Nissan Juke Service and Repair Manual : Brake piping

Front : Exploded View

WITHOUT ESP

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock plate

8. Brake hose

9. Union bolt

10. Copper washer

A. To rear brake tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

WITH ESP

MR16DDT

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock plate

8. Brake hose

9. Union bolt

10. Copper washer

A. To rear brake tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

HR16DE

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock plate

8. Brake hose

9. Union bolt

10. Copper washer

A. To rear brake tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

K9K

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock plate

8. Brake hose

9. Union bolt

10. Copper washer

A. To rear brake tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Front : Hydraulic Piping

2WD

1. Brake booster

2. Master cylinder assembly

3. Front disc brake

4. ABS actuator and electric unit (control

unit)

5. Connector

6. Rear disc brake

A. Brake tube

B. Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

4WD

1. Brake booster

2. Master cylinder assembly

3. Front disc brake

4. ABS actuator and electric unit (control

unit)

5. Connector

6. Rear disc brake

A. Brake tube

B. Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

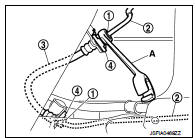

Front : Removal and Installation

REMOVAL

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Remove tires.

2. Drain brake fluid. Refer to BR-80, "Draining".

3. Loosen the flare nut (1) with a flare nut wrench (A) and separate the brake tube (2) from the brake hose (3).

CAUTION:

• Never scratch the flare nut and the brake tube.

• Never bend sharply, twist or strongly pull out the brake hoses and tubes.

• Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt (1) and copper washers (2), and remove the brake hose (3) from the brake caliper assembly.

5. Remove the lock plate (4) and remove the brake hose.

INSTALLATION

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Assemble the union bolt (1) and the copper washer (2) to the brake hose.

CAUTION:

Never reuse the copper washe

r.

2. Align the brake hose pin (A) with the brake caliper assembly projection (B), and tighten the union bolt (1) to the specified torqu

3. Install the brake tube (2) to the brake hose (1), temporarily tighten the flare nut (3) by hand until it does not rotate further, and fix the brake hose to the bracket (5) with the lock plate (4).

CAUTION:

Check that all brake hoses and brake tubes are not twisted

and bent.

4. Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-81, "Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

6. Install tires. Refer to WT-7, "Exploded View".

7. Perform inspection after installation. Refer to BR-97, "FRONT : Inspection".

Front : Inspection

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interference with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any

abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

Rear : Exploded View

2WD (MR16DDT, HR16DE)

1. Brake tube

2. Brake hose A

3. Lock plate

4. Brake hose bracket

5. Union bolt

6. Brake hose B

7. Copper washer

A. To connector

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

N·m (kg-m, in-lb)

N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

2WD (K9K)

1. Brake tube

2. Brake hose A

3. Lock plate

4. Brake hose bracket

5. Union bolt

6. Brake hose B

7. Copper washer

A. To connector

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

4WD

1. Brake tube

2. Brake hose A

3. Lock plate

4. Brake hose bracket

5. Brake hose B

6. Union bolt

7. Copper washer

A. To connector

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Rear : Hydraulic Piping

2WD

1. Brake booster

2. Master cylinder assembly

3. Front disc brake

4. ABS actuator and electric unit (control

unit)

5. Connector

6. Rear disc brake

A. Brake tube

B. Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

4WD

1. Brake booster

2. Master cylinder assembly

3. Front disc brake

4. ABS actuator and electric unit (control

unit)

5. Connector

6. Rear disc brake

A. Brake tube

B. Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

Rear : Removal and Installation

REMOVAL

2WD

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Remove tires.

2. Drain brake fluid. Refer to BR-80, "Draining".

3. Loosen the flare nut (1) with a flare nut wrench (A) and separate the brake tube (2) from the brake hose A (3).

CAUTION:

• Never scratch the flare nut and the brake tube.

• Never bend sharply, twist or strongly pull out the brake hoses and tubes.

• Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt

.

4. Remove the lock plate (4) and remove the brake hose A.

5. Loosen the flare nut (1) with a flare nut wrench (A) and separate the brake tube (2) from the hose B (3).

CAUTION:

• Never scratch the flare nut and the brake tube.

• Never bend sharply, twist or strongly pull out the brake hoses and tubes.

• Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt

.

6. Remove the lock plate (4) from brake hose bracket (5).

7. Remove the union bolt (1) and copper washers (2), and remove the brake hose B (3) from the brake caliper assembly.

4WD

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Remove tires.

2. Drain brake fluid. Refer to BR-80, "Draining".

3. Loosen the flare nut (1) with a flare nut wrench (A) and separate the brake tube (2) from the hose A (3).

CAUTION:

• Never scratch the flare nut and the brake tube.

• Never bend sharply, twist or strongly pull out the brake hoses and tubes.

• Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

4. Remove the lock plate (4) and remove the brake hose A.

5. Loosen the flare nut (1) with a flare nut wrench (A) and separate the brake tube (2) from the hose B (3).

CAUTION:

• Never scratch the flare nut and the brake tube.

• Never bend sharply, twist or strongly pull out the brake hoses and tubes.

• Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

6. Remove the lock plate (4) from brake hose bracket (5).

7. Remove the union bolt (1) and copper washers (2), and remove the brake hose B (3) from the brake caliper assembly.

INSTALLATION

2WD

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Assemble the union bolt (1) and the copper washer (2) to the brake hose B.

CAUTION:

Never reuse the copper washer.

2. Align the brake hose B L-pin (A) with the brake caliper assembly hole (B), and tighten the union bolt (1) to the specified torque.

3. Install the brake tube (2) to the brake hose B (1), temporarily tighten the flare nut (3) by hand until it does not rotate further, and fix the brake hose B to the brake hose bracket (5) with the lock plate (4).

CAUTION:

Check that all brake hoses and brake tubes are not twisted

and bent.

4. Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

5. Install the brake tube (2) to the brake hose A (1), temporarily tighten the flare nut (3) by hand until it does not rotate further, and fix the brake hose with the lock plate (4).

CAUTION:

Check that all brake hoses and brake tubes are not twisted

and bent.

6. Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

7. Refill with new brake fluid and perform the air bleeding. Refer to BR-81, "Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

8. Install tires. Refer to WT-7, "Exploded View".

9. Perform inspection after installation. Refer to BR-105, "REAR : Inspection".

4WD

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may

seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface. For brake

component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

1. Assemble the union bolt (1) and the copper washer (2) to the brake hose B.

CAUTION:

Never reuse the copper washer.

2. Align the brake hose B L-pin (A) with the brake caliper assembly hole (B), and tighten the union bolt (1) to the specified torque.

3. Install the brake tube (2) to the brake hose B (1), temporarily tighten the flare nut (3) by hand until it does not rotate further, and fix the brake hose B to the brake hose bracket (5) with the lock plate (4).

CAUTION:

Check that all brake hoses and brake tubes are not twisted

and bent.

4. Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

5. Install the brake tube (2) to the brake hose A (3), temporarily tighten the flare nut (1) by hand until it does not rotate further, and fix the brake hose A to the bracket with the lock plate (4).

CAUTION:

Check that all brake hoses and brake tubes are not twisted

and bent.

6. Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

7. Refill with new brake fluid and perform the air bleeding. Refer to BR-81, "Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

8. Install tires. Refer to WT-7, "Exploded View".

9. Perform inspection after installation. Refer to BR-105, "REAR : Inspection".

Rear : Inspection

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION

:

Retighten the applicable connection to the specified torque and repair any

abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

Brake pedal

Brake pedal

Exploded View

WITHOUT ESP

1. Clevis pin

2. Brake pedal assembly

3. Brake pedal pad

4. Stop lamp switch

5. Clip

6. Snap pin

: Apply multi-purpose grease.

: N·m (kg-m, ft-lb)

WITH ESP

...

Brake master cylinder

Brake master cylinder

Exploded View

2WD

1. Reservoir cap

2. Oil strainer

3. Reservoir tank

4. Cylinder body

5. O-ring

6. Grommet

7. Pin

: Apply polyglycol ether

lubricant

: Apply brake fluid.

: N·m (kg-m ...

Other materials:

Component parts

Charging system

CHARGING SYSTEM : Component Parts Location

1. Charge warning lamp (On the combination

meter)

2. Alternat

CHARGING SYSTEM : Component Description

Power generation voltage variable control system

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM : Component

Parts Location

N ...

P0222, P0223 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0643 ,first perform the trouble

diagnosis for DTC P0643.

Refer to EC-274, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, alw ...

LAN System can system (type 5)

DTC/CIRCUIT DIAGNOSIS

Main line between IPDM-E and DLC circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose

connection (connector s ...