Nissan Juke Service and Repair Manual : P0137 HO2S2

DTC Logic

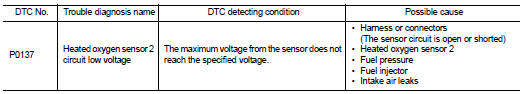

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen storage capacity of the three way catalyst 1 causes the longer switching time. To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the maximum voltage of the sensor is sufficiently high during various driving conditions such as fuel-cut.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT-III? Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 11.

2.PRECONDITIONING

• If DTC confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

• “COMPLETED” will appear on CONSULT-III screen when all tests “COND1”, “COND2” and “COND3” are completed.

TESTING CONDITION:

• For the best results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30

°C (32 to 86 °F).

• Never stop engine during this procedure. If the engine is stopped, retry procedure from PERFORM PROCEDURE FOR COND1-II.

>> GO TO 3.

3.PERFORM PROCEDURE FOR COND1-I

Start engine and warm it up to the normal operating temperature.

>> GO TO 4.

4.PERFORM PROCEDURE FOR COND1-II

Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 5.

5.PERFORM PROCEDURE FOR COND1-III

1. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

2. Let engine idle for 1 minute.

3. Select “ENGINE” using CONSULT-III.

4. Select “HO2S2 (B1) P1147” (for DTC P0137) of “HO2S2” in “DTC WORK SUPPORT” mode.

5. Touch “START”.

6. Let engine idle for at least 30 seconds.

7. Rev engine up to 2,000 rpm two or three times quickly under no load.

Is “COMPLETED” appears on CONSULT-III screen? YES >> GO TO 9.

NO >> GO TO 6.

6.PERFORM PROCEDURE FOR COND1-IV

When the following conditions are met, “TESTING” will be displayed at “COND1” on the CONSULT-III screen.

Maintain the conditions continuously until “TESTING” changes to “COMPLETED”

CAUTION:

Always drive vehicle at a safe speed.

Which displayed on CONSULT-III screen? “COND1: OUT OF CONDITION”>>GO TO 4.

“COND1: COMPLETED”, “COND2: INCOMPLETE”>>GO TO 7.

“COND1: COMPLETED”, “COND2: COMPLETED”>>GO TO 8.

7.PERFORM PROCEDURE FOR COND2

While driving, release accelerator pedal completed from the above condition (PERFORM PROCEDURE FOR COND1-III) until “INCOMPLETE” at “COND2” on CONSULT-III screen has turned to “COMPLETED” (It will take approximately 4 seconds).

CAUTION:

Always drive vehicle at a safe speed

.

Which displayed on CONSULT-III screen? “COND2: COMPLETED”, “COND3: INCOMPLETE”>>GO TO 8.

“COND2: COMPLETED”, “COND3: COMPLETED”>>GO TO 9.

8.PERFORM PROCEDURE FOR COND3-I

Stop vehicle and let it idle until “INCOMPLETE” of “COND3” on CONSULT-III screen has turned to “COMPLETED” >> GO TO 9.

9.PERFORM PROCEDURE FOR COND3-II

Touch SELF-DIAG RESULTS”.

Which displayed on CONSULT-III screen? “OK” >> INSPECTION END.

“NG” >> Go to EC-618, "Diagnosis Procedure".

“CAN NOT BE DIAGNOSED”>>GO TO 10.

10.PERFORM PROCEDURE FOR COND3-III

1. Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

2. Turn ignition switch ON and select “ENGINE” using CONSULT-III.

3. Select “COOLAN TEMP/S” in “DATA MONITOR” mode.

4. Start engine and warm it up while monitoring “COOLAN TEMP/S” indication on CONSULT-III.

5. When “COOLAN TEMP/S” indication reaches 70°C (158°F).

>> GO TO 5.

11.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-617, "Component Function Check".

NOTE

:

Use component function check the overall function of the heated oxygen sensor 2

circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Go to EC-618, "Diagnosis Procedure".

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK-I

Without CONSULT-III

Without CONSULT-III

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK-II

Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 3.

3.PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-618, "Diagnosis Procedure".

Diagnosis Procedure

1.HECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1. Clear the mixture ratio self-learning value. Refer to EC-546, "Work Procedure".

2. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0171. Refer to EC-635, "DTC Logic".

NO >> GO TO 3.

3.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between HO2S2 harness connector and ECM harness connector.

5. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between HO2S2 harness connector and ECM harness connector.

2. Check the continuity between HO2S2 harness connector ground or ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

5.CHECK HEATED OXYGEN SENSOR 2

Refer to EC-619, "Component Inspection"

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more

than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner (commercial service tool) and approved anti-seize lubricant (commercial service tool).

>> INSPECTION END

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.INSPECTION START

Do you have CONSULT-III? Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON and select “ENGINE” using CONSULT-III.

2. Select “DATA MONITOR” mode.

3. Start engine and warm it up to the normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)” as the monitor item with CONSULT-III.

8. Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)” should be above 0.68 V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)” should be below 0.36 V at least once when the “FUEL INJECTION” is −25%.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 6.

3.CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT-III

Without CONSULT-III

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK HEATED OXYGEN SENSOR 2-III

Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 6.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more

than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner (commercial service tool) and approved anti-seize lubricant (commercial service tool)

.

>> INSPECTION END

P0133 A/F sensor 1

P0133 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction of A/F sensor 1, this diagnosis measures response

time of the A/F signal computed

by ECM from the A/F sensor 1 signal. The time is compensat ...

P0138 HO2S2

P0138 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and

lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity of the three w ...

Other materials:

Precautions for Drive Shaft

• Observe the following precautions when disassembling and assembling drive

shaft.

- Never disassemble joint sub-assembly because it is non-overhaul parts.

- Perform work in a location which is as dust-free as possible.

- Clean the parts, before disassembling and assembling.

- Prevent the entr ...

B terminal circuit

Description

The “B” terminal is constantly supplied with battery power.

Diagnosis Procedure

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following

procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is ...

B20A0 cranking request circuit

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B20A0 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Perform DTC CONFIRMATION PROCEDURE for DTC P1650. Re ...