Nissan Juke Service and Repair Manual : C1176 stop lamp SW2

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1176” detected? YES >> Proceed to BRC-199, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

NOTE

:

DTC “C1176” may be detected when the brake pedal and the accelerator pedal are

simultaneously depressed

for 1 minute or more while driving the vehicle. This is not a malfunction.

1.INTERVIEW FROM THE CUSTOMER

Check if the brake pedal and the accelerator pedal are simultaneously depressed for 1 minute or more while driving the vehicle.

Is there such a history? YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM SELF-DIAGNOSIS

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Start the engine.

CAUTION:

Never start the vehicle.

4. Depress the brake pedal several times.

5. Perform self-diagnosis for “ABS”.

Is DTC “C1176” detected? YES >> GO TO 3.

NO >> INSPECTION END

3.CHECK BRAKE SWITCH/BRAKE PEDAL POSITION SWITCH CLEARANCE

1. Turn the ignition switch OFF.

2. Check brake switch/brake pedal position switch clearance.

- LHD: Refer to BR-9, "Inspection and Adjustment".

- RHD: Refer to BR-77, "Inspection and Adjustment".

Is the inspection result normal? YES >> GO TO 5.

NO >> Adjust brake switch/brake pedal position switch clearance. GO TO 4.

• LHD: Refer to BR-77, "Inspection and Adjustment".

• RHD: Refer to BR-77, "Inspection and Adjustment".

4.CHECK DATA MONITOR (1)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Start the engine.

CAUTION:

Never start the vehicle.

4. Select “ABS”, “DATA MONITOR” and “STOP LAMP SW2” according to this order. Check that data monitor displays “On” or “Off” when brake pedal is depress or release. Refer to BRC-136, "Reference Value".

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK BRAKE SWITCH/BRAKE PEDAL POSITION SWITCH

Check brake switch/brake pedal position switch. Refer to BRC-177, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace brake switch/brake pedal position switch. GO TO 6.

• LHD: Refer to BR-21, "Removal and Installation".

• RHD: Refer to BR-89, "Removal and Installation".

6.CHECK DATA MONITOR (2)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Start the engine.

CAUTION:

Never start the vehicle.

4. Select “ABS”, “DATA MONITOR” and “STOP LAMP SW2” according to this order. Check that data monitor displays “On” or “Off” when brake pedal is depress or release. Refer to BRC-136, "Reference Value".

Is the inspection result normal? YES >> INSPECTION END NO >> GO TO 7.

7.CHECK CONNECTOR AND TERMINAL

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

4. Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

5. Disconnect brake switch/brake pedal position switch harness connector.

6. Check brake switch/brake pedal position switch harness connector for disconnection or looseness.

7. Check brake switch/brake pedal position switch pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts. GO TO 8.

8.CHECK DATA MONITOR (3)

With CONSULT-III.

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect brake switch/brake pedal position switch harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Start the engine.

CAUTION:

Never start the vehicle.

6. Select “ABS”, “DATA MONITOR” and “STOP LAMP SW2” according to this order. Check that data monitor displays “On” or “Off” when brake pedal is depress or release. Refer to BRC-136, "Reference Value".

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 11.

9.CHECK BRAKE SWITCH/BRAKE PEDAL POSITION SWITCHCIRCUIT (1)

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> Repair or replace error-detected parts. GO TO 10.

10.CHECK BRAKE SWITCH/BRAKE PEDAL POSITION SWITCH CIRCUIT (2)

1. Turn the ignition switch OFF.

2. Disconnect brake switch/brake pedal position switch harness connector.

3. Check continuity between ABS actuator and electric unit (control unit) harness connector and brake switch/brake pedal position switch harness connector.

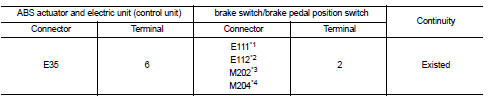

*1: Brake switch (LHD models and RHD models with CVT) *2: Brake pedal position switch (LHD models and RHD models with CVT) *3: Brake switch (RHD models with M/T) *4: Brake pedal position switch (RHD models with M/T)

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> Repair or replace error-detected parts. GO TO 11.

11.CHECK DATA MONITOR (4)

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect brake switch/brake pedal position switch harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Start the engine.

CAUTION:

Never start the vehicle.

6. Select “ABS”, “DATA MONITOR” and “STOP LAMP SW2” according to this order. Check that data monitor displays “On” or “Off” when brake pedal is depress or release. Refer to BRC-136, "Reference Value".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

Component Inspection

1.CHECK BRAKE SWITCH/BRAKE PEDAL POSITION SWITCH

1. Turn ignition switch OFF.2. Disconnect brake switch/brake pedal position switch harness connector.

3. Check continuity between brake switch/brake pedal position switch harness connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake switch/brake pedal position switch.

• LHD: Refer to BR-21, "Removal and Installation".

• RHD: Refer to BR-89, "Removal and Installation".

C1166, C1167 SV system

C1166, C1167 SV system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

U1000 can comm circuit

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Where to go for service

If maintenance service is required or your vehicle appears to malfunction, have

the systems checked and serviced by a NISSAN dealer.

NISSAN technicians are well-trained specialists and are kept up-to-date with

the latest service information through technical bulletins, service tips, and in-deal ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing STC-17, "Diagnostic

Work Sheet" and reproduce symptoms as well as fully understand it. Ask customer

about ...

Floor trim

Exploded View

LHD models

1. Floor carpet

2. Carpet hook

3. Trim clip

4. Column hole cover

5. Harness clip

6. Front floor spacer RH

7. Front floor spacer LH

8. Rear floor spacer LH

9. Rear floor spacer RH

: Clip

: Pawl

Removal and Installation

REMOVAL

CAUTION:

• When removing ...