Nissan Juke Service and Repair Manual : Blower motor

Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom (A, B or C).

Which symptom is detected? A >>GO TO 2.

B >>GO TO 11.

C >> GO TO 13.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check following fuses.

- 10A fuse [No. 15, located in fuse block (J/B)] - 15A fuses [Nos. 14 and 16, located in the fuse block (J/B)]

NOTE

:

Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

3.CHECK BLOWER MOTOR POWER SUPPLY

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK BLOWER RELAY

1. Turn ignition switch OFF.

2. Check blower relay. Refer to HAC-173, "Component Inspection (Blower Relay)".

Is the inspection result normal? YES >> Repair harness or connector between blower motor and fuse.

NO >> Replace blower relay.

5.CHECK FAN CONTROL AMP. POWER SUPPLY (SOURCE) CIRCUIT

1. Turn ignition switch OFF.

2. Connect blower motor connector.

3. Disconnect fan control amp. connector.

4. Turn ignition switch ON.

5. Check voltage between fan control amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.CHECK FAN CONTROL AMP. POWER SUPPLY (SOURCE) CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect blower motor connector.

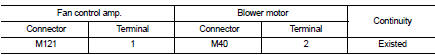

3. Check continuity between fan control amp. harness connector and blower motor harness connector.

Is the inspection result normal? YES >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

NO >> Repair harness or connector.

7.CHECK FAN CONTROL AMP. GROUND (DRAIN) CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Check continuity between fan control amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair harness or connector.

8.CHECK FAN CONTROL AMP. CONTROL SIGNAL (GATE) CIRCUIT FOR OPEN

1. Disconnect A/C auto amp. connector.

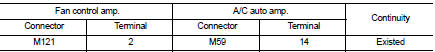

2. Check continuity between fan control amp. harness connector and A/C auto amp. harness connector.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK FAN CONTROL AMP. CONTROL SIGNAL (GATE) CIRCUIT FOR SHORT

Check continuity between fan control amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair harness or connector.

10.CHECK FAN CONTROL AMP.

Check fan control amp. Refer to HAC-173, "Component Inspection (Fan Control Amp.)".

Is the inspection result normal? YES >> Replace A/C auto amp. Refer to HAC-188, "Removal and Installation".

NO >> Replace fan control amp. Refer to HAC-194, "Removal and Installation".

11.CHECK A/C AUTO AMP. IGNITION POWER SUPPLY FEEDBACK SIGNAL

1. Turn ignition switch ON.

2. Check voltage between A/C auto amp. harness connector and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair harness or connector between A/C auto amp. and fuse.

12.CHECK BLOWER MOTOR FEEDBACK SIGNAL CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect blower motor connector and A/C auto amp. connector.

3. Check continuity between blower motor harness connector and A/C auto amp. harness connector.

Is the inspection result normal? YES >> Replace A/C auto amp. Refer to HAC-188, "Removal and Installation".

NO >> Repair harness or connector.

13.CHECK BLOWER MOTOR FEEDBACK SIGNAL CIRCUIT AND FAN CONTROL AMP. POWER SUPPLY (SOURCE) CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect following connectors.

- Blower fan motor

- Fan control amp.

- A/C auto amp.

3. Check continuity between blower motor harness connector and ground.

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair harness or connector.

14.CHECK FAN CONTROL AMP. CONTROL SIGNAL (GATE) CIRCUIT FOR SHORT TO POWER SUPPLY

Check harness between fan control amp. harness connector and A/C auto amp. harness connector for short to power supply.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair harness or connector.

Component Inspection (Blower Motor)

1.CHECK BLOWER MOTOR

1. Remove blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2. Check that there is not any mixing foreign object in the blower motor.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2.CHECK BLOWER MOTOR

Check that there is not breakage or damage in the blower motor.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

3.CHECK BLOWER MOTOR

Check that blower motor turns smoothly.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

Component Inspection (Blower Relay)

1.CHECK BLOWER RELAY

1. Remove blower relay. Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

2. Check continuity between blower relay terminal 3 and 5 when the voltage is supplied between terminal 1 and 2.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower relay.

Component Inspection (Fan Control Amp.)

1.CHECK FAN CONTROL AMP.

1. Remove fan control amp. Refer to HAC-194, "Removal and Installation".

2. Check continuity between fan control amp. terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace fan control amp. Refer to HAC-194, "Removal and Installation".

Blower fan on signal

Blower fan on signal

Component Function Check

1.CHECK BLOWER FAN ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “FAN ON SIG” in “DATA MONITOR” ...

Magnet clutch

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosi ...

Other materials:

Power door lock system

System Diagram

System Description

DOOR LOCK FUNCTION

• The door lock and unlock switch (driver side) is build into power window

main switch.

• Interlocked with the locking operation of door lock and unlock switch, door

lock actuators of all doors are

locked.

• Interlocked with the unlock ...

Air breather hose

MR16DDT : Exploded View

1. Clip

2. Air breather hose

3. 2 way connector

MR16DDT : Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-26, "Removal and Installation".

2. Remove clips (1).

: Vehicle front

3. Remove air breather hose from the 2 way connector. ...

Basic inspection

Radiator

Inspection

Check radiator for mud or clogging. If necessary, clean radiator as follows.

CAUTION:

• Be careful not to bend or damage the radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as

radiator fan, radiator

shroud and horns. Then tap ...