Nissan Juke Service and Repair Manual : A/C unit assembly

Exploded View (Automatic Air Conditioning)

REMOVAL

LHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Sub defroster door

5. Center ventilator and defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Sub harness

10. Power transistor

11. Upper intake case

12. Intake door

13. Lower intake case

14. Blower case LH

15. Blower case RH

16. Blower motor

17. Intake seal

18. A/C unit case RH

19. Air conditioner filter

20. Filter cover

21. Case packing

22. Intake sensor

23. Evaporator

24. Plate

25. Expansion valve grommet

26. O-ring

27. Expansion valve

28. Evaporator cover

29. Heater hose

30. Clamp

31. Heater pipe grommet

32. Heater pipe support

33. Heater core

34. A/C unit case LH

35. Aspirator duct

36. Aspirator

37. Foot door

38. Foot door rod

39. Side ventilator door

40. Air mix door guide

41. Upper air mix door

42. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

RHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

RHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Sub defroster door

5. Center ventilator and defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Sub harness

10. Power transistor

11. Upper intake case

12. Intake door

13. Lower intake case

14. Blower case LH

15. Blower case RH

16. Blower motor

17. Intake seal

18. A/C unit case RH

19. Case packing

20. Intake sensor

21. Evaporator

22. Plate

23. Expansion valve grommet

24. O-ring

25. Expansion valve

26. Evaporator cover

27. Heater hose

28. Clamp

29. Heater pipe grommet

30. Heater pipe support

31. Filter cover

32. Air conditioner filter

33. Heater core

34. A/C unit case LH

35. Aspirator

36. Aspirator duct

37. Foot door

38. Foot door rod

39. Side ventilator door

40. Air mix door guide

41. Upper air mix door

42. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

LHD models (2WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (2WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Upper intake case

10. Intake door

11. Lower intake case

12. Blower case LH

13. Blower case RH

14. Blower motor

15. Blower motor cover

16. Intake seal

17. A/C unit case RH

18. Air conditioner filter

19. Filter cover

20. Case packing

21. Evaporator cover

22. Intake sensor

23. Evaporator

24. O-ring

25. Expansion valve grommet

26. Expansion valve

27. Fan control amp.

28. Heater pipe support

29. Clamp

30. Heater hose

31. Heater pipe grommet

32. Heater core side packing

33. Heater core

34. A/C unit case LH

35. Aspirator duct

36. Aspirator

37. Side ventilator door

38. Foot door

39. Center lib case

40. Max. cool door

41. Upper air mix door

42. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

RHD models (2WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

RHD models (2WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Upper intake case

10. Intake door

11. Lower intake case

12. Blower case LH

13. Blower case RH

14. Blower motor

15. Blower motor cover

16. Intake seal

17. A/C unit case RH

18. Case packing

19. Evaporator cover

20. Intake sensor

21. Evaporator

22. O-ring

23. Expansion valve grommet

24. Expansion valve

25. Fan control amp.

26. Heater pipe support

27. Clamp

28. Heater hose

29. Heater pipe grommet

30. Air conditioner filter

31. Filter cover

32. Heater core

33. A/C unit case LH

34. Aspirator

35. Aspirator duct

36. Side ventilator door

37. Foot door

38. Center lib case

39. Max. cool door

40. Upper air mix door

41. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Exploded View (Manual Air Conditioning)

REMOVAL

LHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Sub harness

10. Blower fan resistor

11. Upper Intake case

12. Intake door

13. Lower intake case

14. Blower case LH

15. Blower case RH

16. Blower motor

17. Intake seal

18. A/C unit case RH

19. Air conditioner filter

20. Filter cover

21. Case packing

22. Thermo control amp.

23. Evaporator

24. Plate

25. Expansion valve grommet

26. O-ring

27. Expansion valve

28. Evaporator cover

29. Heater hose

30. Clamp

31. Heater pipe grommet

32. Heater pipe support

33. Heater core

34. A/C unit case LH

35. Foot door

36. Foot door rod

37. Side ventilator door

38. Air mix door guide

39. Upper air mix door

40. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

RHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

RHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Sub harness

10. Blower fan resistor

11. Upper intake case

12. Intake door

13. Sub intake door

14. Lower Intake case

15. Blower case LH

16. Blower case RH

17. Blower motor

18. Intake seal

19. A/C unit case RH

20. Case packing

21. Thermo control amp.

22. Evaporator

23. Plate

24. Expansion valve grommet

25. O-ring

26. Expansion valve

27. Evaporator cover

28. Heater hose

29. Clamp

30. Heater pipe grommet

31. Heater pipe support

32. Filter cover

33. Air conditioner filter

34. Heater core

35. A/C unit case LH

36. Foot door

37. Foot door rod

38. Side ventilator door

39. Air mix door guide

40. Upper air mix door

41. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

LHD models (2WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (2WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Upper intake case

10. Intake door

11. Lower intake case

12. Blower case LH

13. Blower case RH

14. Blower motor

15. Blower motor cover

16. Intake seal

17. A/C unit case RH

18. Air conditioner filter

19. Filter cover

20. Case packing

21. Evaporator cover

22. Thermo control amp.

23. Evaporator

24. O-ring

25. Expansion valve grommet

26. Expansion valve

27. Blower fan resistor

28. Heater pipe support

29. Clamp

30. Heater hose

31. Heater pipe grommet

32. Heater core side packing

33. Heater core

34. A/C unit case LH

35. Side ventilator door

36. Foot door

37. Center lib case

38. Max. cool door

39. Upper air mix door

40. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

REMOVAL

RHD models (2WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: Clip

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

RHD models (2WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Center ventilator door

5. Defroster door

6. Side ventilator seal LH

7. Lower attachment case

8. Side ventilator seal RH

9. Upper intake case

10. Intake door

11. Lower intake case

12. Blower case LH

13. Blower case RH

14. Blower motor

15. Blower motor cover

16. Intake seal

17. A/C unit case RH

18. Case packing

19. Evaporator cover

20. Thermo control amp.

21. Evaporator

22. O-ring

23. Expansion valve grommet

24. Expansion valve

25. Blower fan resistor

26. Heater pipe support

27. Clamp

28. Heater hose

29. Heater pipe grommet

30. Air conditioner filter

31. Filter cover

32. Heater core

33. A/C unit case LH

34. Ventilator door side

35. Foot door

36. Center lib case

37. Max. cool door

38. Upper air mix door

39. Lower air mix door

A. To water outlet

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

A/C unit assembly : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Drain engine coolant from cooling system. Refer to CO-11, "Draining".

3. Remove cowl top extension. Refer to EXT-20, "Removal and Installation".

4. Remove mounting nut, and then move lower dash insulator aside.

: Nut

: Nut

: Vehicle front

: Vehicle front

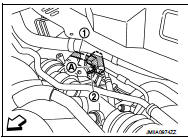

5. Remove mounting bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from expansion valve. Refer to HA-116, "EXPANSION VALVE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

: Vehicle front

: Vehicle front

6. Remove clamps (1), and then disconnect heater hose (2) from A/C unit assembly.

: Vehicle front

: Vehicle front

7. Remove instrument panel assembly. Refer to IP-13, "Removal and Installation".

8. Remove side ventirator duct. Refer to VTL-12, "SIDE VENTILATOR DUCT : Removal and Installation".

9. Remove mounting bolts (A) of ground wire LH side and mounting bolt (B) of ground wire RH side.

10. Remove rear heater duct 1. Refer to VTL-13, "REAR HEATER DUCT 1 : Removal

and Installation". (LHD

models only)

11. Disconnect drain hose (1) from A/C unit assembly.

: Vehicle front

: Vehicle front

12. Remove mounting nuts (A), and then remove instrument stay.

: Vehicle front

: Vehicle front

13. Remove J/B fixing screws (A), and then remove J/B.

14. Remove BCM fixing screws (A), and then remove BCM.

15. Disconnect harness connectors and clips required to remove the steering member, and then move the vehicle harness to the position without hindrance for work.

16. Move steering column assembly to a position where it dose not inhibit work.

Refer to ST-10, "Removal

and Installation"

17. Remove mounting bolts (A) and (B), and then remove steering member (1) from

vehicle.

18. Remove A/C unit assembly from vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

NOTE:

Refer to CO-12, "Refilling" when filling radiator with engine coolant.

Evaporator : Removal and Installation

REMOVAL

1. Remove A/C unit assembly. Refer to HA-113, "A/C UNIT ASSEMBLY : Removal and Installation".

2. Disassemble A/C unit assembly, and then remove evaporator.

3. Remove intake sensor from evaporator. (automatic air conditioning) 4. Remove thermo control amp. from evaporator. (manual air conditioning) 5. Remove mounting bolts, and then remove expansion valve.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• When install the intake sensor (automatic air conditioning) or the thermo control amp. (manual air conditioning), set the same position before replacement.

• Never rotate the bracket insertion part when removing and installing the intake sensor (automatic air conditioning) or the thermo control amp. (manual air conditioning).

• Perform lubricant adjusting procedure after installing new evaporator. Refer to HA-78, "Lubricant Adjusting Procedure for Components Replacement Except Compressor".

Heater core : Removal and Installation

REMOVAL

1. Remove A/C unit assembly. Refer to HA-113, "A/C UNIT ASSEMBLY : Removal and Installation".

2. Remove heater pipe grommet and heater pipe support from A/C unit assembly.

3. Remove foot duct LH. Refer to VTL-14, "FOOT DUCT : Removal and Installation".

4. Remove heater core side packing. (for 2WD LHD and AWD LHD models only) 5. Slide heater core to leftward, and then remove heater core from A/C unit assembly.

INSTALLATION

Install in the reverse order of removal.

Expansion valve : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Remove cowl top extension. Refer to EXT-20, "Removal and Installation".

3. Remove mounting nut, and then move lower dash insulator aside.

: Nut

: Nut

: Vehicle front

: Vehicle front

4. Remove mounting bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from expansion valve. Refer to HA-116, "EXPANSION VALVE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

: Vehicle front

: Vehicle front

5. Remove mounting bolts (A), and then remove expansion valve from evaporator.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

Condenser

Condenser

Exploded View

1. Condenser

2. Condenser lower bracket RH

3. Condenser lower bracket LH

4. O-ring

5. Liquid tank braket

6. Liquid tank

7. Braket

8. O-ring

9. Refrigerant pressure senso ...

Service data and specifications (SDS

Service data and specifications (SDS

Compressor

Lubricant

Refrigerant

Engine Idling Speed

Refer to EC-449, "Idle Speed".

Belt Tension

Refer to EM-20, "Checking". ...

Other materials:

Precaution Necessary for Steering Wheel Rotation

after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

System

Manual air conditioning system : System Diagram

Manual air conditioning system : System Description

DESCRIPTION

• Manual air conditioning system is controlled by each function of thermo

control amp., BCM, ECM and IPDM

E/R.

• Fan speed of blower motor is changed by the combination of fan con ...

P0651 sensor power supply

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or r ...