Nissan Juke Service and Repair Manual : Front drive shaft

Exploded View

LEFT SIDE

1. Circular clip

2. Dust shield

3. Housing assembly

4. Boot band

5. Boot

6. Damper band

7. Dynamic damper

8. Circular clip

9. Joint sub-assembly

: Wheel side

: Wheel side

: Fill NISSAN Genuine grease or

: Fill NISSAN Genuine grease or

equivalent.

: Always replace after every

: Always replace after every

disassembly.

RIGHT SIDE

1. Joint sub-assembly

2. Circular clip

3. Boot band

4. Boot

5. Damper band

6. Dynamic damper

7. Housing assembly

8. Dust shield

9. Support bearing

10. Snap ring

11. Plate

12. Support bearing bracket

: Wheel side

: Wheel side

: Fill NISSAN Genuine grease or

: Fill NISSAN Genuine grease or

equivalent.

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Left side : Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove wheel sensor and sensor harness. Refer to BRC-84, "FRONT WHEEL SENSOR : Exploded View" (Without ESP) or BRC-224, "FRONT WHEEL SENSOR : Exploded View" (With ESP).

3. Remove lock plate from strut assembly. Refer to FSU-10, "Removal and Installation".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-57, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (LHD) or BR-123, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (RHD).

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FAX-68, "Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FAX-68, "Removal and Installation".

7. Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub assembly from drive shaft.

NOTE

:

Use suitable puller, if wheel hub assembly and drive shaft cannot

be separated even after performing the above procedure.

8. Remove wheel hub lock nut. Refer to FAX-68, "Removal and Installation".

9. Remove transverse link from steering knuckle. Refer to FAX-68, "Removal and Installation".

10. Remove shaft assembly from wheel hub assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for joint sub-assembly, shaft and the other parts.

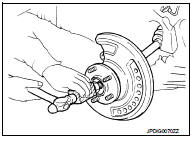

11. Use the drive shaft attachment (A) (SST: KV40107500) and a sliding hammer (B) (commercial service tool) while inserting tip of the drive shaft attachment between shaft and transaxle assembly, and then remove drive shaft from transaxle assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

• Confirm that the circular clip is attached to the drive shaft.

12. Perform inspection after installation. Refer to FAX-89, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Transaxle Side

• Always replace differential side oil seal with new one when installing drive

shaft. Refer to TM-76, "Removal

and Installation".

• Place the protector (A) (SST: KV38107900) onto transaxle assembly to prevent damage to the oil seal while inserting drive shaft.

Slide drive shaft sliding joint and tap with a hammer to install securely.

CAUTION:

Check that circular clip is completely engaged.

• Perform inspection after installation. Refer to FAX-89, "Inspection".

Wheel Hub Side

• Clean the matching surface of wheel hub lock nut and wheel hub assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

• Clean the matching surface of drive shaft and wheel hub assembly.

And then apply paste [service parts (440037S000)] to surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

Amount paste : 1.0 – 3.0 g (0.04 – 0.10 oz)

• Use the following torque range for tightening the wheel hub lock nut.

: 180 – 185 N·m (18.4 – 18.8

: 180 – 185 N·m (18.4 – 18.8

kg-m, 133 – 136 ft-lb)

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque

range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

• Never reuse wheel hub lock nut.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than torque for avoiding looseness.

• Align the matching marks that have been made during removal when reusing the disc rotor.

• When installing a cotter pin (1) and adjusting cap (2), securely bend the basal portion to prevent rattles.

CAUTION:

Never reuse cotter pin.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing wheel hub assembly and axle housing.

• Perform inspection after installation. Refer to FAX-89, "Inspection".

Right side : Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove wheel sensor and sensor harness if necessary. Refer to BRC-84, "FRONT WHEEL SENSOR : Exploded View" (Without ESP) or BRC-224, "FRONT WHEEL SENSOR : Exploded View" (With ESP).

3. Remove lock plate from strut assembly. Refer to FSU-10, "Removal and Installation".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-57, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (LHD) or BR-123, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (RHD).

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FAX-68, "Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FAX-68, "Removal and Installation".

7. Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub assembly from drive shaft.

NOTE

:

Use suitable puller, if wheel hub assembly and drive shaft cannot

be separated even after performing the above procedure.

8. Remove wheel hub lock nut. Refer to FAX-68, "Removal and Installation".

9. Remove transverse link from steering knuckle. Refer to FAX-68, "Removal and Installation".

10. Remove drive shaft from wheel hub assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for joint sub-assembly, shaft and the other parts.

11. Remove bearing housing plate bolts.

12. Remove drive shaft assembly from transaxle assembly.

CAUTION:

Never place drive shaft joint at an extreme angle when removing drive shaft.

Also be careful not to

overextend slide joint.

13. Remove support bearing bracket.

14. Perform inspection after removal. Refer to FAX-89, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Transaxle Side

• Always replace differential side oil seal with new one when installing drive

shaft. Refer to TM-76, "Removal

and Installation".

• Install support bearing bracket (1) in following procedure, - Temporarily tighten mounting bolts (A), (B), then tighten them to specified torque.

- Set plate (2) so that notch (C) becomes upper side. Temporarily tighten mounting bolts (D), (E), then tighten them to specified torque.

CAUTION:

Never reuse plate.

• Place the protector (A) (SST: KV38107900) onto transaxle assembly to prevent damage to the oil seal while inserting drive shaft.

Slide drive shaft sliding joint and tap with a hammer to install securely.

• Perform inspection after removal. Refer to FAX-89, "Inspection".

Wheel Hub Side

• Clean the matching surface of wheel hub lock nut and wheel hub assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

• Clean the matching surface of drive shaft and wheel hub assembly.

And then apply paste [service parts (440037S000)] to surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

Amount paste : 1.0 – 3.0 g (0.04 – 0.10 oz)

• Use the following torque range for tightening the wheel hub lock nut.

: 180 – 185 N·m (18.4 – 18.8

: 180 – 185 N·m (18.4 – 18.8

kg-m, 133 – 136 ft-lb)

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque

range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

• Never reuse wheel hub lock nut.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than torque for avoiding looseness.

• Align the matching marks that have been made during removal when reusing the disc rotor.

• When installing a cotter pin (1) and adjusting cap (2), securely bend the basal portion to prevent rattles.

CAUTION:

Never reuse cotter pin.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing wheel hub assembly and axle housing.

• Perform inspection after installation. Refer to FAX-89, "Inspection".

Wheel side : Disassembly and Assembly

DISASSEMBLY

1. Fix shaft with a vise.

CAUTION:

Protect shaft when fixing with a vise using aluminum or copper plates

.

2. Remove boot bands, and then remove boot from joint sub-assembly.

3. Screw drive shaft puller (A) (commercial service tool) into joint sub-assembly screw part to a length of 30 mm (1.18 in) or more.

Support drive shaft with one hand and pull out joint sub-assembly from shaft.

CAUTION:

• Align drive shaft puller and drive shaft and remove them

by pulling firmly and uniformly.

• If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace shaft and joint sub assembly as a set.

4. Remove circular clip from shaft.

5. Remove boot from shaft.

6. Perform inspection after removal. Refer to FAX-89, "Inspection".

ASSEMBLY

1. Clean the old grease on joint sub-assembly with paper waste.

2. Fill serration slot joint sub-assembly (1) with NISSAN genuine grease or equivalent until the serration slot and ball groove become full to the brim.

CAUTION:

After applying grease, use a paper waste to wipe off old

grease that has oozed out.

3. Install boot and boot bands to shaft.

CAUTION:

• Wrap serration on shaft with tape (A) to protect the boot

from damage.

• Never reuse boot and boot band.

4. Remove the tape wrapped around the serration on shaft.

5. Position the circular clip (1) on groove at the shaft edge.

CAUTION:

Never reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip.

6. Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with joint subassembly holding circular clip.

7. Install joint sub-assembly to shaft using plastic hammer.

CAUTION:

• Check circular clip is properly positioned on groove of the

joint sub-assembly.

• Confirm that joint sub-assembly is correctly engaged while rotating drive shaft.

8. Apply the specified amount of grease into the boot inside from large diameter side of boot.

Grease amount : Refer to FAX-90, "Drive Shaft".

9. Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” marks) on the shaft or joint sub-assembly, boot may

be removed. Remove all grease from the boot mounting

surface

.

10. To prevent the deformation of the boot, adjust the boot installation length (L) to the specified value shown below by inserting the suitable tool into inside of the boot from the large diameter side of the boot and discharging the inside air.

L : Refer to FAX-90, "Drive Shaft".

CAUTION:

• If the boot installation length exceeds the standard, it may cause breakage of

the boot.

• Be careful not to touch the inside of the boot with a tip of tool.

11. Secure the large and small ends of the boot with boot bands using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

• Never reuse boot band.

• Secure boot band so that dimension (A) meets the specification as shown in the figure.

A : 5.0 mm (0.197 in) or less.

12. Check that displacement does not occur when boot is rotated with the joint sub-assembly and shaft fixed.

CAUTION:

• Reinstall them using boot bands when boot installation positions become

incorrect.

• Never reuse boot band.

Transaxle side : Disassembly and Assembly

DISASSEMBLY

Left Side

1. Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. Remove wheel side boot. Refer to FAX-81, "WHEEL SIDE : Disassembly and Assembly".

3. Remove dynamic damper as per the following instructions: a. Remove damper band.

b. Remove dynamic damper from housing assembly.

4. Remove boot bands, then remove boot from housing assembly.

5. Remove circular clip from housing assembly.

6. Remove dust shield from housing assembly.

7. Perform inspection after disassembly. Refer to FAX-89, "Inspection".

Right Side

1. Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. Remove wheel side boot from joint sub-assembly. Refer to FAX-16, "WHEEL SIDE : Removal and Installation".

3. Remove dynamic damper as per the following instructions: a. Remove damper band.

b. Remove dynamic damper from housing assembly.

4. Remove boot bands, then remove boot from housing assembly.

5. Remove support bearing, follow the procedure described below.

a. Remove dust shield from housing.

b. Remove snap ring (1).

c. Press out support bearing from housing.

d. Remove dust shield from housing.

6. Perform inspection after installation. Refer to FAX-34, "Inspection".

ASSEMBLY

Left Side

1. Clean the old grease on housing assembly with paper waste.

2. Install boot and boot bands to housing assembly.

CAUTION:

• Wrap serration on housing assembly with tape (A) to protect

the boot from damage.

• Never reuse boot and boot band.

3. Remove the tape wrapped around the serration on housing assembly.

4. Apply NISSAN genuine grease (refer to parts catalog) to housing assembly.

Grease amount : Refer to FAX-90, "Drive Shaft".

5. Install boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*”

marks) on shaft or housing, boot may be removed. Remove

all grease from the surface.

6. To prevent the deformation of the boot, adjust the boot installation length to the value shown below (L) by inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging inside air.

L : Refer to FAX-90, "Drive Shaft".

CAUTION:

• If the boot installation length exceeds the standard, it may cause breakage of

the boot.

• Be careful not to touch the inside of the boot with the tip of tool.

7. Install boot bands securely.

CAUTION:

Never reuse boot bands.

For one-touch clamp band

• Install boot bands securely as shown in the figure.

For low profile type band

1. Put boot band in the groove on drive shaft boot. Then fit

pawls (  ) into holes to temporary

) into holes to temporary

installation.

NOTE

:

For the large diameter side, fit projection (A) and guide slit

(B) at first.

2. Pinch projection on the band with suitable pliers to tighten band.

3. Insert the tip of band into the lower part of pawl (marked with dotted circle) as shown in the figure.

8. Check that displacement does not occur when boot is rotated with the housing assembly fixed.

CAUTION:

• Reinstall them using boot bands when boot installation

positions become incorrect.

• Never reuse boot band.

9. Install dynamic damper, follow the procedure described below.

a. Install dynamic damper to shaft.

b. Secure dynamic damper with bands in the following specified position (A) when installing.

CAUTION:

Never reuse bands.

A : Refer to FAX-90, "Drive Shaft".

10. Install dust shield to housing assembly.

CAUTION:

Never reuse dust shield.

11. Install circular clip to housing.

CAUTION:

Never reuse circular clip

.

12. Install boot to the wheel side. Refer to FAX-81, "WHEEL SIDE : Disassembly and Assembly".

Right Side

1. Install support bearing, follow the procedure described below.

a. Install dust shield to housing.

CAUTION:

Never reuse dust shield.

b. Press support bearing (1) onto housing to using the suitable tool (A).

CAUTION:

Never reuse support bearing.

c. Install snap ring (1).

CAUTION:

Never reuse snap ring.

d. Install dust shields.

CAUTION:

Never reuse dust shields.

2. Clean the old grease on housing assembly with paper waste.

3. Install boot and boot bands to housing assembly.

CAUTION:

• Wrap serration on housing assembly with tape (A) to protect

the boot from damage.

• Never reuse boot and boot band.

4. Remove the tape wrapped around the serration on housing assembly.

5. Apply NISSAN genuine grease (refer to parts catalog) to housing assembly.

Grease amount : Refer to FAX-35, "Drive Shaft".

6. Install boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*”

marks) on shaft or housing, boot may be removed. Remove

all grease from the surface.

7. To prevent the deformation of the boot, adjust the boot installation length to the value shown below (L) by inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging inside air.

L : Refer to FAX-35, "Drive Shaft".

CAUTION:

• If the boot installation length exceeds the standard, it may cause breakage of

the boot.

• Be careful not to touch the inside of the boot with the tip of tool.

8. Install boot bands securely.

CAUTION:

Never reuse boot bands.

a. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary

) into holes to temporary

installation.

NOTE

:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert the tip of band into the lower part of pawl (marked with dotted circle) as shown in the figure.

9. Check that displacement does not occur when boot is rotated with the housing assembly fixed.

CAUTION:

• If displacement occurs, reinstall band.

• Never reuse boot band.

10. Install dynamic damper, follow the procedure described below.

a. Install dynamic damper to shaft.

b. Secure dynamic damper with bands in the following specified position (A) when installing.

CAUTION:

Never reuse bands.

A : Refer to FAX-35, "Drive Shaft"

11. Install boot to the wheel side. Refer to FAX-26, "WHEEL SIDE : Disassembly and Assembly".

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

• Move joint up/down, left/right, and in the axial directions. Check for motion that is not smooth and for significant looseness.

• Check boot for cracks, damage, and leakage of grease.

• Check the support bearing bracket for cracks, deformation and other damage.

INSPECTION AFTER DISASSEMBLY

Check the following items, and replace the part if necessary.

Dynamic Damper

Check damper for cracks or wear.

Joint Sub-Assembly

Check the following:

• Joint sub-assembly for rough rotation and excessive axial looseness.

• The inside of the joint sub-assembly for entry of foreign material.

• Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components.

Housing assembly

• Replace housing assembly if there is scratching or wear of housing assembly

roller contact surface.

• Check shaft for runout, cracks, or other damage.

Support Bearing (Right Side) Check bearing rolls freely and is free from noise, cracks, pitting or wear. Replace support bearing if there are any non-standard conditions.

Support Bearing Bracket (Right Side) Check for support bearing bracket, cracks, or damage. Replace support bearing bracket if there are any nonstandard conditions.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-84, "FRONT WHEEL SENSOR : Exploded View" (Without ESP) or BRC-224, "FRONT WHEEL SENSOR : Exploded View" (With ESP).

2. Check the wheel alignment. Refer to FSU-7, "Inspection".

Front drive shaft boot

Front drive shaft boot

Exploded View

1. Circular clip

2. Dust shield

3. Housing assembly

4. Boot band

5. Boot

6. Damper band

7. Dynamic damper

8. Circular clip

9. Joint sub-assembly

: Wheel side

: Fill NI ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

Drive Shaft

*: For measuring position, refer to FAX-81, "WHEEL SIDE : Disassembly and

Assembly" (Wheel side), FAX-

84, "TRANSAXLE SIDE : Disassembly and Assembly& ...

Other materials:

B1150 curtain air bag module LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Power supply and ground circuit

Navi control unit

NAVI CONTROL UNIT : Diagnosis Procedure

1.CHECK FUSE

Check for blown fuses.

Is inspection result OK?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between NAVI control ...

System

Interior room lamp control system

INTERIOR ROOM LAMP CONTROL SYSTEM : System Diagram

INTERIOR ROOM LAMP CONTROL SYSTEM : System Description

OUTLINE

• Interior room lamps* are controlled by interior room lamp timer control

function of BCM.

*: Map lamp (when map lamp switch is in DOOR positio ...