Nissan Juke Service and Repair Manual : Turbocharger

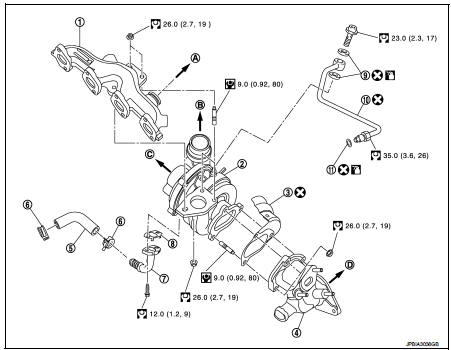

Exploded View

1. Exhaust manifold

2. Turbocharger

3. Gasket

4. Turbocharger outlet duct

5. Oil outlet hose

6. Clamp

7. Oil return pipe

8. Gasket

9. Washer

10. Oil supply tube

11. O-ring

A. To EGR tube

B. To air inlet pipe

C. To turbocharge air inlet pipe

D. To diesel particular filter assembly

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

: Should be lubricated with oil.

: Should be lubricated with oil.

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-280, "Exploded View".

2. Remove cowl top extension. Refer to EXT-20, "Exploded View".

3. Drain engine coolant. Refer to CO-62, "Draining".

4. Remove diesel particular filter assembly. Refer to EX-17, "Exploded View".

5. Remove EGR volume control valve housing. Refer to EM-283, "Exploded View".

6. Remove EGR cooler.

7. Disconnect 5th injector quick connector and harness connector.

8. Remove oil tubes.

9. Remove turbocharger outlet duct bracket.

10. Remove turbocharger assembly (1) as follows:

NOTE

:

After applying penetrative lubricant to the mounting nuts, check for the

penetration of the lubricant, and

then loosen the nuts (A) to remove.

a. Remove turbocharger oil outlet hose.

CAUTION:

Be careful not to deform each turbocharger piping when pulling

out the assembly.

11. Remove turbocharger outlet duct.

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Apply LOCTITE FRENETANCH or equivalent to the threads of the turbocharger oil

inlet pipe union to the cylinder

head.

Inspection

INSPECTION AFTER REMOVAL

Turbocharger

CAUTION:

When the compressor wheel, turbine wheel or rotor shaft is damaged, remove all

the fragments and

foreign matter left in the following passages in order to prevent a secondary

failure:

Suction side : Between turbocharger and air cleaner Exhaust side : Between turbocharger and outlet duct

INSPECTION AFTER INSTALLATION

Start engine and raise engine speed to check no exhaust emission leaks.

EGR valve

EGR valve

Exploded View

1. EGR valve assembly

2. Clamp

3. EGR tube

4. Air inlet tube

5. O-ring

6. Gasket

7. EGR cooler

8. Gasket

9. EGR volume control valve housing

10. Gasket

11. Electric t ...

Exhaust manifold

Exhaust manifold

Exploded View

1. Exhaust gas temperature sensor 1

2. Gasket

3. Exhaust manifold

4. Exhaust gas pressure sensor 1

A. To cylinder head

: N·m (kg-m, ft-lb)

: Always replace after every

disas ...

Other materials:

How to use remote keyless entry function

WARNING

• Radio waves could adversely affect electric medical equipment. Those who

use a pacemaker should contact the electric medical equipment manufacturer for the

possible influences before use.

• The Intelligent Key transmits radio waves when the buttons are pushed. The

FAA advises ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent

error detectability. Many

electronic control units are equipped onto vehicles, and each con ...

Body alignment

Body Center Marks (RHD Models)

A mark is placed on each part of the body to indicate the vehicle center.

When repairing the vehicle frame

(members, pillars, etc.) damaged by an accident which it enables more accurate

and effective repair by using

these marks together with body alignment speci ...