Nissan Juke Service and Repair Manual : Fluid cooler system

Exploded View

1. Copper washer

2. CVT fluid cooler tube

3. Hose clamp

4. Fluid cooler hose A

5. Fluid cooler tube

6. Fluid cooler hose B

7. Fluid cooler hose C

8. Transaxle assembly

9. Fluid cooler hose D

10. Fluid cooler hose E

11. Fluid cooler hose F

12. Bypass valve

13. Fluid cooler

14. Air guide

15. Bracket A

16. Bracket B

A. To radiator

: Vehicle side

: Vehicle side

Removal and Installation

REMOVAL

1. Remove engine under cover.

2. Remove front bumper assembly. Refer to EXT-13, "Removal and Installation".

3. Remove air guide from fluid cooler.

4. Remove fluid cooler hose E and fluid cooler hose F.

5. Remove fluid cooler.

6. Remove air duct (inlet). Refer to EM-26, "Removal and Installation".

7. Remove fluid cooler hose C and fluid cooler hose D.

8. Remove bypass valve from bracket B.

9. Remove fluid cooler hose A and fluid cooler hose B.

10. Remove fluid cooler tube.

11. Remove bracket A and bracket B.

12. Remove CVT fluid cooler tube from transaxle assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never reuse copper washer.

• When installing CVT fluid cooler tube (1) to transaxle assembly: - Contact CVT fluid cooler tube a boss portion (A) of the transaxle case.

- Tighten the bolt of CVT fluid cooler tube without moving the CVT fluid cooler tube

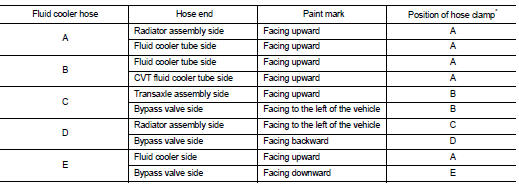

• Refer to the followings when installing fluid cooler hose.

*: Refer to the illustrations for the specific position each hose clamp tab.

- The illustrations indicate the view from the hose ends.

F : Vehicle upper

F : Vehicle upper

G : Vehicle front

G : Vehicle front

- When installing hose clamps center line of each hose clamp tab should be positioned as shown in the figure.

- Insert fluid cooler hose according to dimension (L) described below.

- Set hose clamps (1) at the both ends of fluid cooler hose (2) with dimension (A) from the hose edge.

- Hose clamp should not interfere with the bulge of fluid cooler tube.

Inspection

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and CVT fluid level. Refer to TM-184, "Inspection".

Water hose

Water hose

Exploded View

1. Hose clamp

2. Water hose

A. Water outlet

B. Oil warm

Removal and Installation

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could oc ...

Unit removal and installation

Unit removal and installation

Transaxle assembly

Exploded View

1. CVT fluid level gauge

2. CVT fluid charging pipe

3. O-ring

4. Transaxle assembly

5. Air breather hose

A. For tightening torque, refer to TM-301, "R ...

Other materials:

Back door opener actuator

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “TRUNK/BACK DOOR” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Back door o ...

Compressor dose dot operate

Description

SYMPTOM

Compressor dose not operate.

Diagnosis Procedure

NOTE:

• Perform self-diagnosis with CONSULT-III before performing symptom diagnosis.

If any malfunction result or

DTC is detected, perform the corresponding diagnosis.

• Check that refrigerant is enclosed in cooler cycle n ...

ANTI-HIJACK function does not operate

Diagnosis Procedure

1.CHECK “DOOR LOCK–UNLOCK SET” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK-UNLOCK SET” in “WORK SUPPORT” mode.

3. Check “DOOR LOCK-UNLOCK SET” in “WORK SUPPORT”

Refer to DLK-501, "DOOR LOCK : CONSULT-III Function (BCM ...