Nissan Juke Service and Repair Manual : Chassis maintenance

Headlamp aiming adjustment (halogen type - LHD)

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE - LHD) : Description

PREPARATION BEFORE ADJUSTING

NOTE

:

• For details, refer to the regulations in your own country.

• Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been replaced.

Before performing aiming adjustment, check the following.

• Adjust the tire pressure to the specification.

• Fill with fuel, engine coolant and each oil.

• Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the luggage room.)

NOTE

:

Do not remove the temporary tire, jack and on-vehicle tool.

• Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

• Ride alone on the driver seat.

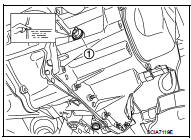

AIMING ADJUSTMENT SCREW

A. Headlamp RH (INSIDE/OUTSIDE)

adjustment screw

B. Headlamp RH (UP/DOWN)

adjustment screw

C. Headlamp LH (INSIDE/OUTSIDE)

adjustment screw

D. Headlamp LH (UP/DOWN)

adjustment screw

: Vehicle center

: Vehicle center

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE - LHD) : Aiming Adjustment Procedure

1. Place the screen.

NOTE

:

• Stop the vehicle at the perpendicular angle to the wall.

• Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (LO).

NOTE

:

Block light from the headlamp that is not being adjusted with a thick fabric or

another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so that it is within the aiming adjustment area.

Low beam distribution on the screen

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp

H. Horizontal center line of headlamp

L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)

Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10 m (32.8 ft)

Headlamp aiming adjustment (halogen type - RHD)

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE - RHD) : Description

PREPARATION BEFORE ADJUSTING

NOTE

:

• For details, refer to the regulations in your own country.

• Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been replaced.

Before performing aiming adjustment, check the following.

• Adjust the tire pressure to the specification.

• Fill with fuel, engine coolant and each oil.

• Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the luggage room.)

NOTE

:

Do not remove the temporary tire, jack and on-vehicle tool.

• Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

• Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

A. Headlamp RH (INSIDE/OUTSIDE)

adjustment screw

B. Headlamp RH (UP/DOWN)

adjustment screw

C. Headlamp LH (INSIDE/OUTSIDE)

adjustment screw

D. Headlamp LH (UP/DOWN)

adjustment screw

: Vehicle center

: Vehicle center

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE - RHD) : Aiming Adjustment Procedure

1. Place the screen.

NOTE

:

• Stop the vehicle at the perpendicular angle to the wall.

• Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (LO).

NOTE

:

Block light from the headlamp that is not being adjusted with a thick fabric or

another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so that it is within the aiming adjustment area.

Low beam distribution on the screen

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp

H. Horizontal center line of headlamp

L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)

Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10 m (32.8 ft)

Exhaust system

EXHAUST SYSTEM : Inspection

Check exhaust pipes, muffler, and mounting for improper attachment, leakage, cracks, damage or deterioration.

• If anything is found, repair or replace damaged parts.

CVT fluid (RE0F10B)

CVT FLUID (RE0F10B) : Inspection

CHECKING CVT FLUID

The fluid level should be checked with the fluid warmed up to 50 to 80°C (122 to 176°F). The fluid level check procedure is as follows: 1. Check for fluid leakage.

2. With the engine warmed up, drive the vehicle in an urban area.

When ambient temperature is 20°C (68°F), it takes about 10 minutes for the CVT fluid to warm up to 50 to 80°C (122 to 176°F).

3. Park the vehicle on a level surface.

4. Apply parking brake firmly.

5. With engine at idle, while depressing brake pedal, move shift selector throughout the entire shift range.

6. Pull out the CVT fluid level gauge from the CVT fluid charging pipe after pressing the tab on the CVT fluid level gauge to release the lock.

7. Wipe fluid off the CVT fluid level gauge. Insert the CVT fluid level gauge rotating 180° from the originally installed position, then securely push the CVT fluid level gauge until it meets the top end of the CVT fluid charging pipe.

CAUTION:

When wiping away the CVT fluid level gauge, always use

lint-free paper, not a cloth rag.

8. Place the selector lever in “P” or “N” and check that the fluid level is within the specified range.

CAUTION:

When reinstalling CVT fluid level gauge, insert it into the

CVT fluid charging pipe and rotate it to the original installation

position until securely locked.

CVT FLUID CONDITION

Check CVT fluid condition.

• If CVT fluid is very dark or smells burned, check operation of CVT.

Flush cooling system after repair of CVT.

• If CVT fluid contains frictional material (clutches, brakes, etc.), replace radiator and flush cooler line using cleaning solvent and compressed air after repair of CVT. Refer to TM-297, "Exploded View".

CVT FLUID (RE0F10B) : Changing

CAUTION:

Replace drain plug gasket with new ones at the final stage of the operation when

installing.

1. Remove drain plug from oil pan.

2. Remove drain plug gasket from drain plug.

3. Install drain plug gasket to drain plug.

CAUTION:

Never reuse drain plug gasket.

4. Install drain plug to oil pan.

Drain plug – tightening torque : Refer to TM-283, "Exploded View".

5. Fill CVT fluid from CVT fluid charging pipe to the specified level.

CVT fluid : Refer to TM-308, "General Specifica- Fluid capacity tion".

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Never mix with other fluid.

• Using CVT fluid other than Genuine NISSAN CVT Fluid NS-2 will deteriorate in driveability and CVT durability, and may damage the CVT, which is not covered by the warranty.

• When filling CVT fluid, take care not to scatter heat generating parts such as exhaust.

• Sufficiently shake the container of CVT fluid before using.

• Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid.

6. With the engine warmed up, drive the vehicle in an urban area.

NOTE

:

When ambient temperature is 20°C (68°F), it takes about 10 minutes for the CVT

fluid to warm up to 50 to

80°C (122 to 176°F).

7. Check CVT fluid level and condition.

8. Repeat steps 1 to 5 if CVT fluid has been contaminated.

CVT fluid (RE0F11A)

CVT FLUID (RE0F11A) : Inspection

FLUID LEAKAGE

• Check transaxle surrounding area (oil seal and plug etc.)for fluid leakage.

• If anything is found, repair or replace damaged parts and adjust CVT fluid level. Refer to TM-379, "Adjustment".

Gear oil (RS5F92R)

GEAR OIL (RS5F92R) : Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

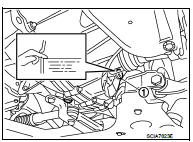

OIL LEVEL

1. Remove filler plug (1) and gasket from transaxle case.

2. Check the oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

3. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-33, "Exploded View".

GEAR OIL (RS5F92R) : Draining

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and gasket, using a socket [Commercial service tool] and then drain gear oil.

3. Set a gasket on drain plug and install it to clutch housing, using a socket [Commercial service tool].

CAUTION:

Never reuse gasket.

4. Tighten drain plug to the specified torque. Refer to TM-33, "Exploded View".

GEAR OIL (RS5F92R) : Refilling

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at filler plug mounting hole as shown in the figure.

Oil grade and viscosity : Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to TM-63, "General Specifications".

3. After refilling gear oil, check the oil level. Refer to MA-47, "GEAR OIL (RS5F92R) : Inspection".

4. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

5. Tighten filler plug to the specified torque. Refer to TM-33, "Exploded View".

Gear oil (RS6F94R)

GEAR OIL (RS6F94R) : Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

1. Remove filler plug (1) and gasket from transaxle case.

2. Check the oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

3. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-88, "Exploded View".

GEAR OIL (RS6F94R) : Draining

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and gasket, using a socket [Commercial service tool] and then drain gear oil.

3. Set a gasket on drain plug and install it to clutch housing, using a socket [Commercial service tool].

CAUTION:

Never reuse gasket.

4. Tighten drain plug to the specified torque. Refer to TM-88, "Exploded View".

GEAR OIL (RS6F94R) : Refilling

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at filler plug mounting hole as shown in the figure.

Oil grade and viscosity : Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to TM-123, "General Specifications".

3. After refilling gear oil, check the oil level. Refer to MA-48, "GEAR OIL (RS6F94R) : Inspection".

4. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

5. Tighten filler plug to the specified torque. Refer to TM-88, "Exploded View".

Clutch fluid (RS5F92R)

CLUTCH FLUID (RS5F92R) : Inspection

FLUID LEAKAGE

• Check clutch line for cracks, deterioration or other damage. Replace any damaged parts.

• Check for fluid leakage by fully depressing clutch pedal while engine is running.

CAUTION:

If leakage occurs around joints, reinstall the joints or, if necessary, replace

damaged parts.

FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified range (MAX – MIN lines).

• Visually check for any clutch fluid leakage around the reservoir tank.

• Check the clutch system for any leakage if the fluid level is extremely low (lower than MIN)

Clutch fluid (RS6F94R)

CLUTCH FLUID (RS6F94R) : Inspection

FLUID LEAKAGE

• Check clutch line for cracks, deterioration or other damage. Replace any damaged parts.

• Check for fluid leakage by fully depressing clutch pedal while engine is running.

CAUTION:

If leakage occurs around joints, reinstall the joints or, if necessary, replace

damaged parts.

FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified range (MAX – MIN lines).

• Visually check for any clutch fluid leakage around the reservoir tank.

• Check the clutch system for any leakage if the fluid level is extremely low (lower than MIN).

Transfer fluid

TRANSFER FLUID : Inspection

OIL LEAKAGE

Check transfer surrounding area (oil seal, drain plug, filler plug, and transfer case etc.) for oil leakage.

OIL LEVEL

1. Remove filler plug (1) and gasket. Then check that oil is filled up from mounting hole for the filler plug.

: Vehicle front

: Vehicle front

CAUTION:

Never start engine while checking oil level.

2. Before installing filler plug, set a new gasket. Install filler plug on transfer and tighten to the specified torque. Refer to DLN-113, "Exploded View".

CAUTION:

Never reuse gasket.

TRANSFER FLUID : Draining

1. Run the vehicle to warm up the transfer unit sufficiently.

2. Stop the engine and remove the drain plug (1) and gascket to drain the transfer oil.

3. Before installing drain plug, set a new gasket. Install drain plug on the transfer and tighten to the specified torque. Refer to DLN- 113, "Exploded View".

: Vehicle front

: Vehicle front

CAUTION:

Never reuse gasket.

TRANSFER FLUID : Refilling

1. Remove filler plug (1) and gasket. Then fill oil up to mounting hole for the filler plug.

: Vehicle front

: Vehicle front

Oil and viscosity : Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to DLN-117, "General Specifications".

CAUTION:

Carefully fill the oil. (Fill up for approximately 3 minutes.)

2. Leave the vehicle for 3 minutes, and check the oil level again.

3. Before installing filler plug, set a new gasket. Install filler plug on transfer and tighten to the specified torque. Refer to DLN-113, "Exploded View".

CAUTION:

Never reuse gasket.

Rear propeller shaft

REAR PROPELLER SHAFT : Inspection

APPEARANCE AND NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1. With a dial indicator, measure propeller shaft runout at runout measuring points by rotating final drive companion flange with hands.

Propeller shaft runout : Refer to DLN-125, "Propeller Shaft Runout".

• Propeller shaft runout measuring point (Point “

”)

: Front

: Front

Dimension A: 542 mm (21.34 in) B: 516.5 mm (20.33 in)

2. If runout still exceeds specifications, separate propeller shaft at final drive companion flange or transfer companion flange; then change the phase between companion flange and propeller shaft by the one bolt hole at a time and install propeller shaft.

3. Check runout again. If runout still exceeds specifications, replace propeller shaft assembly.

4. Check the vibration by driving vehicle.

Rear differential gear oil

REAR DIFFERENTIAL GEAR OIL : Inspection

OIL LEAKAGE

Check rear final drive surrounding area (oil seal, drain plug, filler plug, and carrier case, etc.) for oil leakage.

OIL LEVEL

1. Remove filler plug (1) and check oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

2. Set a new gasket on filler plug and install it on final drive assembly.

Refer to DLN-151, "Exploded View".

CAUTION:

Never reuse gasket.

REAR DIFFERENTIAL GEAR OIL : Draining

1. Stop engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a new gasket on drain plug and install it to final drive assembly and tighten to the specified torque. Refer to DLN-151, "Exploded View".

CAUTION:

Never reuse gasket.

REAR DIFFERENTIAL GEAR OIL : Refilling

1. Remove filler plug (1). Fill with new gear oil until oil level reaches the specified level near filler plug mounting hole.

Oil grade and viscosity : Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to DLN-167, "General Specification".

2. After refilling oil, check oil level. Set a new gasket to filler plug, then install it to final drive assembly. Refer to DLN-151, "Exploded View".

CAUTION:

Never reuse gasket

Wheels (bonding weight type)

WHEELS (BONDING WEIGHT TYPE) : Adjustment

BALANCING WHEELS (ALUMINUM WHEEL)

Preparation Before Adjustment Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road wheel.

Wheel Balance Adjustment • The details of the adjustment procedure are different for each model of wheel balancer. Therefore, refer to each instruction manual.

• If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting, select and adjust a drive-in weight mode suitable for aluminum wheels.

1. Set road wheel on tire balance machine using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer unbalance value by 5/3 to determine balance weight that should be used. Select the outer balance weight with a value closest to the calculated value above and install to the designated outer position of, or at the designated angle in relation to the road wheel.

CAUTION:

• Never install the inner balance weight before installing the outer balance

weight.

• Before installing the balance weight, always to clean the mating surface of the road wheel.

a. Indicated unbalance value × 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz) × 5/3 = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz) balance

weight (closer to calculated balance weight value)

NOTE

:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

b. Installed balance weight in the position.

• When installing balance weight (1) to road wheels, set it into the grooved area (A) on the inner wall of the road wheel as shown in the figure so that the balance weight center (B) is aligned with the tire balance machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN balance weights.

• Balance weights are non-reusable; always replace with new ones.

• Never install three or more sheets of balance weight

.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in the figure.

CAUTION:

Never install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Never install three or more balance weight.

5. Start the tire balance machine. Check that the inner and outer residual unbalance value is within the allowable unbalance value.

CAUTION:

If either residual unbalance value exceeds limit, repeat installation

procedures.

Allowable unbalance value Dynamic (At flange) : Refer to WT-9, "Road Wheel".

Static (At flange) : Refer to WT-9, "Road Wheel".

BALANCING WHEELS (STEEL WHEEL)

Preparation Before Adjustment Remove balance weight from the road wheel.

Wheel Balance Adjustment • The details of the adjustment procedure are different for each model of wheel balancer. Therefore, refer to each instruction manual.

• If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting, select and adjust a drive-in weight mode suitable for steel wheels.

1. Set road wheel to wheel balancer, and then start wheel balancer.

2. Install balance weight to road wheel according to the unbalance and position (angle) displayed on wheel balancer.

CAUTION:

• Always use genuine NISSAN balance weights.

• Balance weights are non-reusable; always replace with new ones.

• Always use a plastic hammer when attaching the weight.

• Never install three or more balance weights on one side.

3. Start the tire balance machine. Check that the inner and outer residual unbalance value is within the allowable unbalance value.

CAUTION:

If either residual unbalance value exceeds limit, repeat installation

procedures.

Allowable unbalance value Dynamic (At flange) : Refer to WT-9, "Road Wheel".

Static (At flange) : Refer to WT-9, "Road Wheel".

Brake fluid level and leaks

BRAKE FLUID LEVEL AND LEAKS : Inspection

• If fluid level is extremely low, check brake system for leaks.

Brake lines and cables

BRAKE LINES AND CABLES : Inspection

• Check brake fluid lines and parking brake cables for improper attachment, leaks, chafing, abrasions, deterioration, etc.

Brake fluid

BRAKE FLUID : Changing

1. Drain brake fluid from each bleed valve.

2. Refill until new brake fluid comes out from each bleed valve.

Use same procedure as in bleeding hydraulic system to refill brake fluid.

Refer to BR-13, "Bleeding Brake System" (LHD models), BR-81, "Bleeding Brake System" (RHD models).

• Refill with recommended brake fluid.

Refer to MA-13, "Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

Disc brake

DISC BRAKE : Inspection

DISC ROTOR

Check condition, wear, and damage.

CALIPER

• Check for leakage

BRAKE PAD

• Check for wear or damage.

DISC BRAKE : Front Disc Brake

MR16DDT

HR16DE, K9K

DISC BRAKE : Rear Disc Brake

Steering gear and linkage

STEERING GEAR AND LINKAGE : Inspection

STEERING GEAR

• Check gear housing and boots for looseness, damage and grease leakage.

• Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

Axle and suspension parts

AXLE AND SUSPENSION PARTS : Inspection

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Check wheel bearings for smooth operation.

• Check axle and suspension nuts and bolts for looseness.

• Check strut (shock absorber) for oil leakage or other damage.

• Check suspension ball joint for grease leakage and ball joint dust cover for cracks or other damage

Drive shaft

DRIVE SHAFT : Inspection

Check boot and drive shaft for cracks, wear, damage and grease leakage.

Engine maintenance (K9K)

Engine maintenance (K9K)

Drive belt

DRIVE BELT : Checking Drive Belts

WARNING:

Be sure to perform when the engine is stopped.

1. Inspect belts for cracks, fraying, wear and oil. If necessary,

replace.

2. Evaluate manu ...

Body maintenance

Body maintenance

Locks, hinges and hood latch

LOCKS, HINGES AND HOOD LATCH : Lubr

Seat belt, buckles, retractors, anchors and adjusters

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

For fron ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain the malfunction information (conditions and

environment when the malfunction

occurred) as much as possible when the customer brings the vehicle in.

>> GO TO 2.

...

Commercial Service Tools

HFC-134a (R-134a) Service Tool and Equipment

• Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with

CFC-12 (R-12) refrigerant and/

or its lubricant.

• Separate and non-interchangeable service equipment must be used for handling

each type of refrigerant/

lubricant.

• R ...

System

Engine control system : System Diagram

Engine control system : System Description

ECM performs various controls such as fuel injection control and ignition

timing control.

MULTIPORT FUEL INJECTION SYSTEM

Multiport fuel injection system : System Diagram

Multiport fuel injection system : ...