Nissan Juke Service and Repair Manual : Diagnosis system (IPDM E/R)

With intelligent key

WITH INTELLIGENT KEY : Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• Front wiper motor

• Parking lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

CAUTION:

Wiper arm interferes with food when wiper is operated while wiper arm is in the

raised position.

Always perform auto active test without setting wiper arm in the raised position. Always pour water on front windshield glass in advance to auto active test so that damage on front windshield glass surface is prevented.

1. Turn the ignition switch OFF.

2. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the ignition switch OFF.

CAUTION:

Close passenger door.

3. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test starts.

CAUTION:

Engine starts when ignition switch is turned ON while brake pedal is depressed.

4. Oil pressure warning lamp starts blinking when the auto active test starts*. (only for K9K engine models)

*: Except for K9K engine models, oil pressure warning lamp turn ON when auto active test start.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test mode has to be cancelled halfway through test, turn the

ignition switch OFF.

• When auto active test is not activated, door switch may be the cause. Check door switch. Refer to DLK-87, "Component Function Check" (with super lock) or DLK-258, "Component Function Check" (without super lock).

Inspection in Auto Active Test Mode

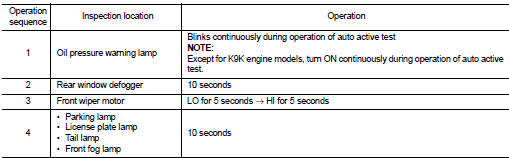

When auto active test mode is actuated, the following operation sequence is repeated 3 times.

Concept of auto active test

*: Only for models with MR16DDT engine

• IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communication.

Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

WITH INTELLIGENT KEY : CONSULT-III Function (IPDM E/R)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-25, "DTC Index".

DATA MONITOR

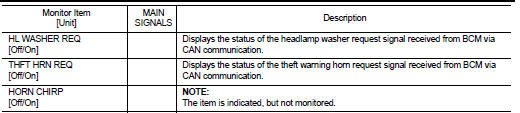

Monitor item

ACTIVE TEST

Test item

Without intelligent key

WITHOUT INTELLIGENT KEY : Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• Front wiper motor

• Parking lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

CAUTION:

Wiper arm interferes with food when wiper is operated while wiper arm is in the

raised position.

Always perform auto active test without setting wiper arm in the raised position. Always pour water on front windshield glass in advance to auto active test so that damage on front windshield glass surface is prevented.

1. Turn the ignition switch OFF.

2. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the ignition switch OFF.

CAUTION:

Close passenger door.

3. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test starts.

CAUTION:

Engine starts when ignition switch is turned ON while brake pedal is depressed.

4. Oil pressure warning lamp starts blinking when the auto active test starts*. (only for K9K engine models)

*: Except for K9K engine models, oil pressure warning lamp turn ON when auto active test start.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE

:

• When auto active test mode has to be cancelled halfway through test, turn the

ignition switch OFF.

• When auto active test is not activated, door switch may be the cause. Check door switch. Refer to DLK-397, "Component Function Check" (with super lock) or DLK-522, "Component Function Check" (without super lock).

Inspection in Auto Active Test Mode When auto active test mode is actuated, the following operation sequence is repeated 3 times.

Concept of auto active test

*: Only for models with MR16DDT engine

• IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communication.

Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

WITHOUT INTELLIGENT KEY : CONSULT-III Function (IPDM E/R)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-55, "DTC Index".

DATA MONITOR

Monitor item

ACTIVE TEST

Test item

Diagnosis system (bcm) (without intelligent key system)

Diagnosis system (bcm) (without intelligent key system)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perfo ...

Ecu diagnosis information

Ecu diagnosis information

BCM, IPDM E/R

List of ECU Reference

...

Other materials:

P1553 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following before conducting

the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. ...

Evap canister

2WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1.EVAP canister purge volume control

solenoid valve

2. EVAP canister

3. EAVP line

4. Fuel line

NOTE:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

2WD : Removal and Installation

REMOV ...

B2621 inside antenna

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INSIDE ANT DIAGNOSIS” in “WORK SUPPORT” mode.

3. Perform inside key antenna (“INSIDE ANT DIAGNOSIS”) on “WORK SUPPORT” of

“INTELL ...