Nissan Juke Service and Repair Manual : Fillet molding

Exploded View

1. Grommet

2. Clip

3. Clip

4. Front fillet molding

5. Rear fillet molding

: Pawl

: Pawl

: Do not reuse

: Do not reuse

Front fillet molding

FRONT FILLET MOLDING : Removal and Installation

REMOVAL

1. Remove front fillet molding fixing clips.

2. Remove front fillet molding front side fixing pawls.

: Pawl

: Pawl

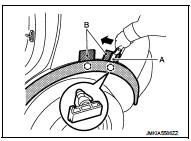

3. Using remover tool (A), disengage the clips from front fillet molding by starting from front side.

: Clip

: Clip

CAUTION:

• Apply a protective tape (B) on the body to protect the

painted surface from damage.

• Never pull fillet molding strongly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Always replace fillet molding fixing clips.

• When installing front fillet molding, check that blind clips and pawls are securely fitted in panel holes on body, and then press them in.

Rear fillet molding

REAR FILLET MOLDING : Removal and Installation

REMOVAL

1. Remove filet molding fixing clip from end of sill cover.

2. Remove rear fillet molding rear side fixing pawls.

: Pawl

: Pawl

CAUTION:

Never pull the rear fillet molding strongly.

3. Using remover tool (A), disengage the clips from rear fillet molding by starting from rear side.

: Clip

: Clip

CAUTION:

• Apply a protective tape (B) on the body to protect the

painted surface from damage.

• Never pull the rear fillet molding strongly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Always replace fillet molding fixing clips.

• When installing rear fillet molding, check that blind clips and pawls are securely fitted in panel holes on body, and then press them in.

Floor side fairing

Floor side fairing

Exploded View

1. Push spring nut

2. Floor under cover RH

3. Floor under cover LH

Removal and Installation

REMOVAL

FLOOR UNDER COVER

Remove floor under cover mounting nut and push spring nut ...

Roof side molding

Roof side molding

Exploded View

1. Roof side molding

2. Roof side molding clip

3. Double-sided tape [t: 2.5 mm (0.098 in)]

4. Body side outer panel

5. Roof panel

: Vehicle front

: Do not reuse

Removal and ...

Other materials:

Brake piping

Front : Exploded View

WITHOUT ESP

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock plate

8. Brake hose

9. Union bolt

10. Copper washer

A. To rear brake tube

: N·m (kg-m, ft-lb)

...

Precaution for Harness Repair

• Solder the repair part, and wrap it with tape. [Twisted wire fray

must be 110 mm (4.33 in) or less.]

• Never bypass the repair point with wire. (If it is bypassed, the turnout

point cannot be separated and the twisted wire characteristics

are lost.)

...

P159A, P159C, P159D G sensor

For M/T models : DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. T ...