Nissan Juke Service and Repair Manual : Component parts

CVT control system : Component Parts Location

1. Multi display unit (MDU)* Refer to DMS-3, "Component Parts Location".

2. Combination meter 3. Manual mode indicator (On the combination meter) 4. Shift position indicator (On the combination meter) 5. Malfunction indicator lamp (MIL) (On the combination meter) 6. ABS actuator and electric unit (control unit) Refer to BRC-97, "Component Parts Location".

7. ECM Refer to EC-25, "ENGINE CONTROL SYSTEM : Component Parts Location".

8. IPDM E/R Refer to PCS-5, "Component Parts Location" (With Intelligent Key system), PCS-37, "Component Parts Location" (Without Intelligent Key system).

9. BCM

Refer to BCS-6, "BODY CONTROL

SYSTEM : Component Parts Location"

(With Intelligent Key system), BCS-96,

"BODY CONTROL SYSTEM : Component

Parts Location" (Without Intelligent

Key system)

10. Stop lamp switch

11. Transmission range switch

12. Primary speed sensor

13. CVT unit connector

14. Control valve assembly

15. Output speed sensor

16. Secondary speed sensor

17. TCM

18. S mode switch

19. G sensor

A. Brake pedal, upper

B. Transaxle assembly

C. Engine room

D. CVT shift selector assembly

E. Driver seat (LHD) or passenger seat

(RHD), under

Transaxle assembly

*: With Nissan Dynamic Control System

NOTE

:

The following components are included in control valve assembly (13).

• CVT fluid temperature sensor

• Secondary pressure sensor

• ROM assembly

• Line pressure solenoid valve

• Low brake solenoid valve

• High clutch & reverse brake solenoid valve

• Torque converter clutch solenoid valve

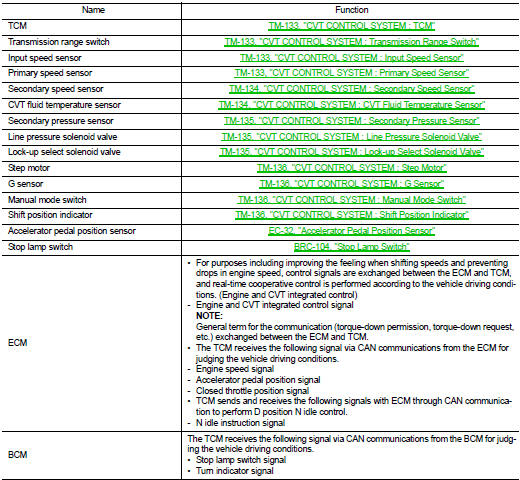

CVT control system : Component Description

*: With Nissan Dynamic Control System

CVT control system : TCM

• The vehicle driving status is judged based on the signals from the sensors, switches, and other control units, and the optimal transaxle control is performed.

• For TCM control items, refer to TM-144, "CVT CONTROL SYSTEM : System Description".

CVT control system : Transmission Range Switch

• The transmission range switch is installed to upper part of transaxle case.

• The transmission range switch detects the selector lever position.

CVT control system : Input Speed Sensor

• The input speed sensor is installed to transaxle assembly.

• The input speed sensor detects input shaft speed. TCM evaluates input speed the from the input shaft revolution.

• The input speed sensor generates the ON-OFF pulse (short waveform) in proportion to the rotating body speed which is “The higher the rotating body speed is, the faster the change cycle is”. The TCM judges the rotating speed from the changing cycle of this pulse signal.

CVT control systemM : Primary Speed Sensor

• The primary speed sensor is installed to side cover of transaxle.

• The primary speed sensor detects primary pulley speed.

• The primary speed sensor generates the ON-OFF pulse (short waveform) in proportion to the rotating body speed which is “The higher the rotating body speed is, the faster the change cycle is”. The TCM judges the rotating speed from the changing cycle of this pulse signal.

CVT control system : Secondary Speed Sensor

• The secondary speed sensor is installed to side cover of transaxle.

• The secondary speed sensor detects secondary pulley speed.

• The secondary speed sensor generates the ON-OFF pulse (short waveform) in proportion to the rotating body speed which is “The higher the rotating body speed is, the faster the change cycle is”. The TCM judges the rotating speed from the changing cycle of this pulse signal.

CVT control system : CVT Fluid Temperature Sensor

• The CVT fluid temperature sensor is installed to control valve.

• The CVT fluid temperature sensor detects CVT fluid temperature in oil pan.

• The fluid temperature sensor uses a thermistor, and changes the signal voltage by converting changes in the CVT fluid temperature to a resistance value. TCM evaluates the CVT fluid temperature from the signal voltage value.

CVT control system : Secondary Pressure Senso

• The secondary pressure sensor is installed to control valve.

• The secondary pressure sensor detects the pressure applied to the secondary pulley.

• When pressure is applied to the ceramic device in the secondary pressure sensor, the ceramic device is deformed, resulting in voltage change. TCM evaluates the secondary pressure from its voltage change. Voltage is increased along with pressure increase.

CVT control system : Line Pressure Solenoid Valve

• The line pressure solenoid valve is installed to control valve.

• The line pressure solenoid valve controls the pressure regulator valve. For information about the pressure regulator valve, refer to TM-141, "TRANSAXLE : Component Description".

• The line pressure solenoid valve uses the linear solenoid valve [N/H (normal high) type].

NOTE

:

• The principle of the linear solenoid valve utilizes the fact that the force

pressing on the valve spool installed

inside the coil increases nearly in proportion to the current. This allows it to

produce a fluid pressure that is

proportional to this pressing force.

• The N/H (normal high) produces hydraulic control when the coil is not energized.

CVT control system : Lock-up Select Solenoid Valve

• The lock-up select solenoid valve is installed to control valve.

• The lock-up select solenoid valve controls the select switch valve that switches the oil pressure applied to the lock-up clutch, forward clutch or reverse clutch.

• The lock-up select solenoid valve utilizes an ON-OFF solenoid valve.

NOTE

:

• The only operations of the valve spool installed inside the coil are pressing

or not pressing the ball which

seals the hydraulic supply section into the seat. This A/T uses N/L (normal low)

type.

• When voltage is not applied to the coil, the force of the pilot pressure presses the ball against the seat, stopping the pilot pressure at that point.

• When voltage is applied to the coil, the valve is pulled in the direction of the coil, disengaging the hydraulic seal which the ball creates. This supplies pilot pressure to the operating locations.

CVT control system : Step Motor

The step motor changes the step with turning 4 coils ON/OFF according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

CVT control system : G Sensor

• G sensor is installed to floor under instrument lower cover.

• G sensor detects front/rear G and inclination applied to the vehicle.

• G sensor converts front/rear G and inclination applied to the vehicle to voltage signal. TCM evaluates front/ rear G and inclination angle of the vehicle from the voltage signal.

CVT control system : Manual Mode Switch

Manual mode switch is installed in shift CVT shift selector. The manual mode switch sends shift up and shift down switch signals to TCM.

TCM sends the switch signals to combination meter via CAN communication line. Then manual mode switch position is indicated on the shift position indicator.

CVT control system : Shift Position Indicator

TCM transmits shift position signal to combination meter via CAN communication. The actual shift position is displayed on combination meter according to the signal.

Shift lock system : Component Parts Location

1. Shift lock release button

2. Park position switch

3. Shift lock solenoid

4. Stop lamp switch

A: CVT shift selector assembly B: Brake pedal, upper

Shift lock system : Component Description

Structure and operation

Structure and operation

Transaxle : Cross-Sectional View

1. Converter housing

2. Driven sprocket

3. Chain

4. Reverse brake

5. Oil pump

6. Forward clutch

7. Planetary carrier

8. Primary pulley

9. Sun gear

10 ...

Other materials:

B2622 inside antenna

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INSIDE ANT DIAGNOSIS” in “WORK SUPPORT” mode.

3. Perform inside key antenna (“INSIDE ANT DIAGNOSIS”) on “WORK SUPPORT” of

“INTELL ...

Turbocharger (If Equipped)

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean supply

of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

• Always use the recommended oil. Follow ...

P17Ba primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. S ...