P1217 is displayed with DTC UXXXX, first perform the trouble diagnosis

for DTC UXXXX.

• If DTC P1217 is displayed with DTC P0607, first perform the t ...

P1225 TP sensor

P1225 TP sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Removal and installation

POWER WINDOW MAIN SWITCH

Removal and Installation

REMOVAL

1. Remove power window main switch finisher. Refer to INT-13, "Removal and

Installation".

2. Remove power window main switch (1) from power window

main switch finisher (2) using flat-head screw driver (A).

: Pawl

CAUTION:

...

System

Body control system

BODY CONTROL SYSTEM : System Description

OUTLINE

• BCM (Body Control Module) controls various electrical components.It

receives the information required from

CAN communication and the signals received from each switch and sensor.

• BCM has a combination switch reading func ...

Diagnosis system (ipdm e/r) (with intelligent key system)

Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• Front wiper motor

• Parking lamp

• License p ...