Nissan Juke Service and Repair Manual : Camshaft valve clearance

Valve Clearance

CHECKING AND ADJUSTING THE VALVE CLEARANCE

1. Install the tappet.

2. Install the camshaft.

3. Install the camshaft brackets.

: 11 N·m (1.1 kg-m, 8 ft-lb)

: 11 N·m (1.1 kg-m, 8 ft-lb)

4. Place the valves of the cylinder concerned at the “end of exhaust - beginning of inlet” position and check the clearance (X).

NOTE

:

Dimension (Y) corresponds to the tappet thickness sizes (there

are 25 sizes at the service parts).

5. Compare the values recorded with the values specified, then replace the tappets which are not within tolerance.

Clearance, when the engine cold: Intake : 0.125 - 0.25 mm (0.0049 - 0.0098 in) Exhaust : 0.325 - 0.45 mm (0.0128 - 0.0177 in)

6. Remove the camshaft brackets.

7. Remove the camshaft.

8. Remove the tappet not within tolerance.

Determining dimension Y.

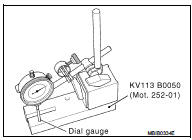

Set up the following assembly using KV113B0050 (Mot. 252-01) (Commercial service tool) or equivalent tool and dial gauge, then calibrate the gauge.

9. Raise the gauge extension (without modifying the position of the magnetic support/gauge assembly), then slide in the tappet to be measured.

• Note dimension (Y) and repeat the operation for the tappets where the valve clearance is not within tolerance.

• Refer to the Replacement Parts Catalogue for the vehicle concerned to select the various thicknesses of the tappet(s).

10. Check the valve clearance again.

11. Remove the camshaft brackets.

12. Remove the camshaft.

13. Remove the tappet(s) not within tolerance.

14. Grease the underside of the tappets and the camshaft brackets.

15. Degrease the gasket faces (of the cylinder head and brackets 1 and 6). They should be clean, dry and free from grease (in particular, remove finger marks).

16. Lay four beads of Loctite with a width of 1 mm (0.04 in) on brackets 1 and 6 of the cylinder head.

17. Install the camshaft.

18. Install the camshaft brackets (these are numbered from 1 to 6 and bearing (1) should be positioned on the flywheel end).

: 11 N·m (1.1 kg-m, 8 ft-lb)

: 11 N·m (1.1 kg-m, 8 ft-lb)

Basic inspection

Basic inspection

...

Symptom diagnosis

Symptom diagnosis

Noise, vibration and harshnesS (NVH) Troubleshooting

NVH Troubleshooting - Engine Noise

Use the Chart Below to Help You Find the Cause

of the Symptom

1. Locate the area where noise occurs.

2. C ...

Other materials:

Front wheel hub and knuckle

Exploded View

1. Steering knuckle

2. Splash guard

3. Hub bolt

4. Wheel hub assembly (Bearing-integrated

type)

5. Disc rotor

6. Wheel hub lock nut

7. Adjusting cap

8. Cotter pin

A. Tightening must be done following the installation procedure. Refer to

FAX-11, "Removal and Insta ...

Front wiper motor lo circuit

Component Function Check

1.CHECK FRONT WIPER LO OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Lo : Front wiper (LO) operation

Off : Stop the front wiper.

Is front wiper (LO) operation norma ...

Battery inspection

How to Handle Battery

CAUTION:

• If it becomes necessary to start the engine with a booster battery and jumper

cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to

battery terminals for good

contact.

• Never add distilled water t ...