Nissan Juke Service and Repair Manual : P0138 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/ F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the voltage is unusually high during the various driving condition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the minimum voltage of sensor is sufficiently low during the various driving condition such as fuel-cut.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 2 minutes.

5. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-228, "Diagnosis Procedure".

NO-1 >> With CONSULT-III: GO TO 3.

NO-2 >> Without CONSULT-III: GO TO 5.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

NOTE:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

1. Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indication is more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches 70°C (158°F).

7. Open engine hood.

8. Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULTIII.

9. Follow the instruction of CONSULT-III.

NOTE

:

It will take at most 10 minutes until “COMPLETED” is displayed.

10. Touch “SELF-DIAG RESULT”.

Which is displayed on CONSULT-III OK >> INSPECTION END

NG >> Proceed to EC-228, "Diagnosis Procedure".

CAN NOT BE DIAGNOSED>>GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B AGAIN

1. Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

2. Perform DTC confirmation procedure again.

>> GO TO 3.

5.PERFORM COMPONENT FUNCTION CHECK FOR MALFUNCTION B

Perform component function check. Refer to EC-228, "Diagnosis Procedure".

NOTE

:

Use component function check to check the overall function of the heated oxygen

sensor 2 circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-228, "Diagnosis Procedure".

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK-I

Without CONSULT-III

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK-II

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 3.

3.PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-228, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the detected malfunction (A or B). Refer to EC-226, "DTC Logic".

Which malfunction is detected? A >>GO TO 2.

B >>GO TO 7.

2.CHECK HO2S2 CONNECTOR FOR WATER

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 harness connector.

3. Check connectors for water.

Water should not exist.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

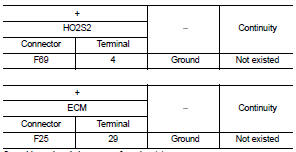

3.CHECK HO2S2 GROUND CIRCUIT

1. Disconnect ECM harness connector.

2. Check the continuity between HO2S2 harness connector and ECM harness connector.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK HO2S2 INPUT SIGNAL CIRCUIT

1. Check the continuity between HO2S2 harness connector and ECM harness connector.

2. Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK HEATED OXYGEN SENSOR 2

Check the heated oxygen sensor 2. Refer to EC-231, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> GO TO 6.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

7.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1. Clear the mixture ratio self-learning value. Refer to EC-139, "Work Procedure".

2. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0172. Refer to EC-226, "DTC Logic".

NO >> GO TO 8.

8.CHECK HO2S2 GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between HO2S2 harness connector and ECM harness connector.

5. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK HO2S2 INPUT SIGNAL CIRCUIT

1. Check the continuity between HO2S2 harness connector and ECM harness connector.

2. Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK HEATED OXYGEN SENSOR 2

Check the heated oxygen sensor 2. Refer to EC-231, "Component Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> GO TO 11.

11.REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

Component Inspection

1.INSPECTION START

Do you have CONSULT-III? Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Select “FUEL INJECTION” in “ACTIVE TEST” mode of “ENGINE” using CONSULT-III, and select “HO2S2 (B1)” as the monitor item with CONSULT-III.

7. Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ± 25%.

“HO2S2 (B1)” should be above 0.68 V at least once when the “FUEL INJECTION” is + 25%.

“HO2S2 (B1)” should be below 0.18 V at least once when the “FUEL INJECTION” is − 25%.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 6.

3.CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT-III

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK HEATED OXYGEN SENSOR 2-III

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 6.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

P0137 HO2S2

P0137 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the three way ...

P0139 HO2S2

P0139 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the three way ...

Other materials:

Front drive shaft

Exploded View

LEFT SIDE

1. Circular clip

2. Dust shield

3. Housing assembly

4. Boot band

5. Boot

6. Damper band

7. Dynamic damper

8. Circular clip

9. Joint sub-assembly

: Wheel side

: Fill NISSAN Genuine grease or

equivalent.

: Always replace after every

disassembly.

RIGHT ...

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT 1

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the voltage between the TCM harness connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK TCM POWER C ...

P0868 transmission fluid pressure

Description

The secondary pressure solenoid valve regulates the secondary pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATIO ...